Pouch with spout

A technology of flow outlet and flow path control, applied in the direction of bags, sacks, containers, etc., can solve the problems of the risk of overturning the original product, trouble for users, etc., and achieve the effect of improving the interruption and realizing the temporary stop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

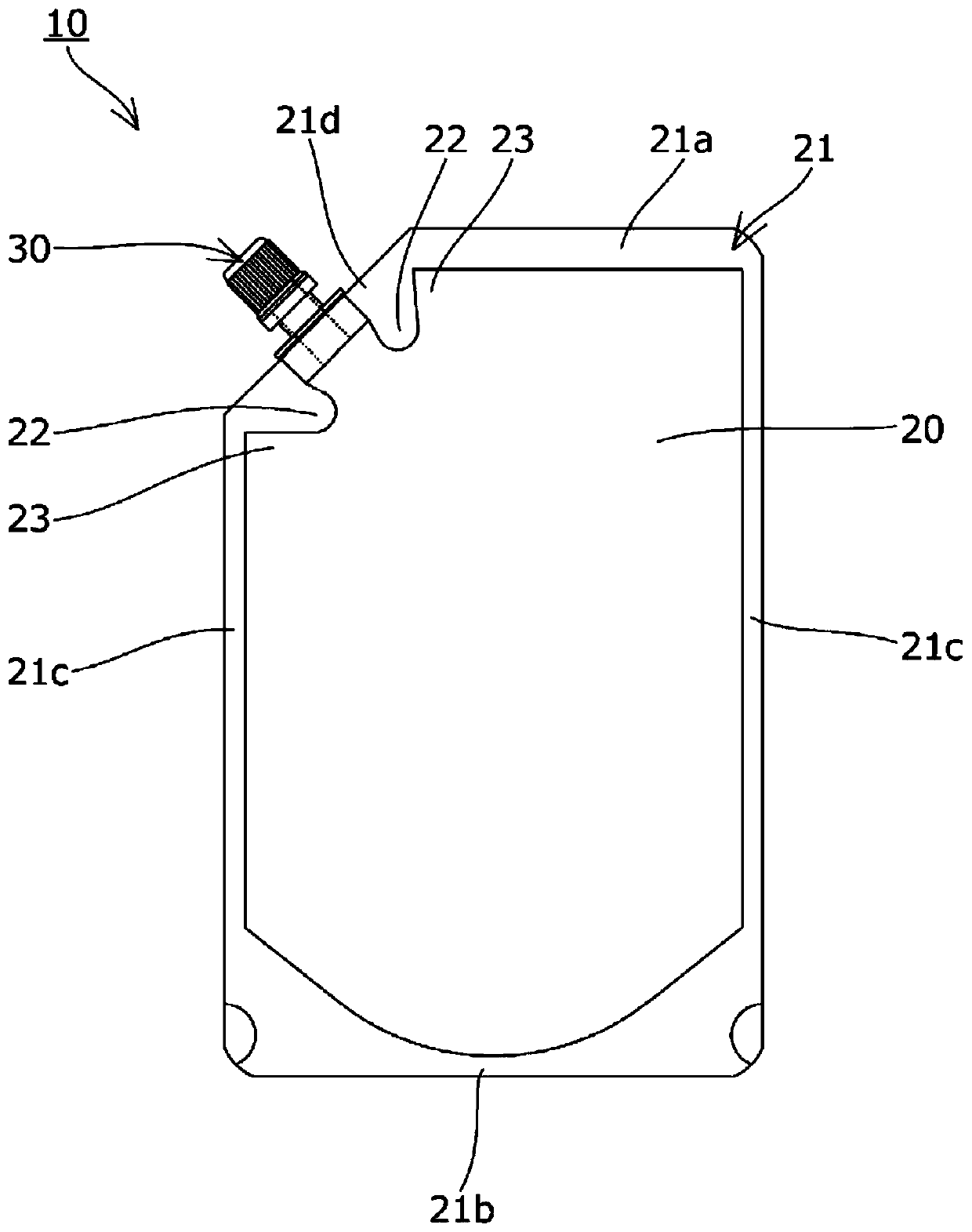

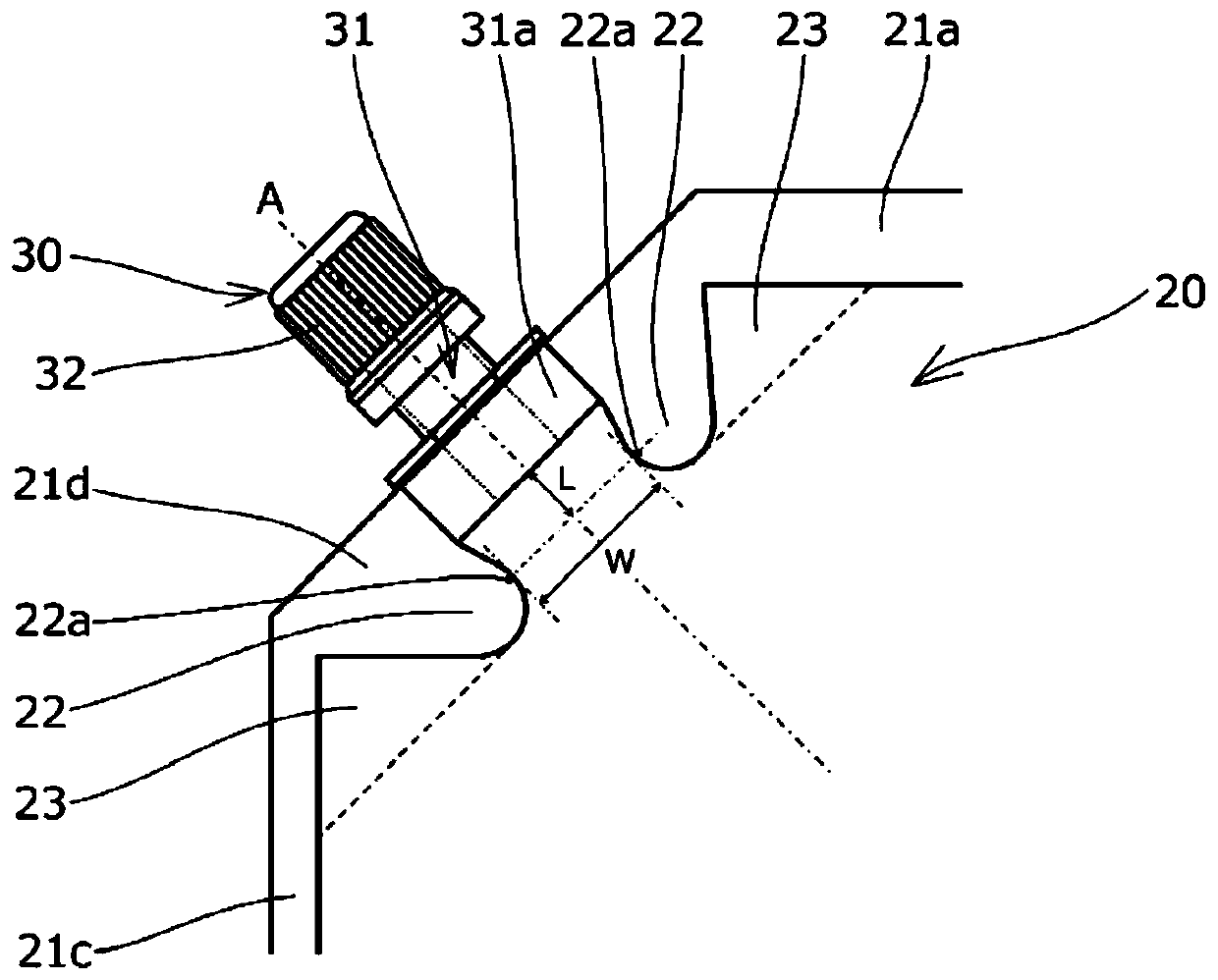

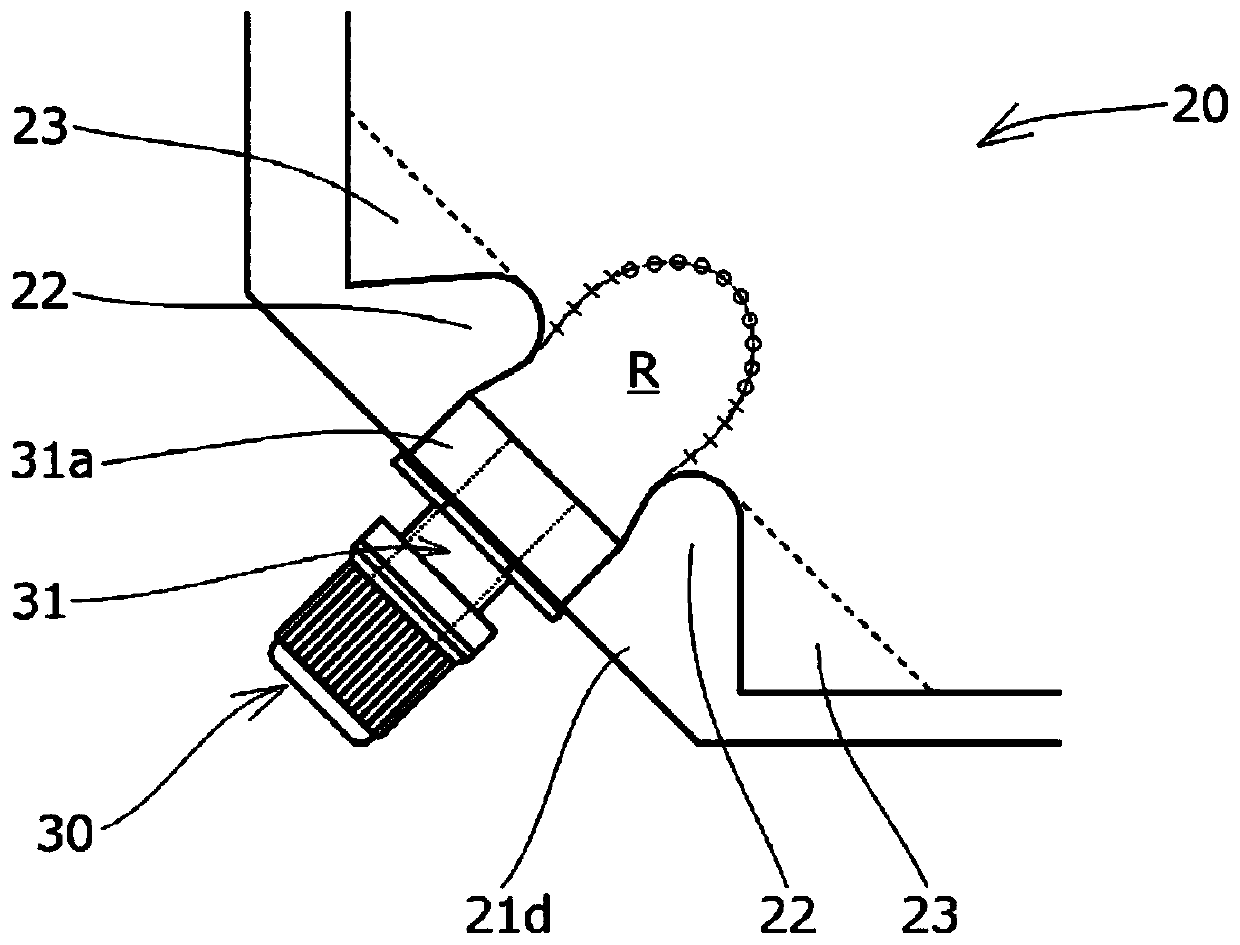

[0060] Next, the spout-equipped bag 10 according to the first embodiment of the present invention will be described based on the drawings.

[0061] Such as figure 1 As shown, the bag 10 with a spout is constituted by forming a pouch body 20 formed in a bag shape by forming an outer edge sealing portion 21 obtained by thermally welding the outer edges of overlapping films, and attaching a spout to function as a spout. Functional outflow port 30, thereby containing content liquids such as detergent and shampoo.

[0062] Below, based on Figure 1 ~ Figure 3 The respective constituent elements of the spout-equipped bag 10 will be described.

[0063] First, the bottom part is thermally welded between the two main parts by using the two main parts on the front and back sides and the bottom part bent into an inverted V shape, which are made of laminated films, such as figure 1 As shown, the bag main body 20 has an overall shape as a stand-up bag having: an upper edge; a lower edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com