Digital twinning method and device for numerical control skin stretch-forming machine

A twinning and digital technology, applied in the field of digital twinning of CNC skin stretching machines, can solve the problems that the production dynamics of physical equipment have not been applied, and the closed-loop communication between data models and physical equipment has not been formed, so as to achieve the effect of optimizing processing data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

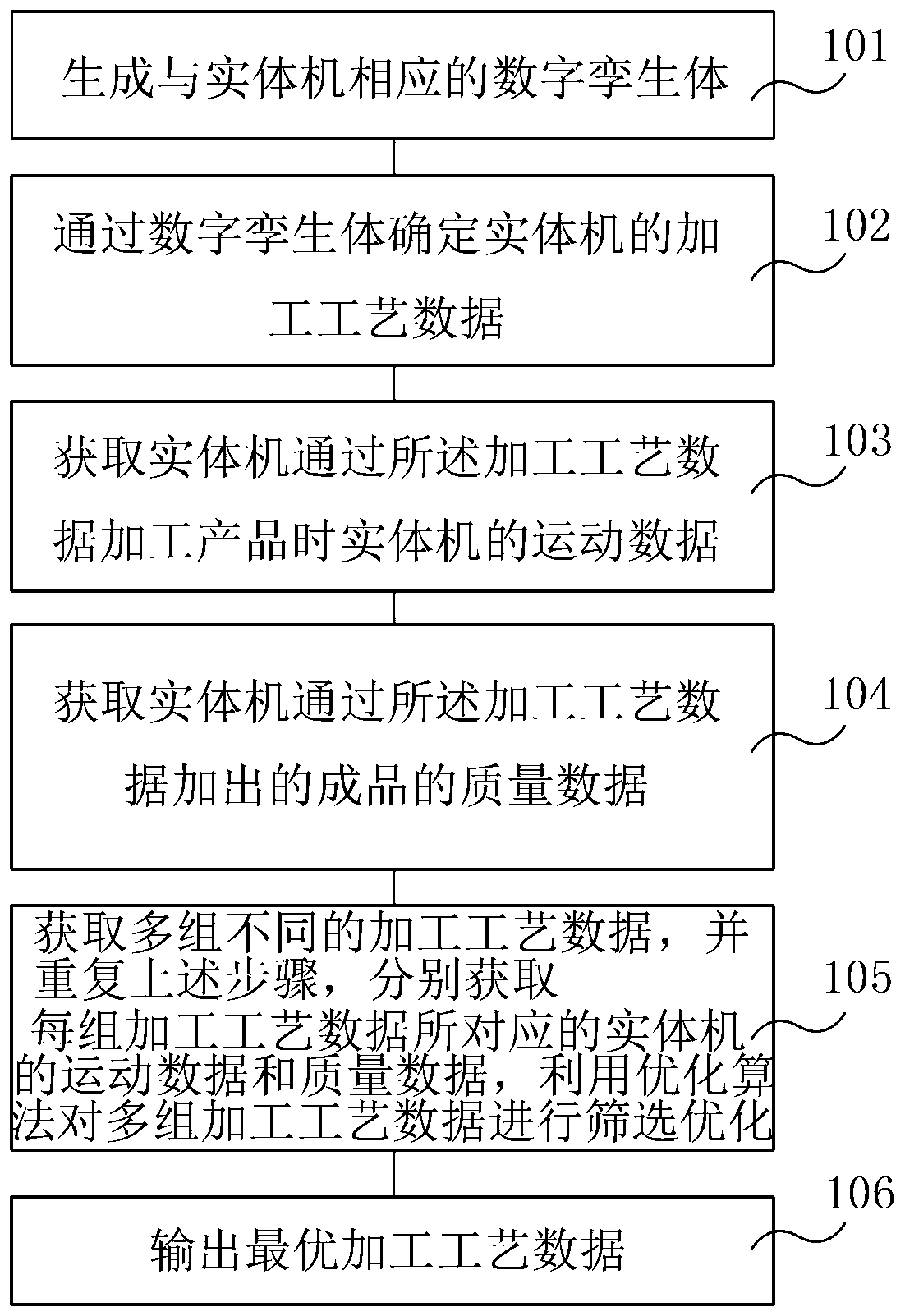

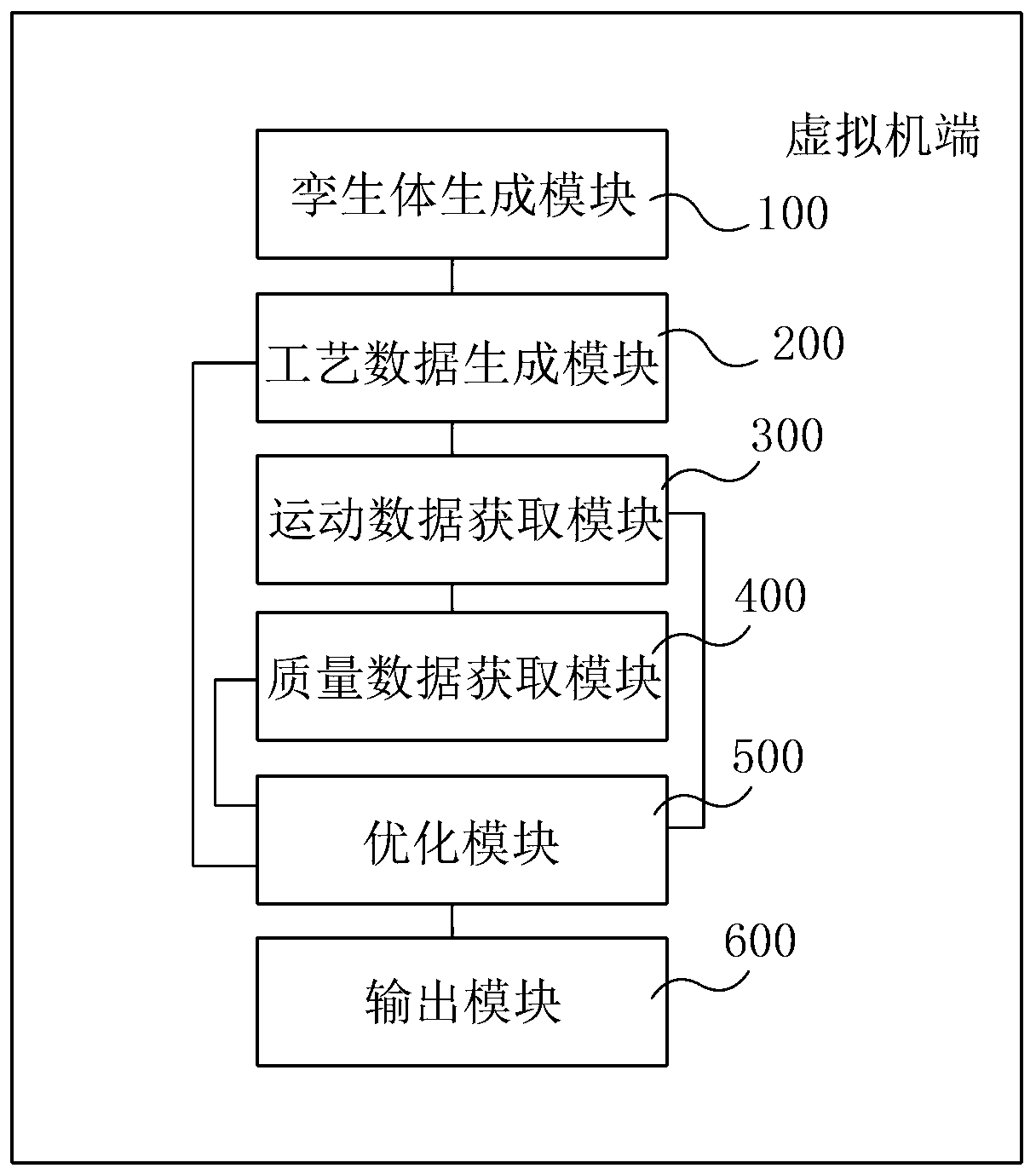

[0045] Please refer to figure 1 , which shows a flow chart of a digital twin method for a numerically controlled skin stretching machine according to the present invention. The digital twin method for a numerically controlled skin stretching machine is used on a virtual machine side, including:

[0046] 101. Generate a digital twin corresponding to the physical machine;

[0047] 102. Determine the processing technology data of the physical machine through the digital twin;

[0048] 103. Obtain the motion data of the physical machine when the physical machine processes the product through the processing technology data;

[0049] 104. Obtain the quality data of the finished product added by the physical machine through the processing technology data;

[0050] 105. Obtain multiple sets of different processing technology data, and repeat the above steps to respectively obtain the motion data and quality data of the physical machine corresponding to each set of processing technol...

