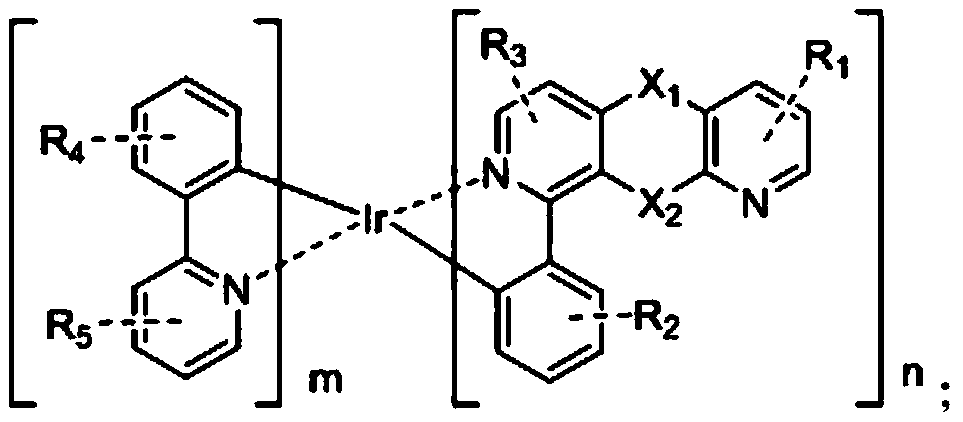

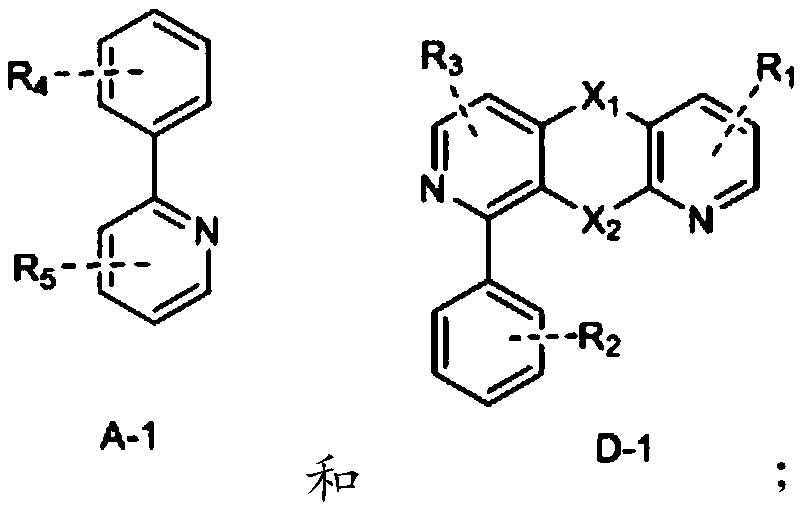

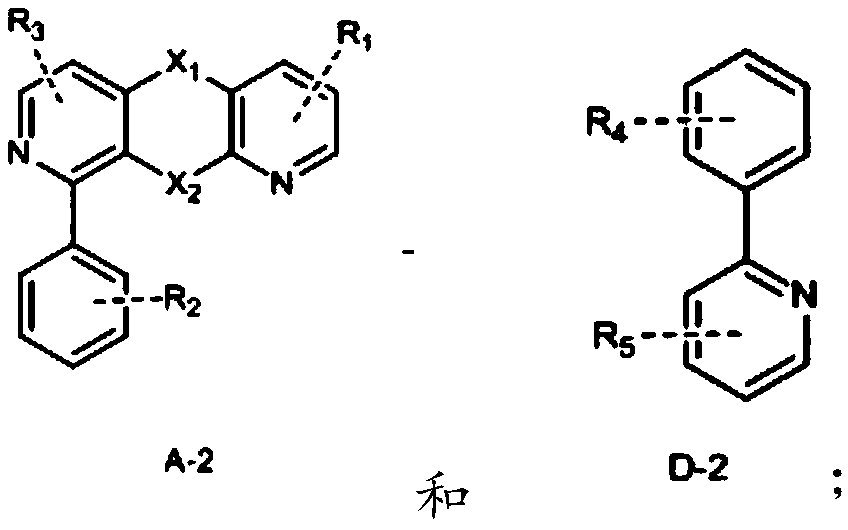

Iridium complex electroluminescent material, preparation method thereof and electroluminescent device thereof

A technology of electroluminescent materials and electrodes, which is applied in the directions of luminescent materials, electro-solid devices, electrical components, etc., to achieve the effect of long service life and improved luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Iridium is combined with electroluminescent material F001, and the structural formula is:

[0089]

[0090] Concrete synthetic steps are as follows:

[0091] (1) Under nitrogen protection system, weigh A-001 (64.4mmol, 10.0g), IrC1 3 ·3H 2 O (21.48mmol, 7.57g) was put into the reaction system, a mixed solvent of 300mL ethylene glycol ether and 100mL pure water was added, refluxed at 130°C for 30h under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, and the precipitate was suction filtered. Rinse and dry in sequence with water, absolute ethanol, and petroleum ether to obtain bridging ligand B-001 (5.8 g, yield 50.4%) as a yellow powder;

[0092] (2) Weigh intermediate B-001 (4.66mmol, 5.0g), add silver trifluoromethanesulfonate (14mmol, 3.6g), then add 100mL of dichloromethane to the system, add 40mL of methanol, under nitrogen protection, Reflux at 55°C for 30 hours, cool to room temperature, and concentrate the fi...

Embodiment 2

[0104] Iridium is combined with electroluminescent material F009, and the structural formula is:

[0105]

[0106] Concrete synthetic steps are as follows:

[0107] (1) Under nitrogen protection system, weigh A-009 (64.43mmol, 10.0g), IrC1 3 ·3H 2 O (21.48mmol, 7.75g) was put into the reaction system, a mixed solvent of 300mL ethylene glycol ether and 100mL pure water was added, refluxed at 132°C for 28h under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, and the precipitate was suction filtered. Rinse and dry sequentially with water, absolute ethanol, and petroleum ether to obtain bridging ligand B-009 (5.8 g, yield 50.4%) as a yellow powder;

[0108] (2) Weigh intermediate B-009 (4.66mmol, 5g), add silver trifluoromethanesulfonate (14mmol, 3.6g), then add dichloromethane 100mL to the system, add methanol 40mL, under nitrogen protection, 58 Refluxed at ℃ for 28 hours, cooled to room temperature, and concentrated the fil...

Embodiment 3

[0120] Iridium is combined with electroluminescent material F019, and the structural formula is:

[0121]

[0122] Concrete synthetic steps are as follows:

[0123] (1) Under the nitrogen protection system, weigh A-019 (59.09mmol, 10g), IrC1 3 ·3H 2 O (19.7mmol, 6.95g) was put into the reaction system, a mixed solvent of 300mL ethylene glycol ether and 100mL purified water was added, refluxed at 135°C for 24h under the protection of nitrogen, and then cooled to room temperature, a precipitate was precipitated, and the precipitate was suction filtered. Rinse and dry in sequence with water, absolute ethanol, and petroleum ether to obtain bridging ligand B-019 (5.4 g, yield 48.6%) as a yellow powder;

[0124] (2) Weigh intermediate B-019 (4.43mmol, 5g), add silver trifluoromethanesulfonate (13.3mmol, 3.42g), then add 90mL of dichloromethane to the system, add 30mL of methanol, under nitrogen protection, Reflux at 60°C for 24 hours, cool to room temperature, and concentrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com