Method for relieving membrane pollution of aerobic membrane bioreactor

A membrane bioreactor and membrane fouling technology, applied in chemical instruments and methods, biological water/sewage treatment, sustainable biological treatment, etc., to achieve the effect of alleviating membrane fouling, reducing operating costs, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

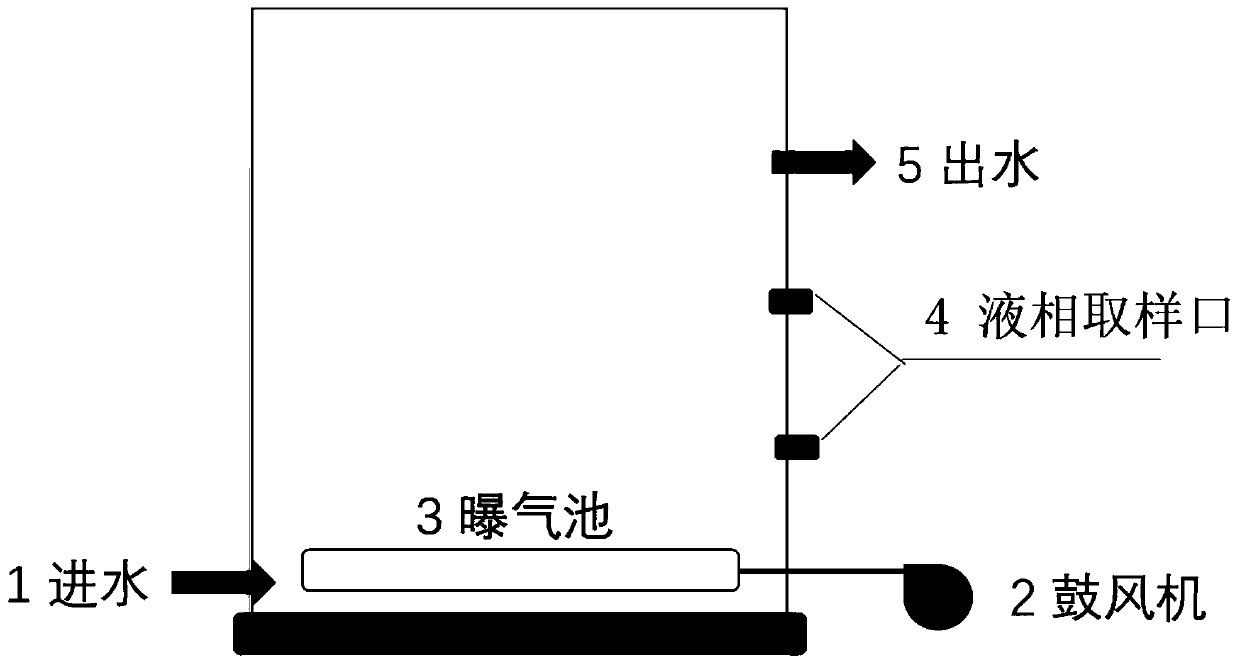

Examples

Embodiment 1

[0026] Take 350mL of aerobic activated sludge inoculum. The sludge is taken from the aerobic section activated sludge of Fuzhou Jinshan Wastewater Treatment Plant. The activated sludge is passed through a 300-mesh iron sieve to remove non-biological impurities such as fine sand, and then 500mL of Inorganic salt medium (conventional medium, pH value is 7.2-7.8, its composition is NaNO 3 550mg / L; NaHCO 3 500mg / L; KH 2 PO 4 60mg / L; Na 2 SO 4 20mg / L; CaCl 2 10mg / L; MgSO 4 ·7H 2 O 7.0mg / L; FeSO 4 ·7H 2 O 15mg / L; H 3 BO 3 0.4mg / L; ZnSO 4 ·7H 2 O 1.8mg / L; CuSO 4 ·5H 2 O 0.7mg / L; MnCl 2 4H 2 O 0.6mg / L; NaMoO 4 2H 2 O 0.6mg / L; CoCl 2 ·6H 2 O 0.8mg / L; NiCl 2 ·6H 2 O 0.6mg / L) suspended sludge, vortex oscillation to mix evenly; set the centrifuge at 9000rpm, centrifuge for 4 minutes, remove the supernatant; repeat the above steps 3-5 times to remove residual dissolved organic matter in the sludge.

