Water drainage method for fuel filter

A fuel filter and water drain switch technology, which is applied to machines/engines, liquid fuel feeders, engine components, etc., can solve the problems that the air cannot be ignited, the engine hazards and hazards are not recognized, and the time cost can be avoided. and financial cost, increase time cost and financial cost, and avoid the effect of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

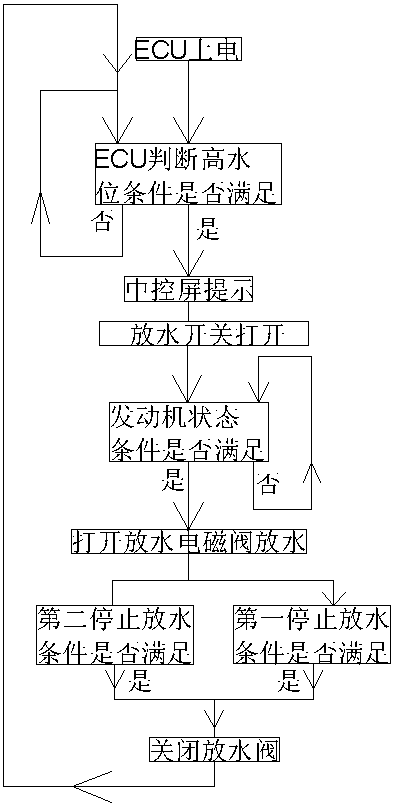

[0038] The invention provides a method for draining water from a fuel filter. The fuel filter has a water collecting cavity, and a water level sensor is arranged in the water collecting cavity. The control panel is located on the center console of the motor vehicle; the bottom of the water collection chamber is connected to a water discharge solenoid valve, which is connected to the on-board ECU through a line, and the on-board ECU stores predetermined high water level information and predetermined low water level information;

[0039] like figure 1 Shown, the present invention carries out according to the following steps:

[0040] The first step is to power on the vehicle ECU;

[0041] The second step is high water level judgment, that is, the on-board ECU judges whether the high water level condition is satisfied, specifically, the on-board ECU obtains the actual water level information detected by the water level sensor, and when the actual water level is higher than or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com