Secondary lining trolley backform mounting device and constructing method thereof

A technology of installation device and jacking device, which is applied to shaft lining, tunnel lining, shaft equipment, etc., can solve the problems of increased engineering volume and construction difficulty, collision of top molds, inconvenient movement, etc., and achieves safe and reliable assembly process. The effect of avoiding mutual collision and reducing the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

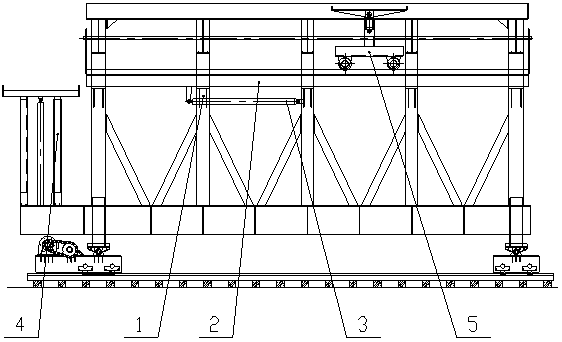

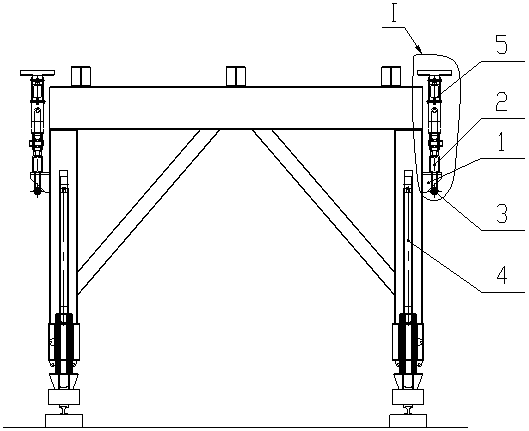

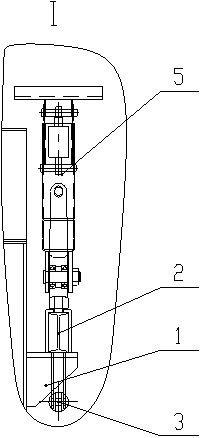

[0037] The following will combine Figure 1-Figure 8 The present invention is described in detail, and the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0038] A roof mold installation device for a two-liner platform, including a sliding groove group 1, a guide rail device 2, a guide rail moving mechanism 3, a jacking device 4, and a transfer device 5. The space where the guide rail device 2 slides longitudinally, the guide rail device 2 can move longitudinally along the sliding groove group 1 under the action of the guide rail moving mechanism 3, and the jacking device 4 is installed on the bottom longitudinal beam of the mast to lift the top mold to the rotary The transfer device 5 can move along the guide rail device 2 and can be raised and lowered, and is used to transfer the top form and move the top form to the installation position and place it on the table beam.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com