Active and passive combined safety system and method for nuclear power plant

A passive containment and safety system technology, applied in nuclear power generation, nuclear power plant auxiliary equipment, nuclear engineering, etc., can solve the problems of reducing dependence on power supply, poor personnel intervention, and relatively high power supply requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

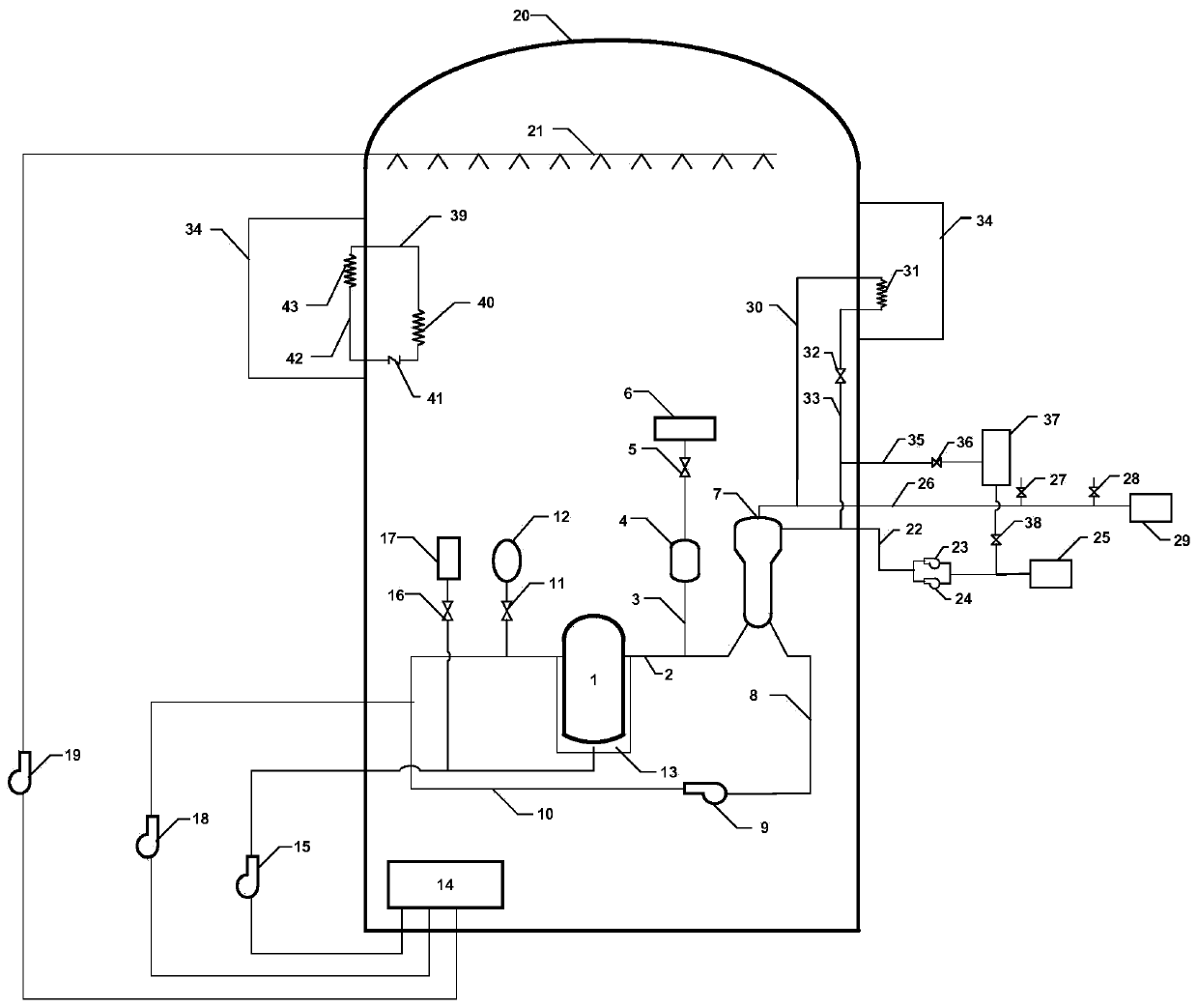

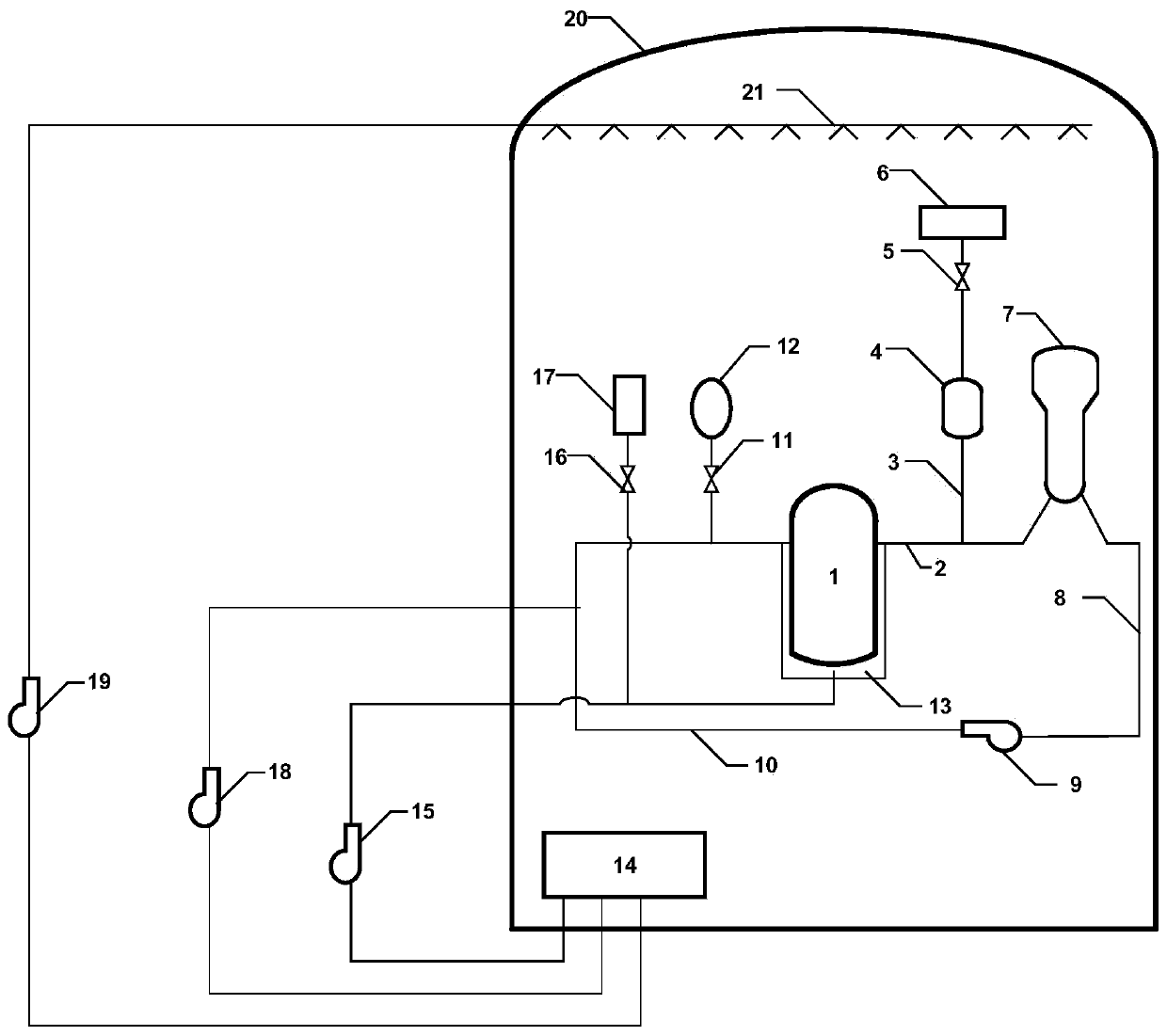

