Acid-corrosion-resistant high-strength combined block for furnace lining of circulating fluidized bed boiler

A circulating fluidized bed and combined block technology, applied in the field of boiler lining, can solve the problems of easy cracking, cracks in brick joints, poor acid corrosion resistance and wear resistance, etc., and achieve high boiler utilization rate and obvious economic benefits , high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, the present invention is an acid-corrosion-resistant high-strength composite block for circulating fluidized bed boiler lining, which is characterized in that its main components include 30-50 parts of dense alumina, 5-10 parts of kyanite, and 10-20 parts of burnt gemstone 5-8 parts of activated alumina micropowder, 3-5 parts of zircon powder, 5-10 parts of silicon carbide powder, 3-5 parts of silicon nitride powder, 2-5 parts of pure calcium aluminate cement, wear-resistant steel 1 part of fiber, 0.5-1 part of special additive B, phosphate as a binding additive, of which:

[0042] Dense alumina is the main material, which has the characteristics of wear resistance, corrosion resistance and high strength;

[0043] Kyanite is mainly used to enhance the wear resistance of composite blocks;

[0044] Zircon powder is mainly used to enhance the thermal shock resistance of the composite block, which can make the composite block continue to expand in the high te...

Embodiment 2

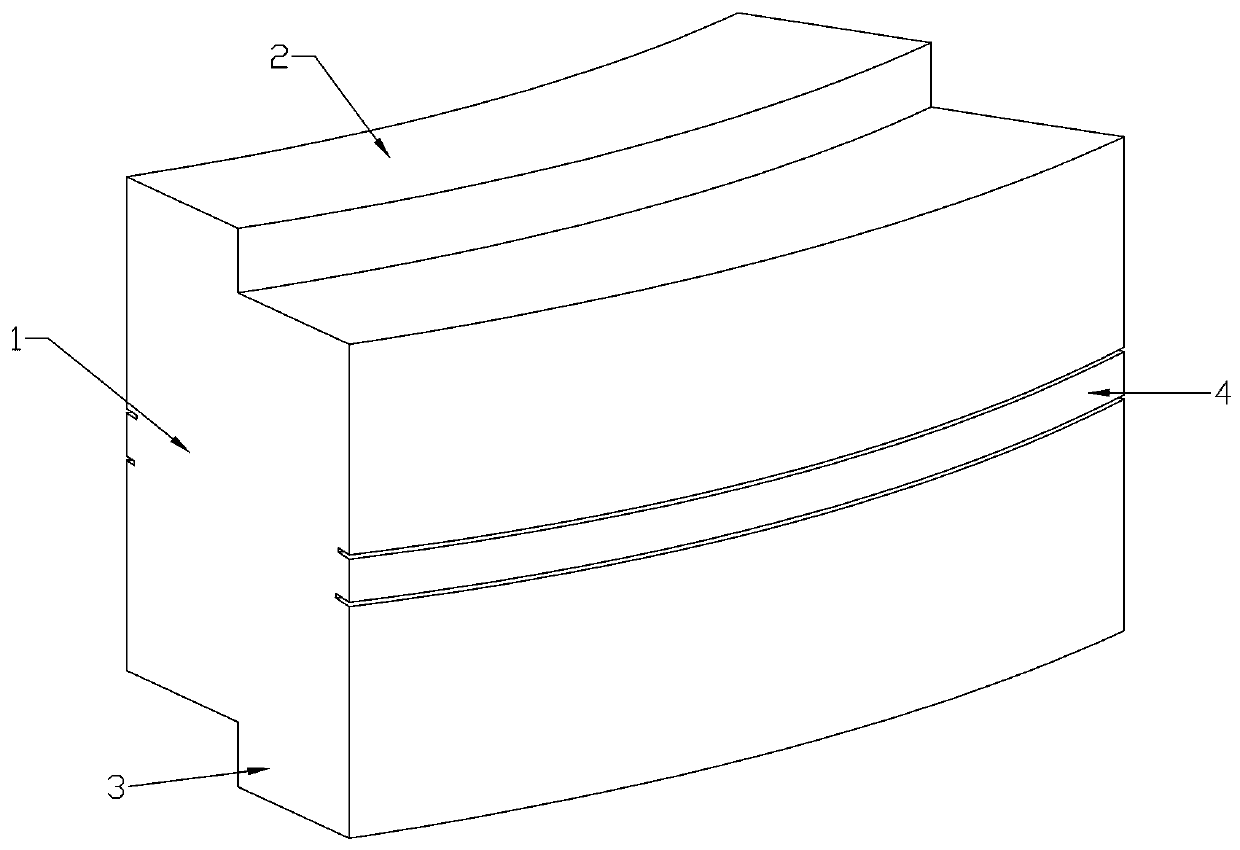

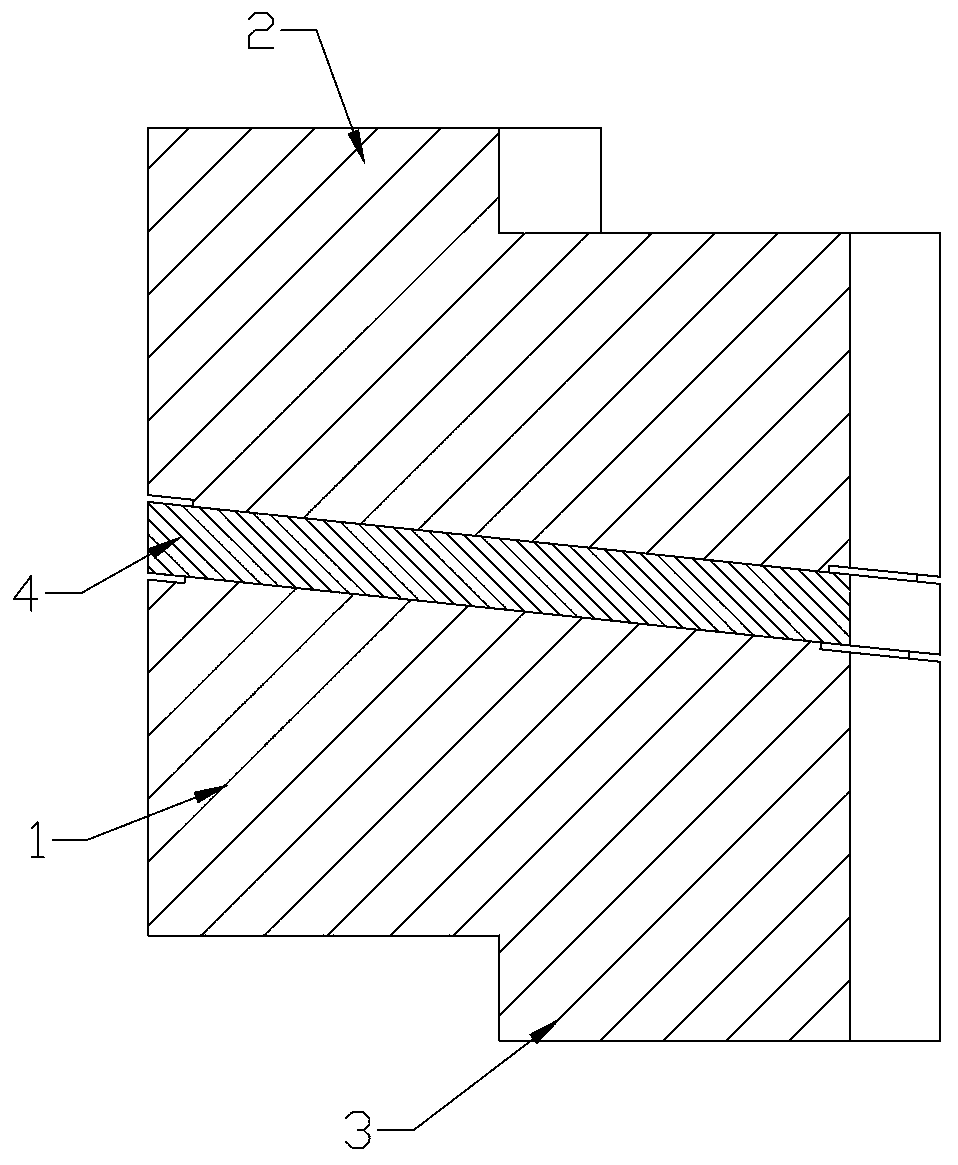

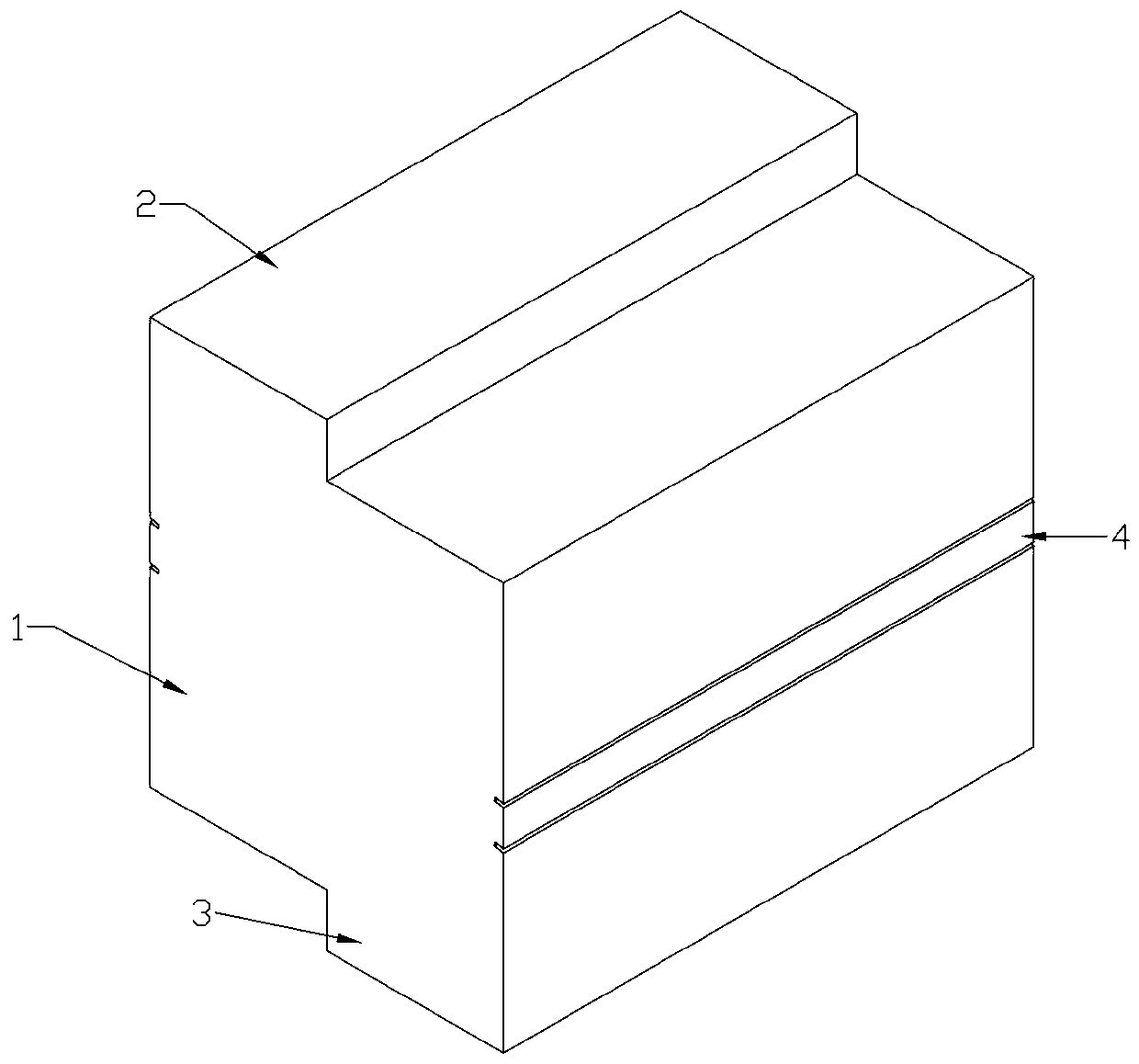

[0058] Embodiment two, on the basis of embodiment one, refer to image 3 , Figure 4, the boiler lining is mainly composed of demolition blocks 1, the structure of the demolition block 1 is a cubic brick structure, the upper end of the demolition block 1 is fixedly connected with the upper card body 2 at the inner side of the boiler, and the lower end of the demolition block 1 faces One end of the side wall of the boiler is fixedly connected with the lower card body 3, and the end surface area of the long card body and the lower card body 3 is half of the end surface area of the cubic part of the demolition block 1, so that it is easy to assemble, and each demolition block 1 is fastened up and down to form a boiler lining When assembling, the upper card body 2 of each demolition block 1 and the lower card body 3 of the adjacent demolition block 1 are fastened and spliced, that is, each demolition block 1 is longitudinally assembled when assembling, and the upper card body ...

Embodiment 3

[0060] The third embodiment, on the basis of the second embodiment, also includes a conventional block 5, the external shape of the conventional block 5 is the same as that of the demolition block 1, and the conventional block 5 does not contain a mosaic 4, and the conventional block 5 can be combined with The conventional blocks 5 are combined with each other, and can also be combined with the demolition block 1, the only difference is that the mosaic 4 is arranged inside;

[0061] The assembly form of the conventional block 5 and the demolition block 1 is that two conventional blocks 5 are arranged between the two demolition blocks 1. Because the manufacturing process of the demolition block 1 is relatively complicated and the cost is relatively high, this setting can effectively control the cost, and can also It effectively guarantees that it can be effectively dismantled during maintenance and dismantling, taking into account both construction cost and maintenance cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com