Bioreactor plant

A bioreactor and biomass technology, applied in the field of biotechnology research, can solve the problems of not being able to provide high-quality biomass mixing, affecting the processing quality of raw materials, and not ensuring the temperature stability of biomass, so as to improve productivity and quality , Improve production capacity and processing quality, improve productivity and its quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

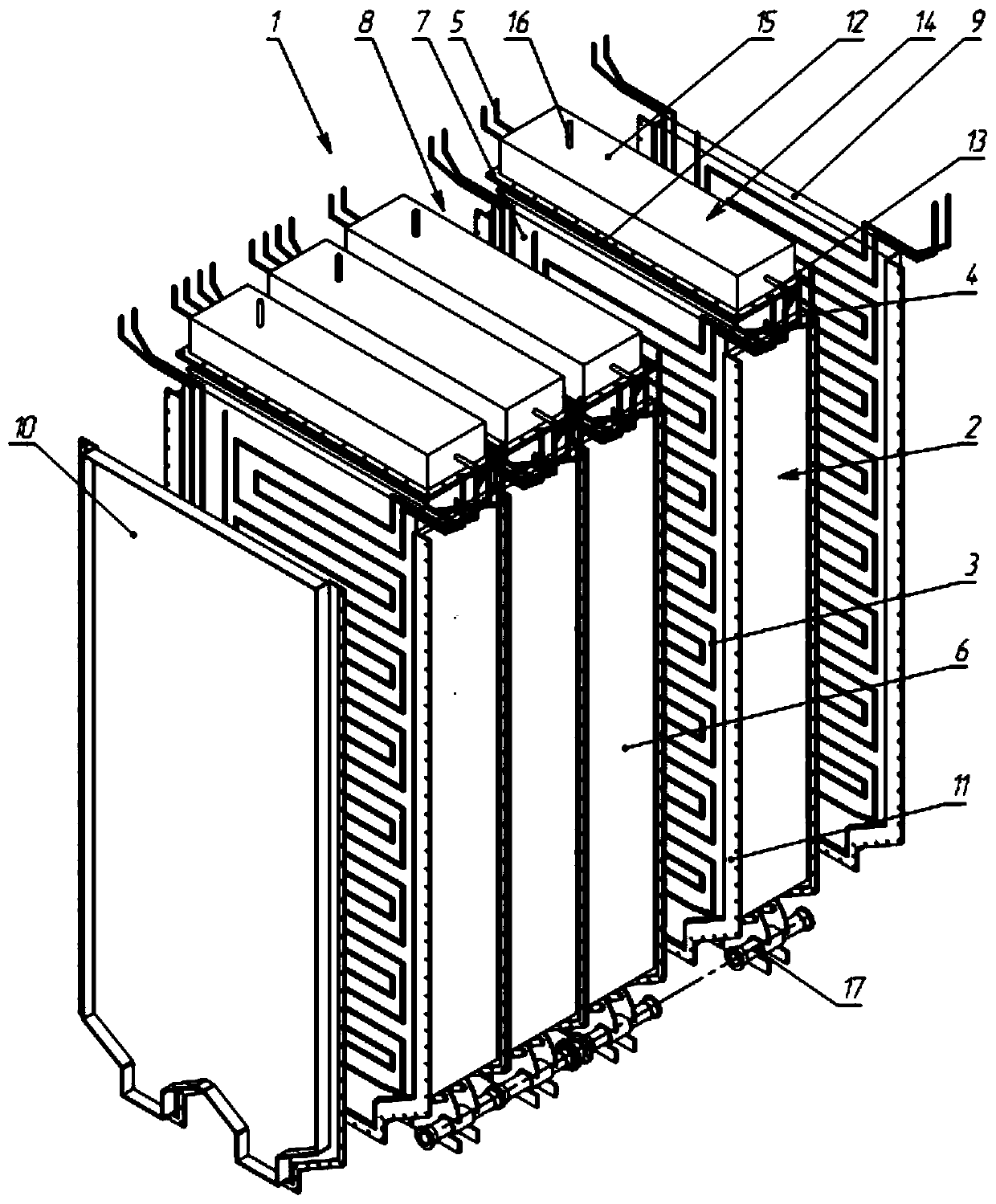

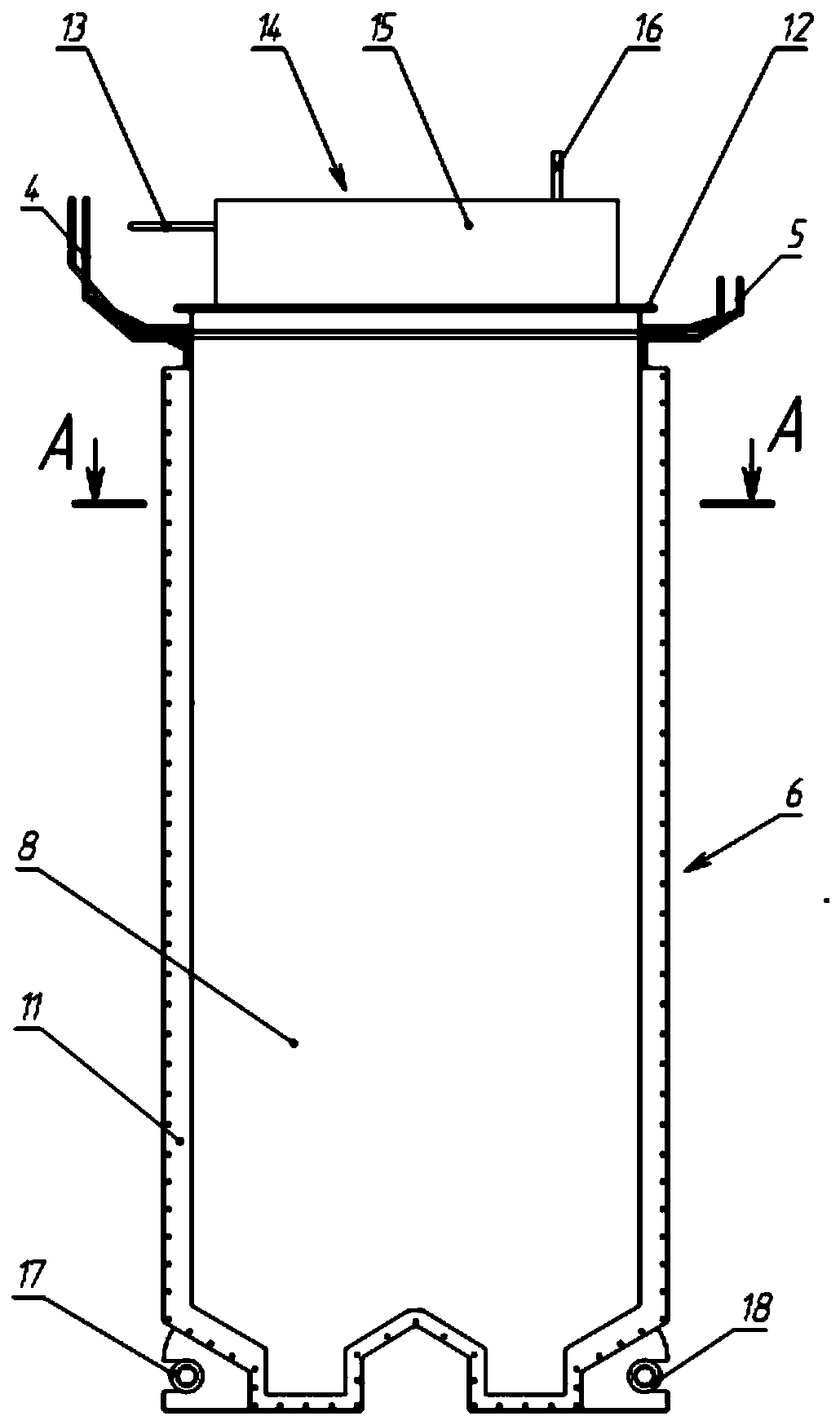