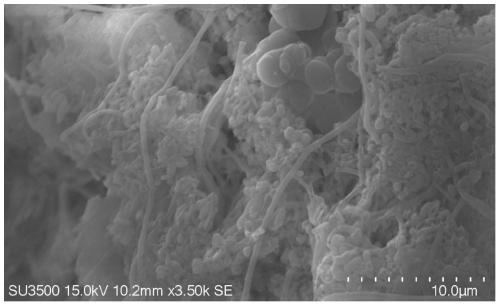

[0027] Afterwards, 350 mL of activated sludge after cleaning ...

Embodiment 2

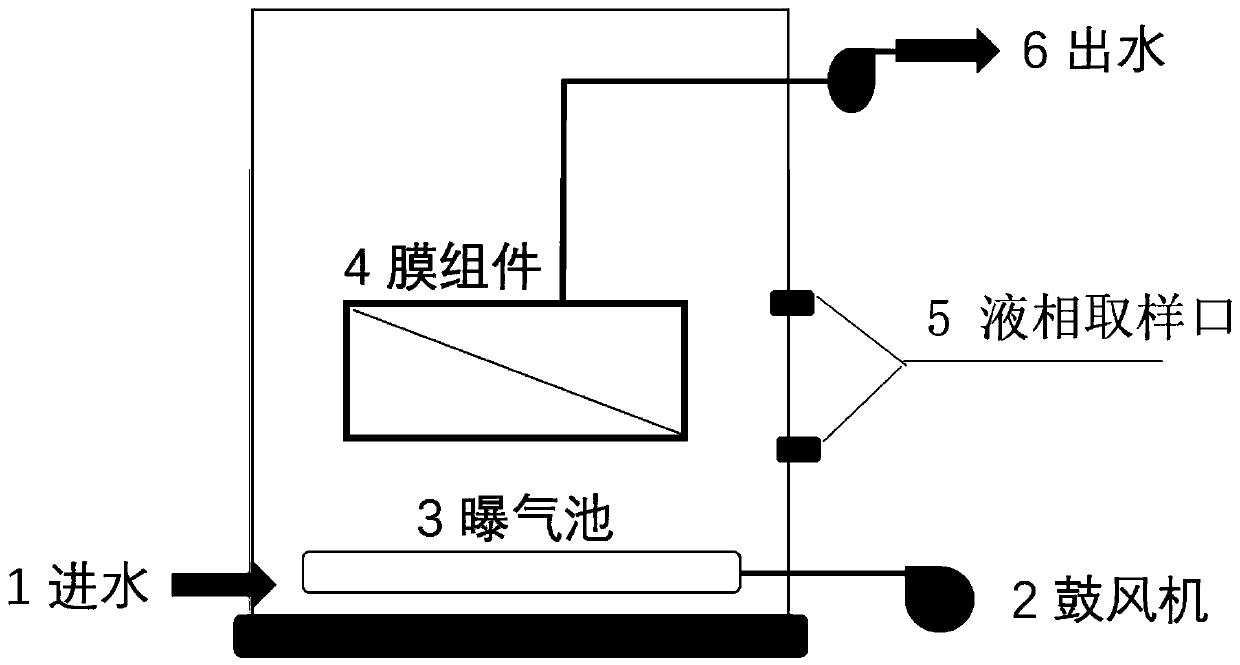

[0031] In an aerobic membrane bioreactor ( image 3 , volume is 10L), inoculate this aerobic polysaccharide hydrolysis flora, inoculum size is 125mL / L, adopt blower aeration, maintain dissolved oxygen (DO) at 5mg / L. Under the condition of a temperature of 26°C, it was operated continuously for 100 days with domestic sewage (CODcr 380mg / L) as the substrate, and the water inflow rate was 8.5L / day. Other operations were the same as in Example 1. After testing, the COD of the effluent is lower than 20mg / L, and the membrane fouling has been greatly improved, the membrane flux is stable, and the effluent rate is 8.5L / day. Moreover, the effluent basically meets the requirements of Grade A in the Discharge Standard of Pollutants for Urban Sewage Treatment Plants (GB 18918-2002).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com