Gas-phase antirust oil and preparation method thereof

A gas-phase anti-rust and gas-phase anti-rust agent technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of uneven film formation of gas-phase anti-rust oil, decline in human physical fitness, and insufficient gas-phase performance, and achieve anti-rust performance Strong stability, convenient operation, effective anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Another aspect of the present invention provides a kind of preparation method of vapor phase antirust oil, comprises the following steps:

[0030] (1) Add 70-80 parts of solvent oil into the reaction kettle, start the reaction kettle to stir, and raise the temperature of the solvent oil to 40-60°C;

[0031] (2) After adding 7 to 15 parts of antirust agent to the solvent oil in step (1), after heating to 100 to 110°C, stirring for 30 to 60 minutes at a temperature of 110 to 130°C, and then cooling down to 70 ~80°C;

[0032] (3) After adding 3 to 5 parts of fatty acids to the mixed solution in step (2), stir it for 30 to 60 minutes at a constant temperature of 70 to 80°C;

[0033] (4) Add 4 to 10 parts of film-forming agent to the mixed solution in step (3), and stir it for 30 to 60 minutes at a constant temperature of 70 to 80°C;

[0034] (5) Add 6-12 parts of amine-free gas-phase anti-rust agent to the mixed liquid in step (4), cool down to 50-60 °C and stir for 30-60...

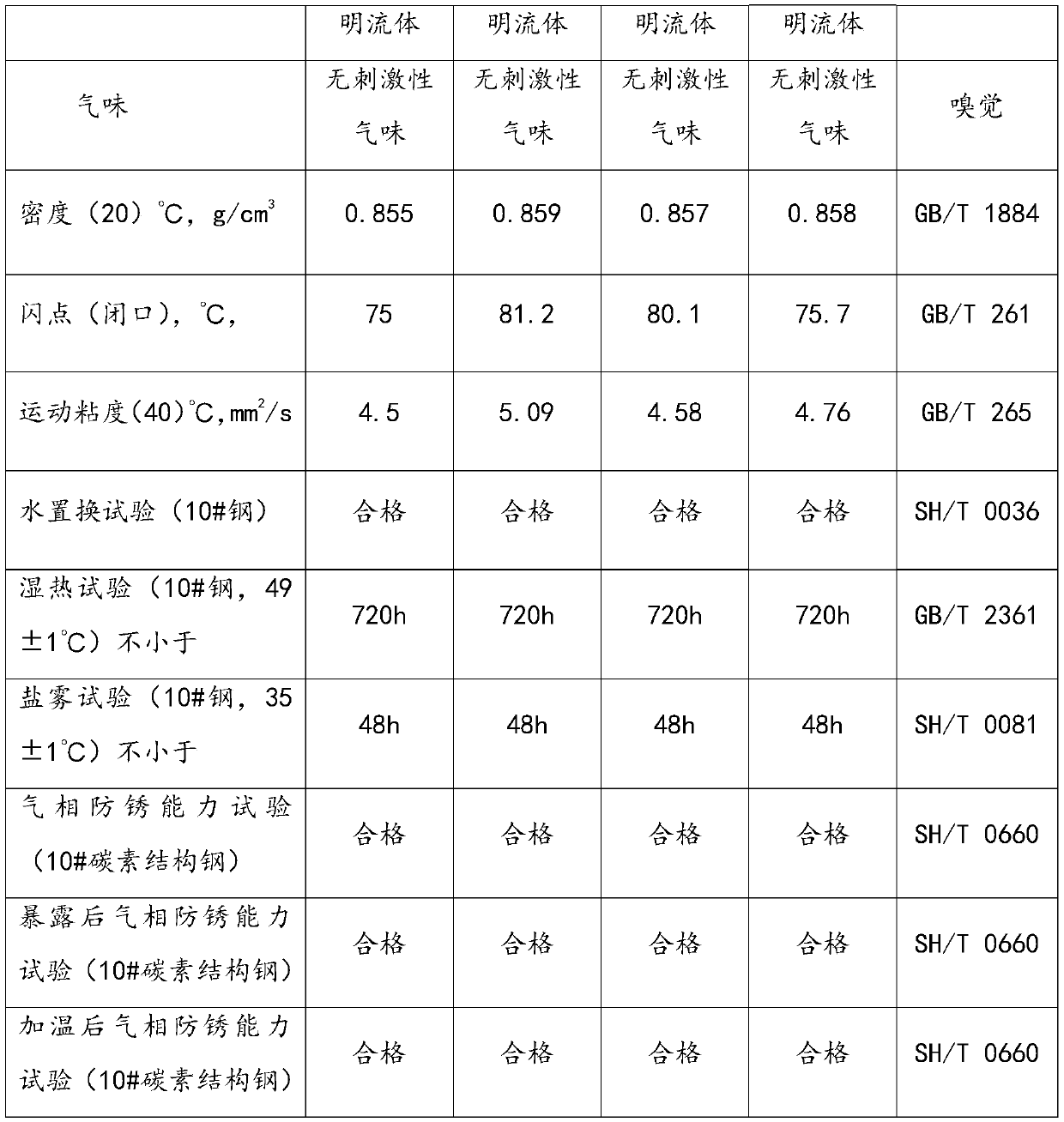

Embodiment 1

[0037] On the one hand, this embodiment provides a gas phase antirust oil, comprising the following components in the following parts by weight:

[0038] 4 parts of sodium petroleum sulfonate, 9 parts of barium dinonyl naphthalene sulfonate, 3 parts of oleic acid, 8 parts of terpene resin, 6 parts of benzotriazole, 20 parts of 25# transformer oil, 50 parts of 3# white oil.

[0039] On the other hand, this embodiment provides a method for preparing a vapor phase antirust oil, comprising the following steps:

[0040] (1) Add 20 parts of 25# transformer oil and 50 parts of 3# white oil into the reactor, start the reactor to stir, and heat up the solvent oil to 50°C;

[0041] (2) After adding 4 parts of sodium petroleum sulfonate and 9 parts of barium dinonylnaphthalene sulfonate to the solvent oil in step (1), after heating to 110 ° C, at a temperature of 110 ° C, after stirring for 50 minutes, Cool down to 80°C;

[0042] (3) After adding 3 parts of oleic acid to the mixed solu...

Embodiment 2

[0046] On the one hand, this embodiment provides a gas phase antirust oil, comprising the following components in the following parts by weight:

[0047] 4 parts of sodium petroleum sulfonate, 6 parts of lanolin magnesium soap, 5 parts of barium dinonylnaphthalene sulfonate, 5 parts of isononanoic acid, 6 parts of butadiene resin, 10 parts of sodium benzoate, 25 parts of 25# transformer oil, 3 parts #50 parts of white oil.

[0048] On the other hand, this embodiment provides a method for preparing a vapor phase antirust oil, comprising the following steps:

[0049] (1) Add 25 parts of 20# transformer oil and 50 parts of 3# white oil into the reactor, start the reactor to stir, and heat up the solvent oil to 40°C;

[0050] (2) After adding 4 parts of sodium petroleum sulfonate, 6 parts of lanolin magnesium soap, and 5 parts of barium dinonylnaphthalene sulfonate to the solvent oil in step (1), after heating to 100 ° C, the temperature of 100 ° C After stirring for 60 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com