A hydraulic valve for camshaft phaser adjustment

A phaser, camshaft technology, applied in valve devices, machines/engines, non-mechanically actuated valves, etc., to solve problems such as inability to meet emissions, fuel consumption and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

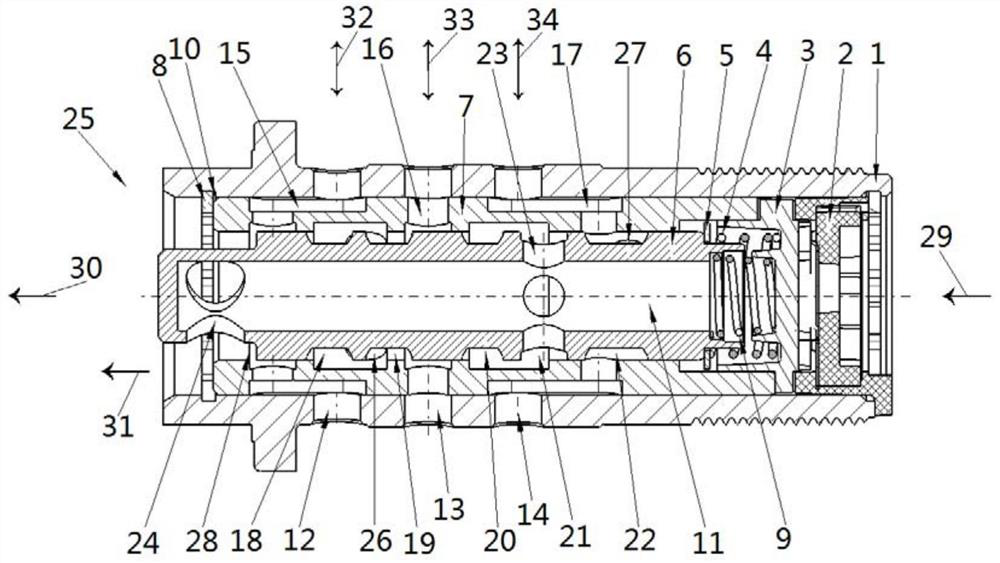

[0020] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

[0021] as attached figure 1 As shown, the present invention is a hydraulic valve for adjusting a camshaft phaser, including a valve body 1, a valve sleeve 7 is set in the valve body 1, a valve core 6 is movably arranged in the valve sleeve 7, and one end of the valve body 1 The hydraulic oil inlet P29 is set, and the other end of the valve body 1 is set with the hydraulic oil outlet T30. Ⅳ21, spool discharge hole Ⅰ23, hydraulic oil outlet T30 are set in a connected structure, valve body oil circuit interface L34, valve sleeve guide chamber Ⅲ17, spool ring groove Ⅳ21, spool discharge hole Ⅰ23, hydraulic oil When the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com