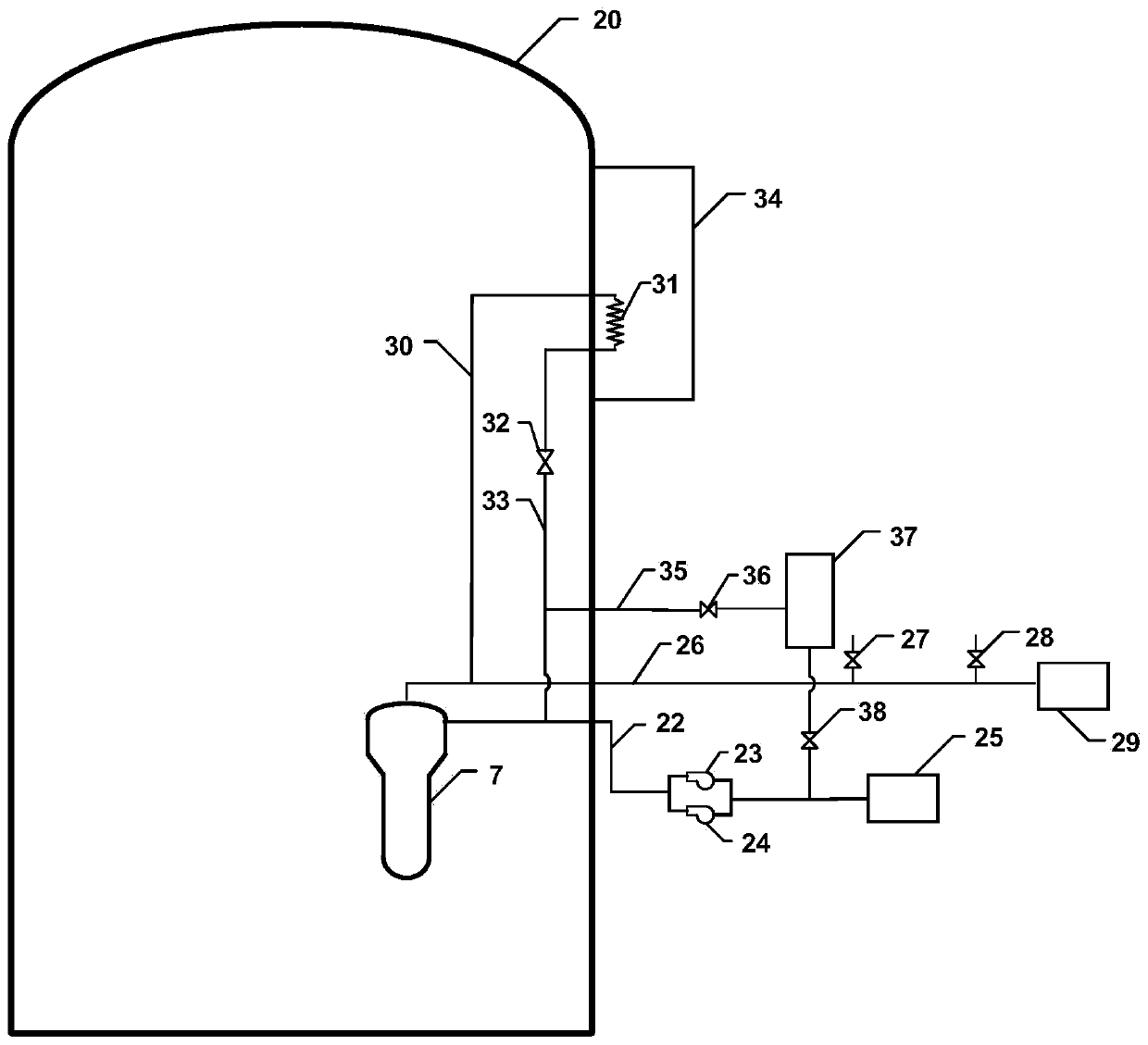

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0051] Such as figure 1 , 2, 3, and 4, a safety system for combining active and passive nuclear power plants provided by the present invention includes a core cooling system communicated with the cold section 10 side of the pressure vessel 1, connected to the bottom of the pressure vessel The reactor cavity water injection system connected by the water injection channel 13, the containment heat removal system located on the side of the cold section 10 of the pressure vessel, and the steam generator secondary side heat removal system located on the secondary side of the steam generator 7; the core cooling system One side of the reactor cavity water injection system, the containment heat removal system and the steam generator secondary side heat removal system is located inside the containment vessel 20 , and the other side is located outside t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com