Embodiment 2

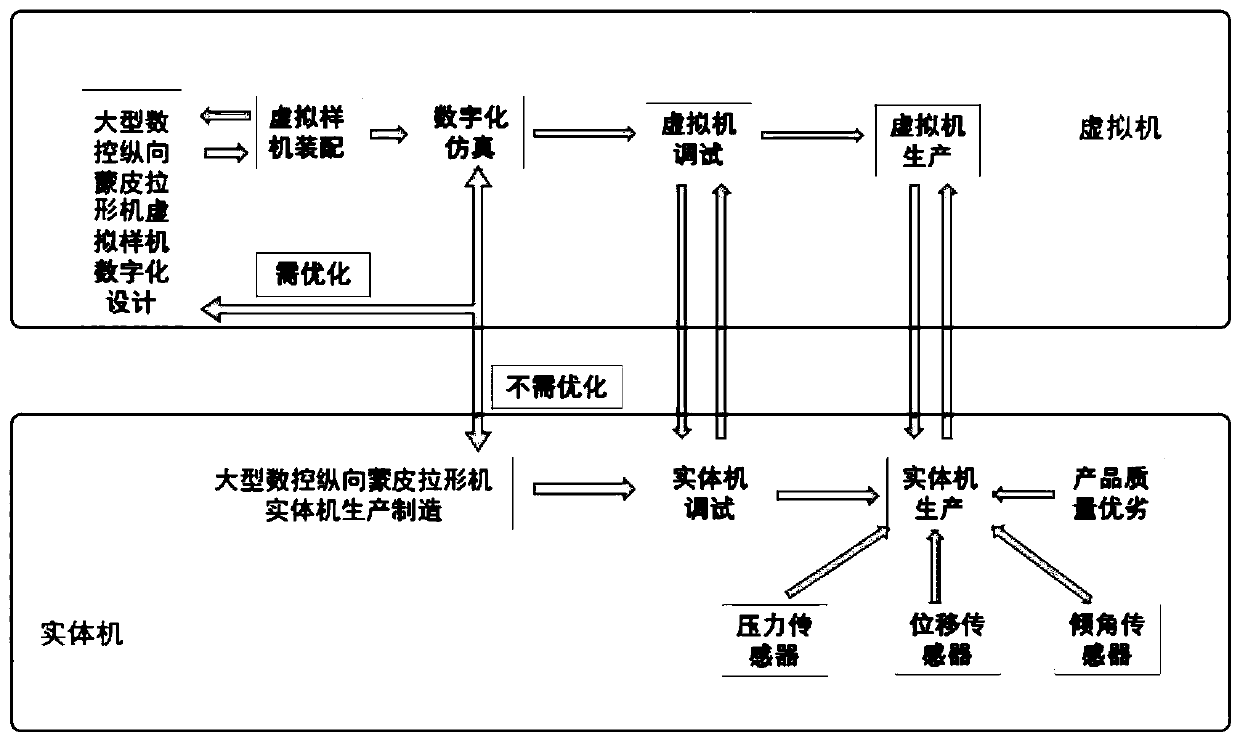

[0056] Further, please refer to figure 1 and figure 2 , another embodiment of the digital twin method of a numerically controlled skin stretching machine of the present invention, the processing data of the physical machine are determined through the digital twin body as follows:

[0057]During production, the digital twin is first used to identify the parameters of the product model size and unfold the reverse forming to determine the raw material size and process planning for stretch forming, and use the performance test data to simulate the tensile loading process considering springback compensation on the engineering simulation software. The virtual production and processing process data are determined through motion analysis and deformation coordination parameter matching.

[0058] In the above embodiment, in the specific production process, the digital twin is used to identify the parameters of the product model size and reverse forming to determine the raw material si...

Embodiment 3

[0060] Further, in another embodiment of the digital twin method of a numerically controlled skin stretching machine in the present invention, after the output optimal processing technology data is processed by the physical machine, the motion data and quality corresponding to the optimal processing technology data are The data is returned to the virtual machine side for iterative optimization, and the iterative optimization is used to determine more optimized processing technology data in the digital twin.

[0061] In the above-mentioned embodiment, after the processing technology data is generated for the first time, the corresponding motion data and quality data are obtained through production on the physical machine, and the obtained data will be used in the iterative optimization of the virtual machine side, so that the next generated The processing technology is more excellent, and the more excellent processing technology is repeatedly used to produce products on the phys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com