Analysis method of position error of primary mirror block mirror in large-aperture film-based diffractive optical system

A diffractive optics and error analysis technology, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of lack of block mirror impact analysis, difficult to accurately and quantitatively reflect system image quality, deviation, etc., to achieve wide applicability and engineering feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

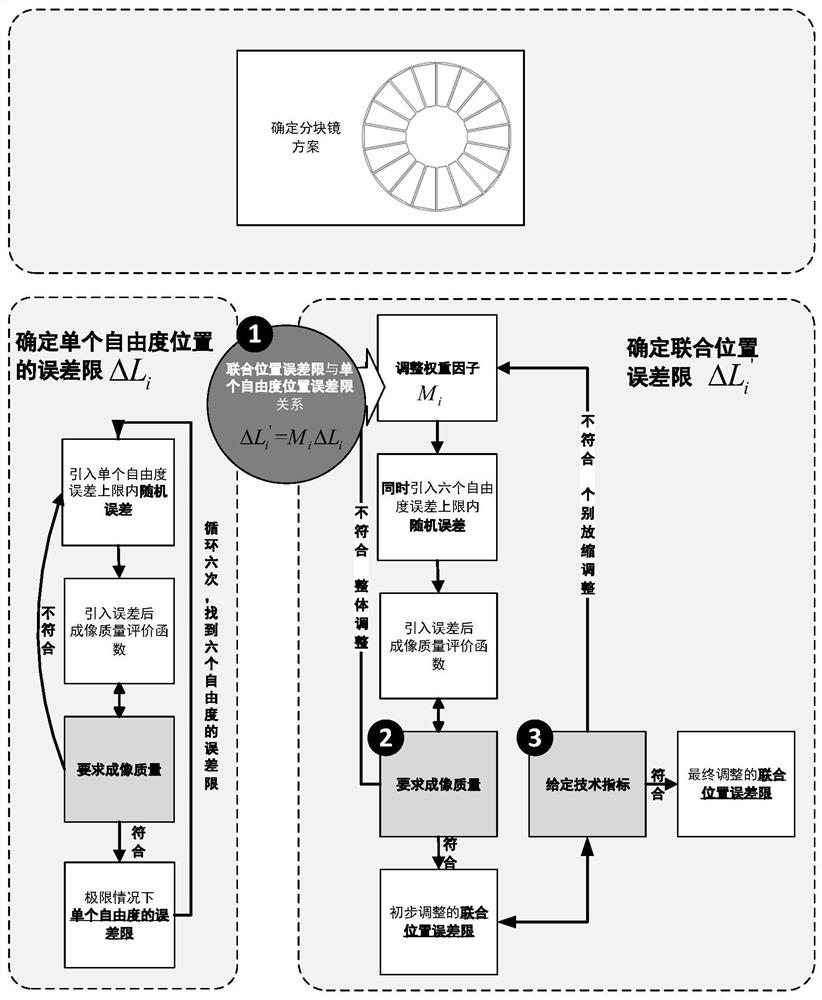

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] The invention provides a large-aperture mirror for the complex shape of the segmented mirror, different numbers of blocks, coupling of various position errors, and image quality degradation related to the structure of the optical system itself, and considering the application in the film-based diffractive optical system. The position error analysis method of the main mirror block mirror of the film-based diffractive optical system can accurately and quantitatively describe the influence of each block mirror position error on the system image quality, and determine the position error limits that meet the system requirements according to the system design indicators .

[0023] like figure 1 Shown, the present invention specifically comprises the following steps:

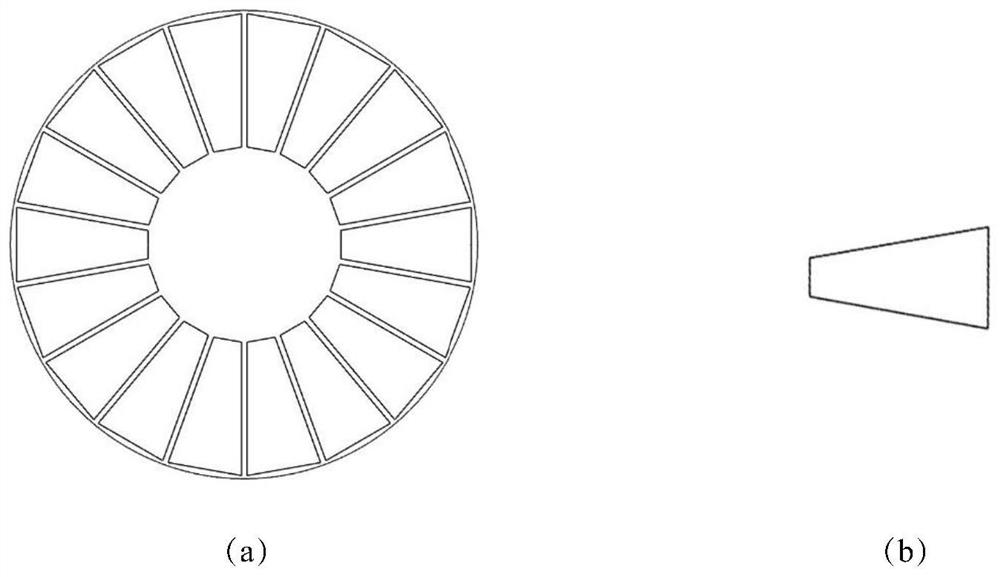

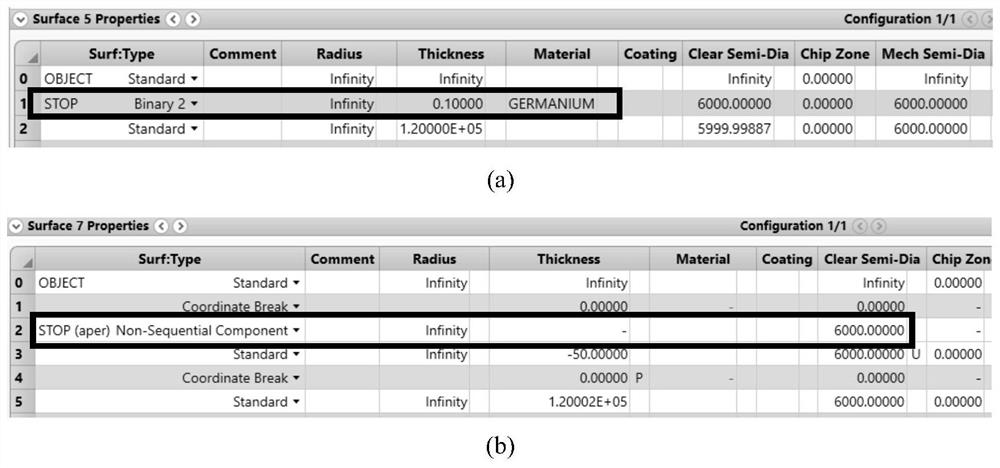

[0024] Step 1. Use ZEMAX optical software to create a block-type film-based diffractiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com