Glass kettle and capacitive water level detection device and method thereof

A technology of water level detection and capacitance detection, which is applied in measuring devices, water boiling appliances, liquid/fluid solid measurement, etc. It can solve the problems of non-conduction or conductivity drop, large voltage difference, scale wrapping, etc., and achieve real-time detection And accurate, high safety factor, healthy water effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

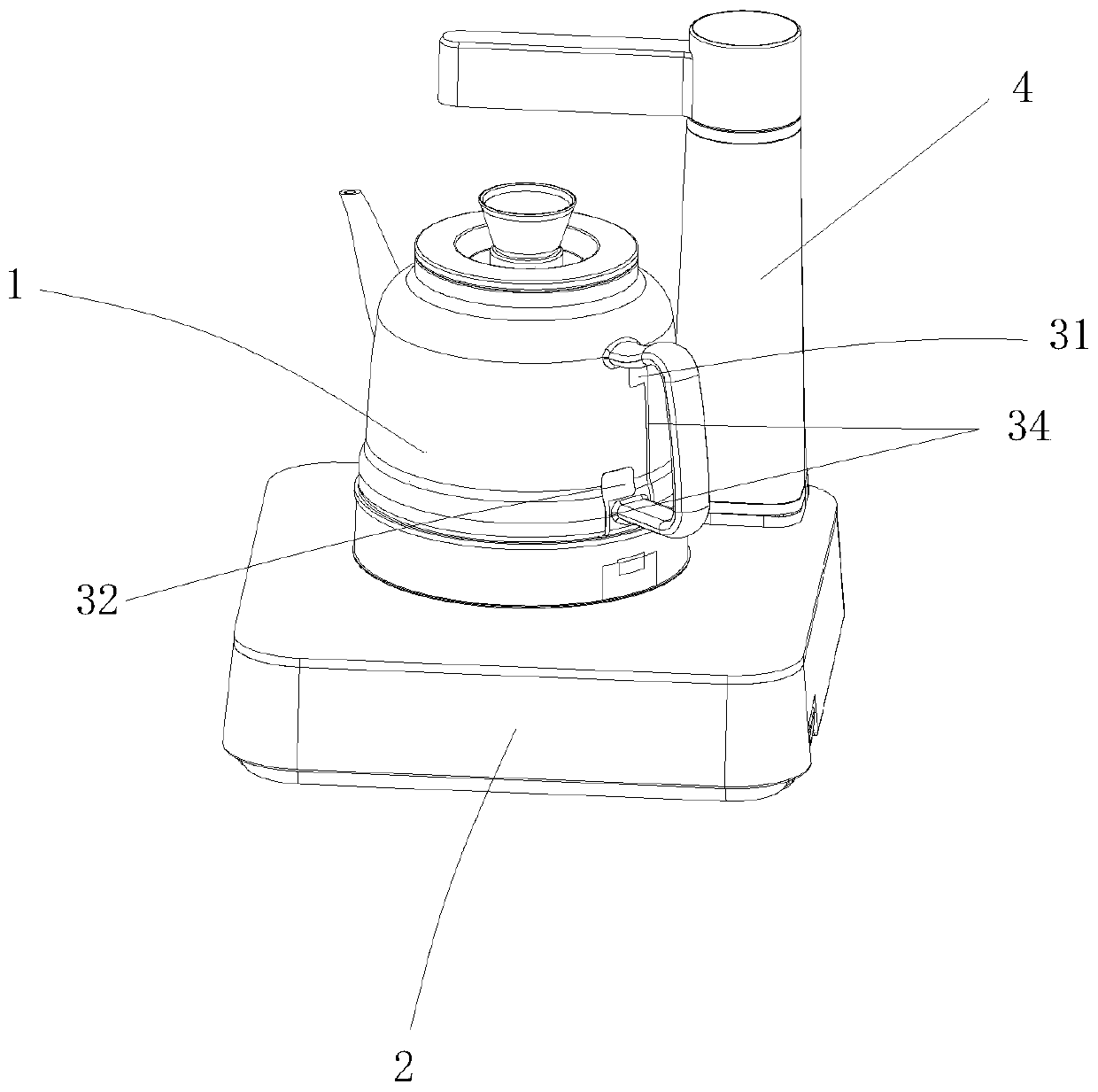

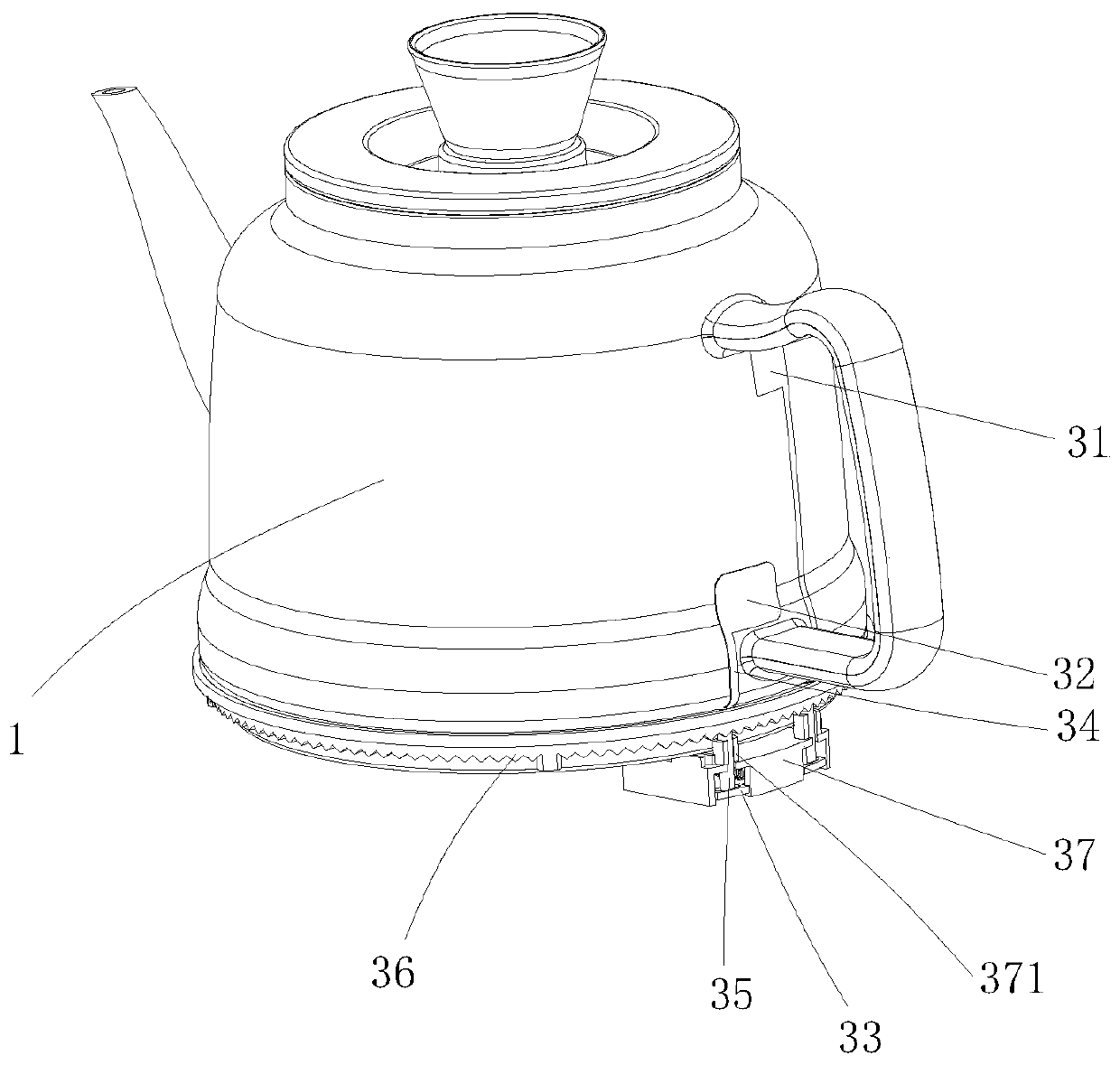

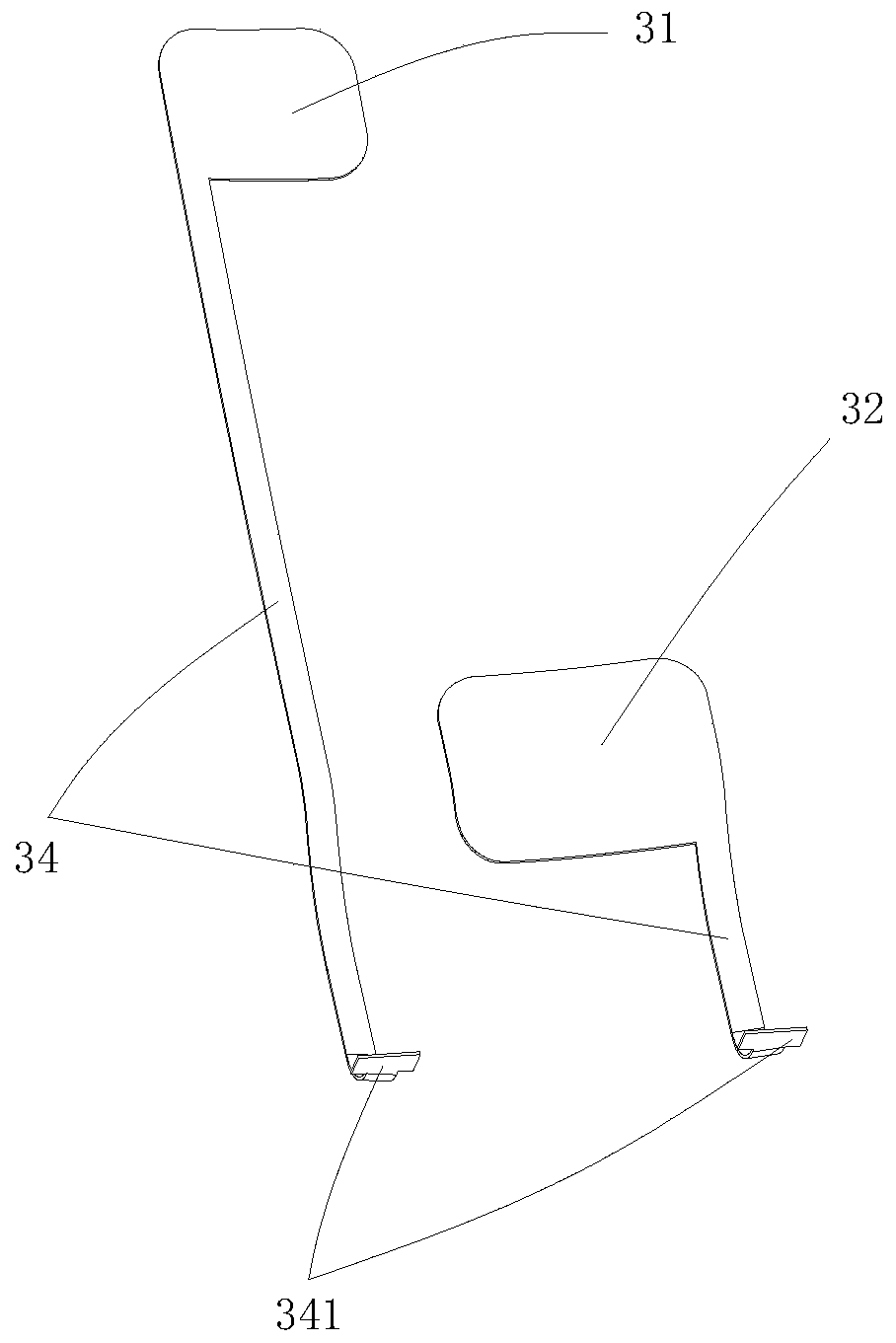

[0029] Such as Figure 1-6As shown, the capacitive water level detection device of the glass kettle disclosed in the present invention may include a high water level sensing disc 31 , a low water level sensing disc 32 and a capacitive detection circuit board 33 . Wherein, the high water level induction disc 31 and the low water level induction disc 32 are respectively fixedly installed (for example, printed or attached) on the outer wall of the glass jug body 1, corresponding to the conductive film at the high water level H and the low water level L. Preferably, the high water level induction plate 31 and the low water level induction plate 32 are installed on the glass kettle body 1 where the handle part is located, so as not to affect the aesthetics of the glass kettle. The capacitance detection circuit board 33 is installed on the chassis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com