Directional air supply device for textile air conditioner

An air supply device and air-conditioning technology, which is applied in the direction of textiles and papermaking, textile material processing, textile processing machine accessories, etc., can solve the problems of local process environment adjustment, etc., to improve production and processing quality, personalized air supply, temperature control better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

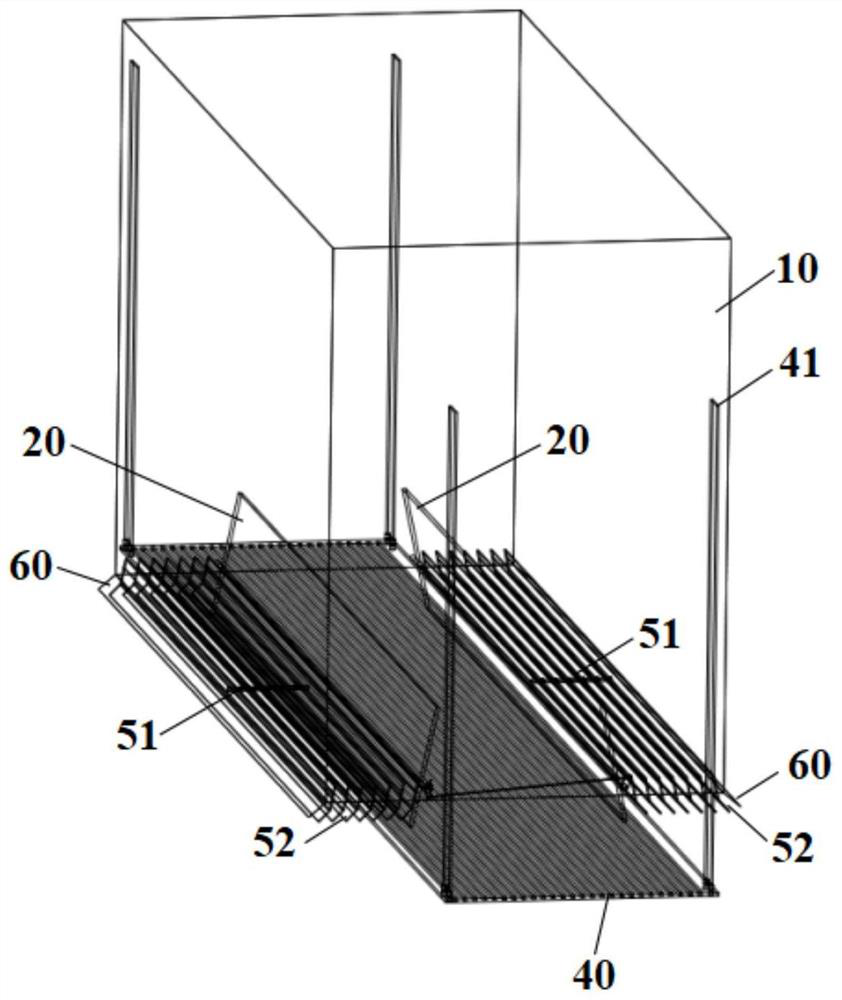

[0039] A kind of textile air conditioner directional air supply device of this embodiment, such as figure 1 As shown, it includes an air supply box 10 arranged below the air supply pipe, and the air supply box 10 communicates with the air supply pipe; the lower end of the air supply box 10 is an air outlet, combined with figure 2 , in the middle of the air outlet of the air supply box 10, a strip-shaped flow equalizer 40 is provided, and the strip-shaped flow equalizer 40 is provided with a strip-shaped vent for sending the air from the air supply box 10 through the strip-shaped vent. To the bottom, the temperature of the factory area is adjusted.

[0040] Preferably, in this embodiment, in order to facilitate the arrangement of the strip-shaped flow equalizer 40 in the middle of the air outlet, combined with figure 2 and Figure 6 , the strip-shaped flow equalizing plate 40 is fixed by the bracket 41, specifically: the bracket 41 is provided with four pieces, and the uppe...

