Integrated urea solution sensor

A liquid level sensor and integrated technology, which is applied in the field of integrated urea solution sensors, can solve the problems of battery loss, high cost of sensing elements, and easy failure of sealing, and achieve high detection accuracy, low component cost, and low failure rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

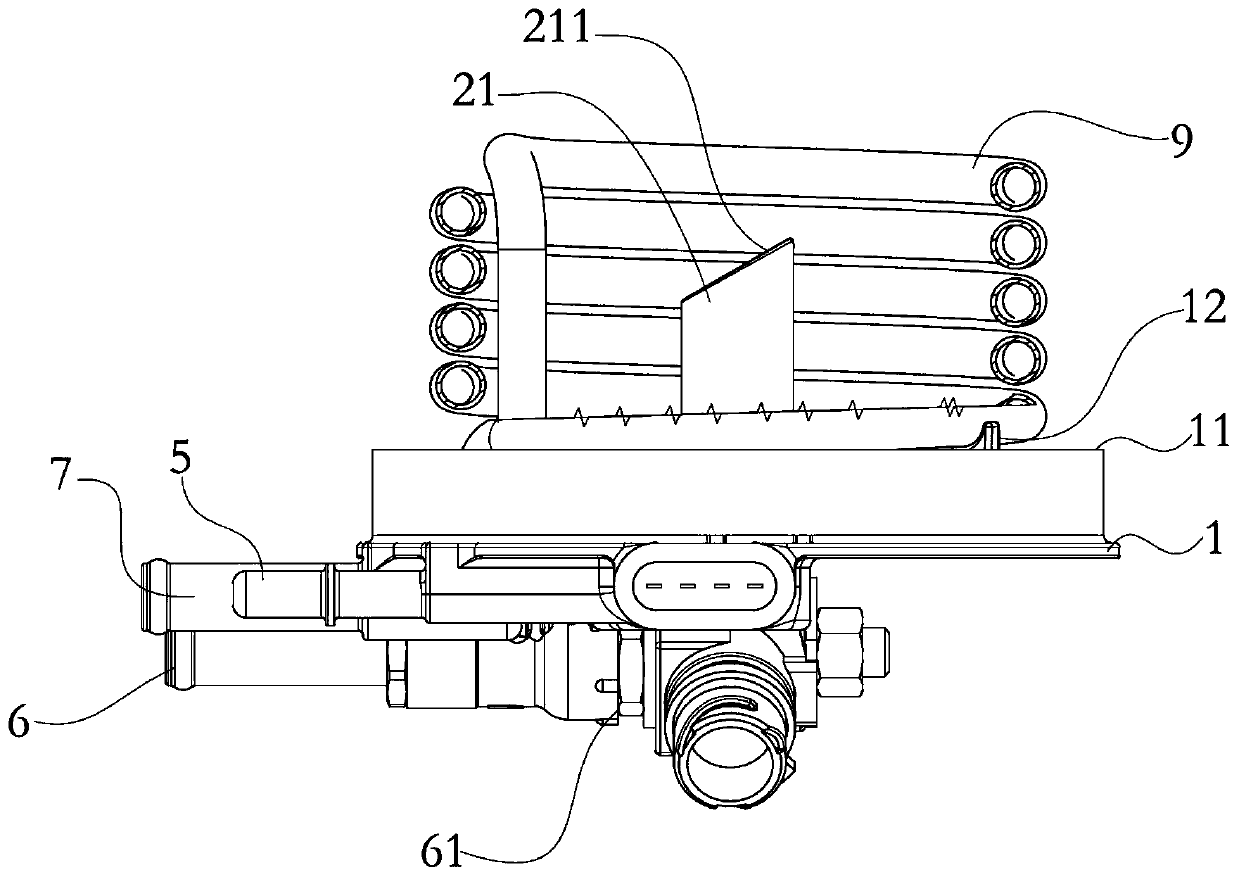

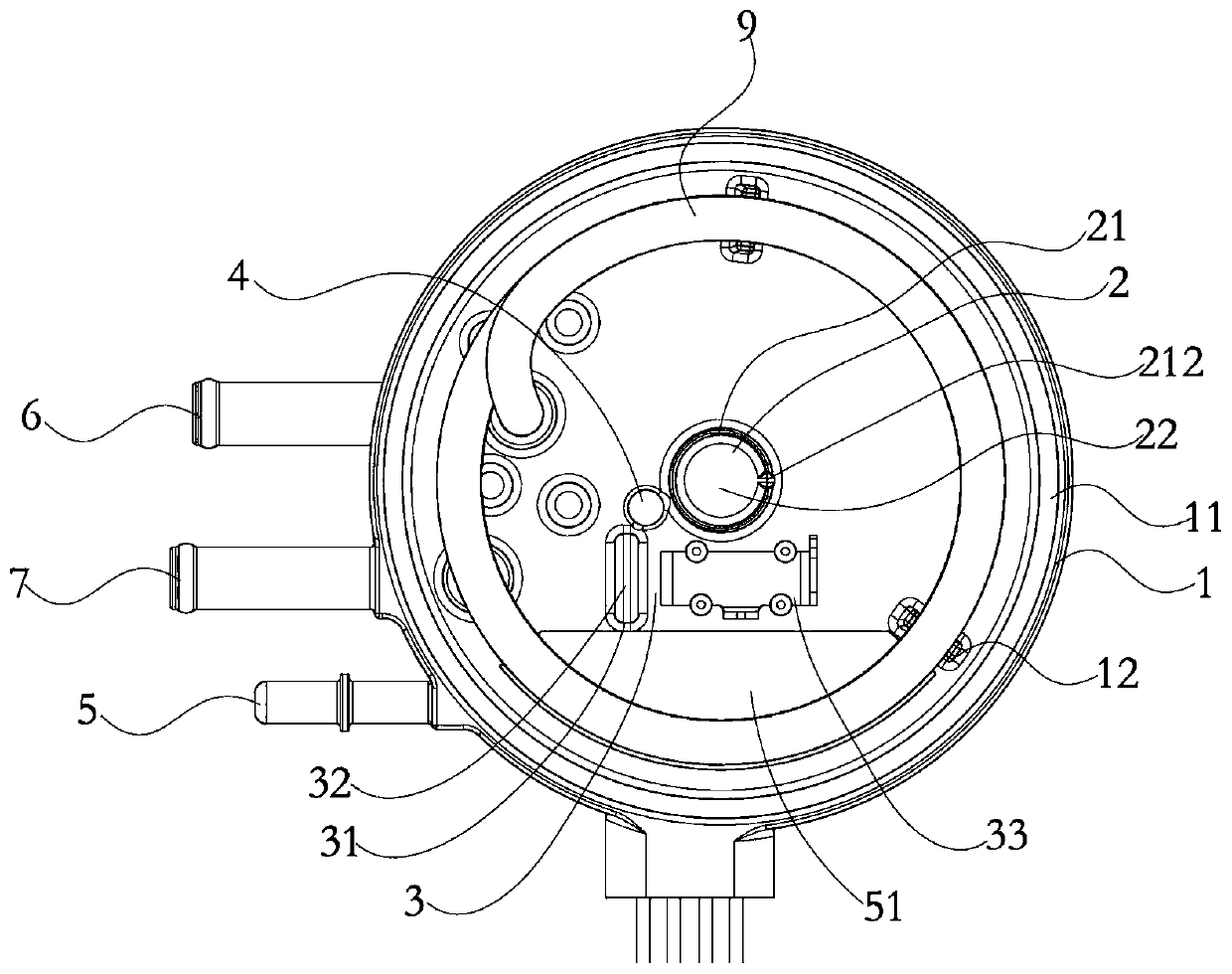

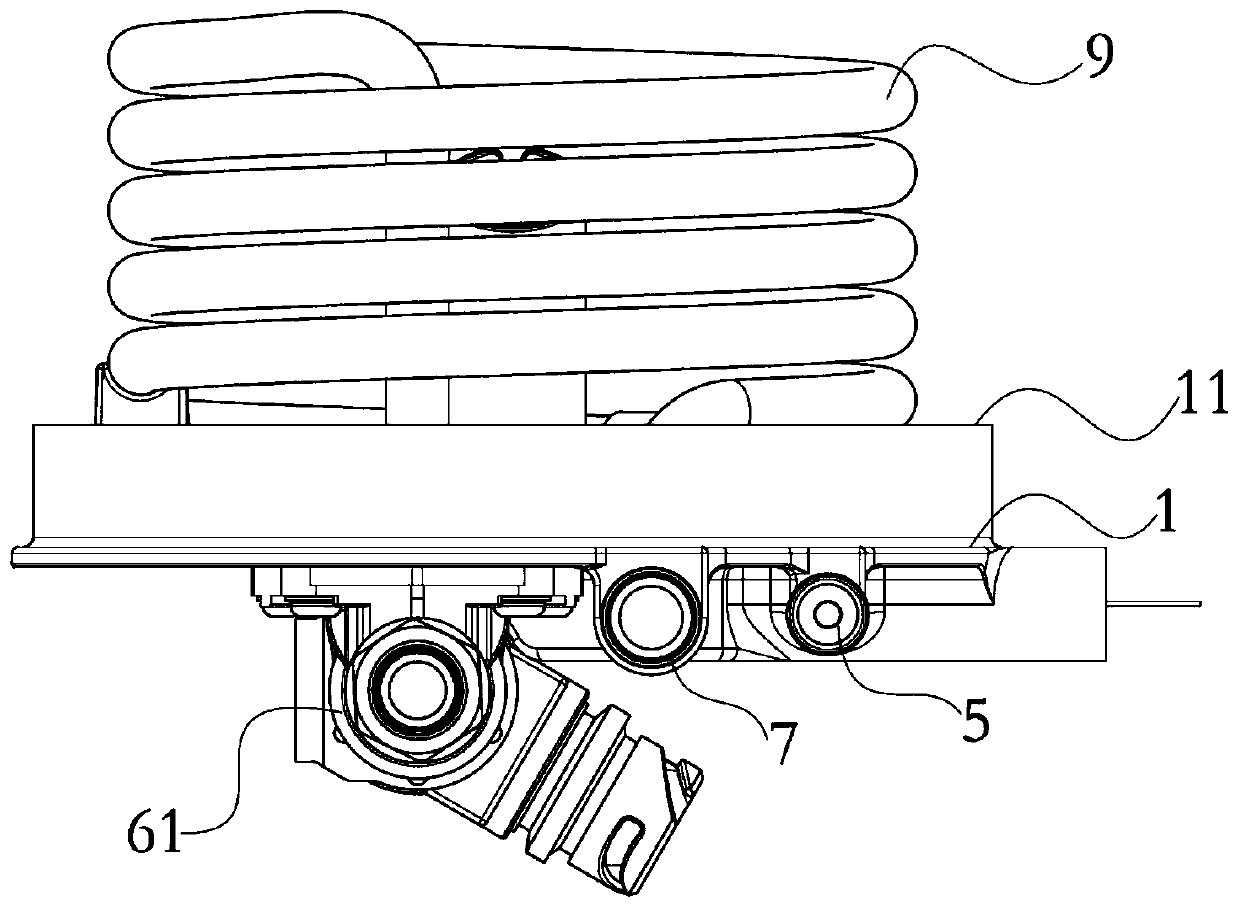

[0048] Attached to the manual below Figure 1-4 , by further describing the specific embodiments of the present invention, the technical solution of the present invention and its beneficial effects will be clearer and more definite.

[0049] An integrated urea solution sensor, the main body of which is a plastic tray 1, a hot-melt interface 11 is provided on the outer circumference of the plastic tray 1, and a liquid level sensor 2, a concentration sensor 3, and a temperature sensor 4 are provided on the plastic tray 1 ;

[0050] The plastic tray 1 is outwardly provided with a suction pipe joint 5, a water inlet pipe joint 6, and a water outlet pipe joint 7;

[0051] A control unit 8 is provided under the plastic tray 1;

[0052] The plastic tray 1 is connected with a heating pipe 9 through the water inlet pipe joint 6, and the other end of the heating pipe 9 is connected to the water outlet pipe joint 7;

[0053] The middle position of the plastic tray 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com