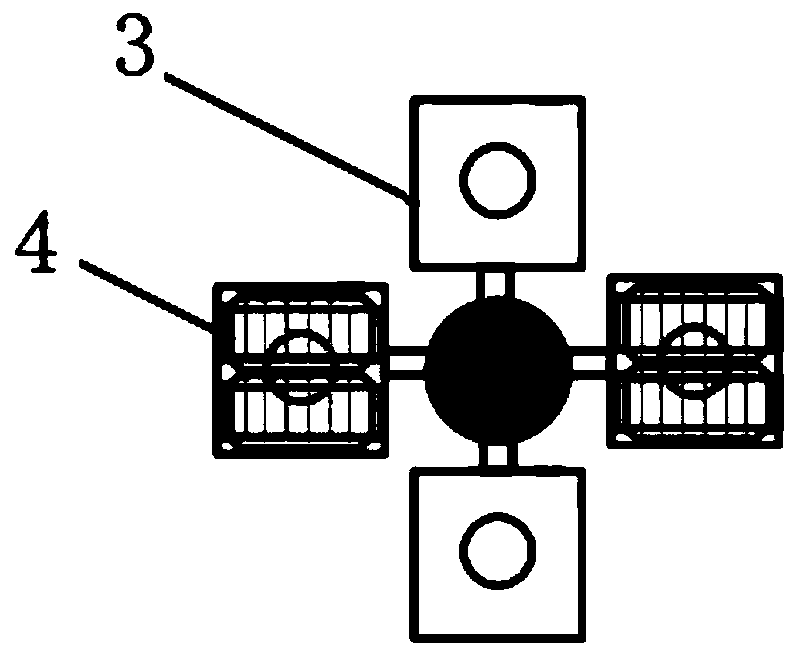

Rotary micro-channel plate etching device and etching method

A micro-channel plate and corrosion device technology, which is applied to multiple dynode electrode devices, dynodes, discharge tubes, etc., can solve the problems of poor display quality and low corrosion efficiency of micro-channel plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

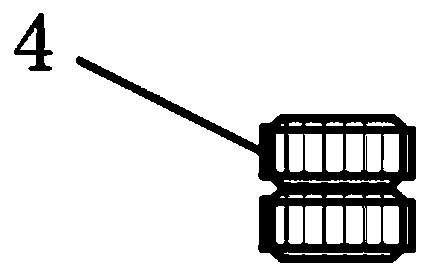

Method used

Image

Examples

Embodiment 2

[0094] Embodiment 2: the corrosion process of BJ type microchannel plate

[0095] Fill the corrosion tank with a nitric acid solution with a concentration of 1 equivalent, place the microchannel plate to be corroded in a rotary corrosion device, immerse it under the liquid surface, and start the rotary corrosion at a speed of 60 minutes / r for 30 minutes. minute.

[0096] After 30 minutes, the rotating device was stopped, and the liquid level in the corrosion tank was discharged to just submerge the microchannel plate, and then filled with 1 equivalent of nitric acid, and the next rotation corrosion was started after repeated twice, and the time was 30 minutes.

[0097] After 30 minutes, the rotating device was stopped, and the liquid level in the corrosion tank was discharged to just submerge the microchannel plate, and then filled with 1 equivalent of nitric acid, and the next rotation corrosion was started after repeated twice, and the time was 30 minutes.

[0098] After 20 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com