Embodiment 2

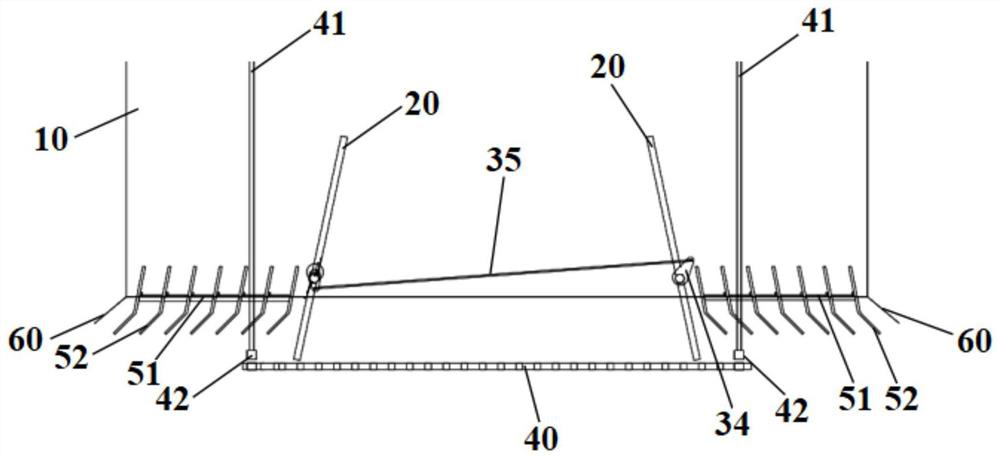

[0060] The directional air supply device of a textile air conditioner in this embodiment is basically the same as in Embodiment 1, the difference is that there are two adjustment mechanisms in this embodiment, such as Figure 5 As shown, the adjustment mechanism includes a connecting piece 32 and a connecting rod 35, wherein the connecting piece 32 is fixedly installed on one end of the round rod 31 protruding from the air supply box 10, and a connecting piece is fixedly installed on the connecting piece 32. 34; combine Figure 4 , both ends of the connecting rod 35 are hinged to a connecting rod piece 34 respectively.

[0061] It is worth noting that the connecting piece 32 in this embodiment is in the shape of a sleeve and is fixedly fitted on the round rod 31; in addition, the orientations of the two link pieces 34 in this embodiment are opposite, as shown in Figure 4 As shown, one of the link pieces 34 faces upwards, and the other link piece 34 faces downwards, so as to ...

Embodiment 3

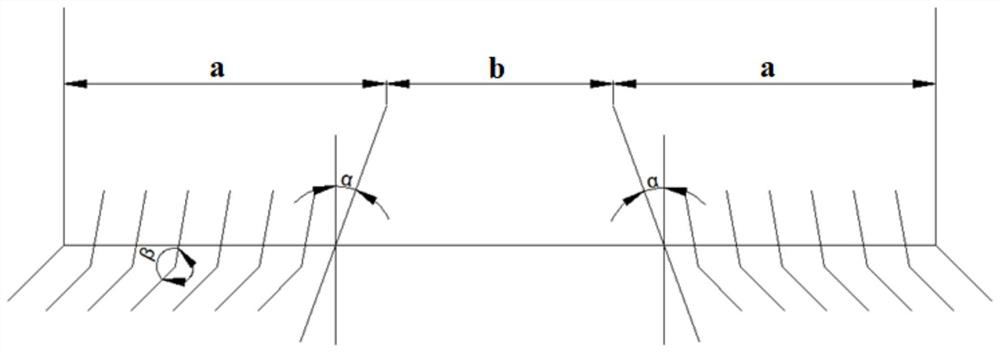

[0064] A kind of textile air-conditioning directional air supply device of this embodiment is basically the same as Embodiment 2, and its difference is: as Figure 7 As shown, the current equalizing guide plate 52 of this embodiment is formed by splicing the upper guide plate 521 and the lower guide plate 522 , preferably, the upper guide plate 521 and the lower guide plate 522 are welded.

[0065] In addition, if image 3 As shown, the angle β between the upper guide plate 521 and the lower guide plate 522 is 120°˜135°. Can be 120°, 125°...130° or 135°.

[0066] It is worth noting that in the actual production process, the airflow organization in the textile workshop is relatively complex, in addition to the air supply and return airflow; there are also airflow caused by the operation of machinery and equipment; heat convection circulation airflow; The airflow and the transverse turbulent airflow formed between the various workshops will affect the production environment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com