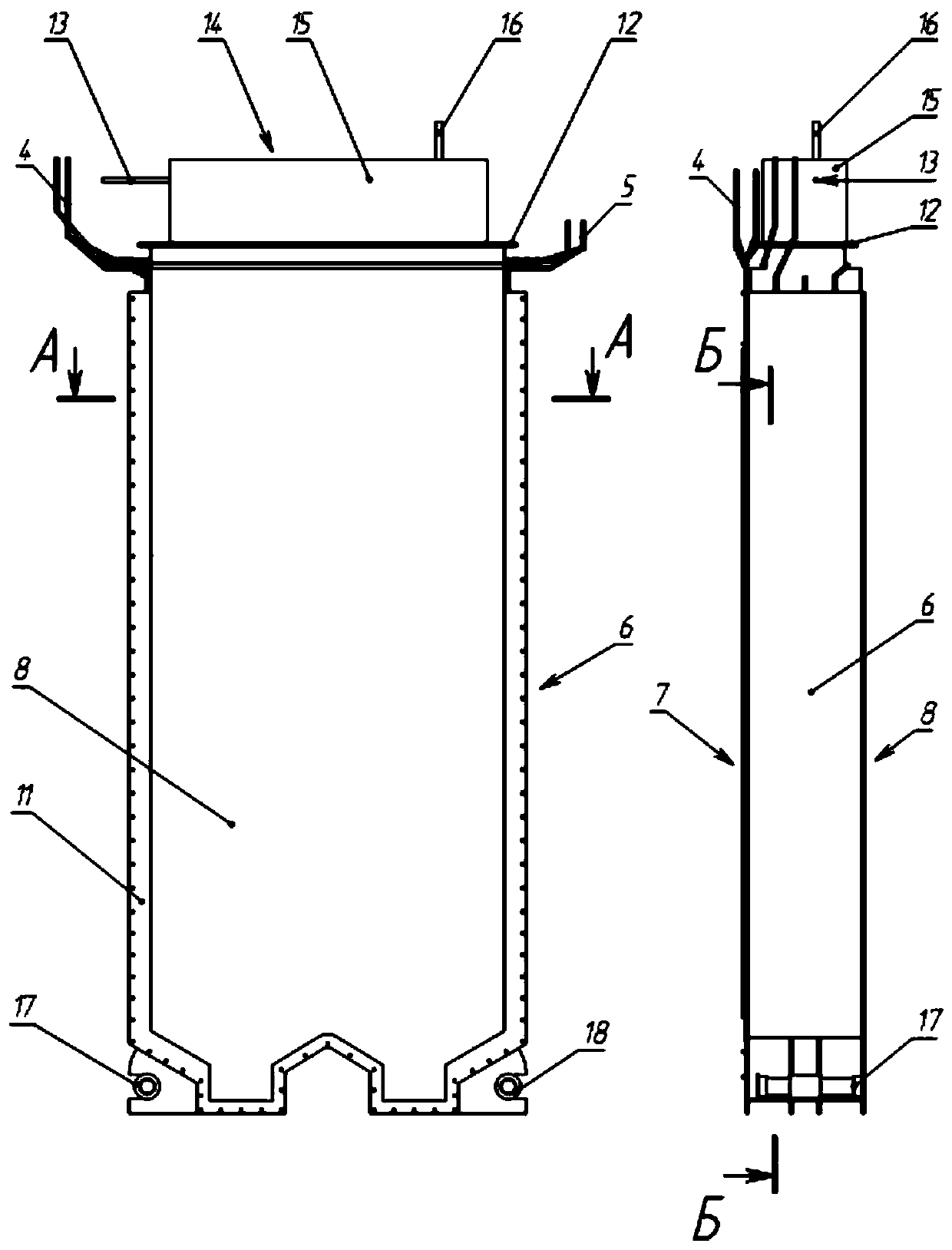

[0042] The preferred embodiments of the present invention will be further described below in conjunction with the drawings. The drawings and embodiments are only explanations of the present invention, and the practical technical solutions of the present invention are not limited to the contents described in the drawings and embodiments.

[0043] A bioreactor apparatus consisting of a group of parallel bioreactors 2 of the same type, each equipped with an outlet pipe, a cover with an inlet pipe, an air outlet pipe and a biofilter 24 filled with microorganisms , a distribution unit node connected to the inlet pipe 14 is provided on the cover of each of the bioreactors 2, and each of the bioreactor housings 15 is a vertically oriented cuboid with a heating circuit pipeline The function of automatically adjusting water heating, the pipeline is located on a side wall of the bioreactor main body, and has a thermal insulation structure; the bioreactor housing 15 is sequentially connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com