A scanning type textile digital printing equipment

A digital printing and scanning technology, applied in the direction of printing, printing devices, etc., can solve the problems of poor flatness of manual cloth glue, easy to be affected by the environment, and etc., to improve work efficiency, improve printing quality, scientific and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075]The present invention and its beneficial technical effects will be further described below in conjunction with the drawings and preferred embodiments.

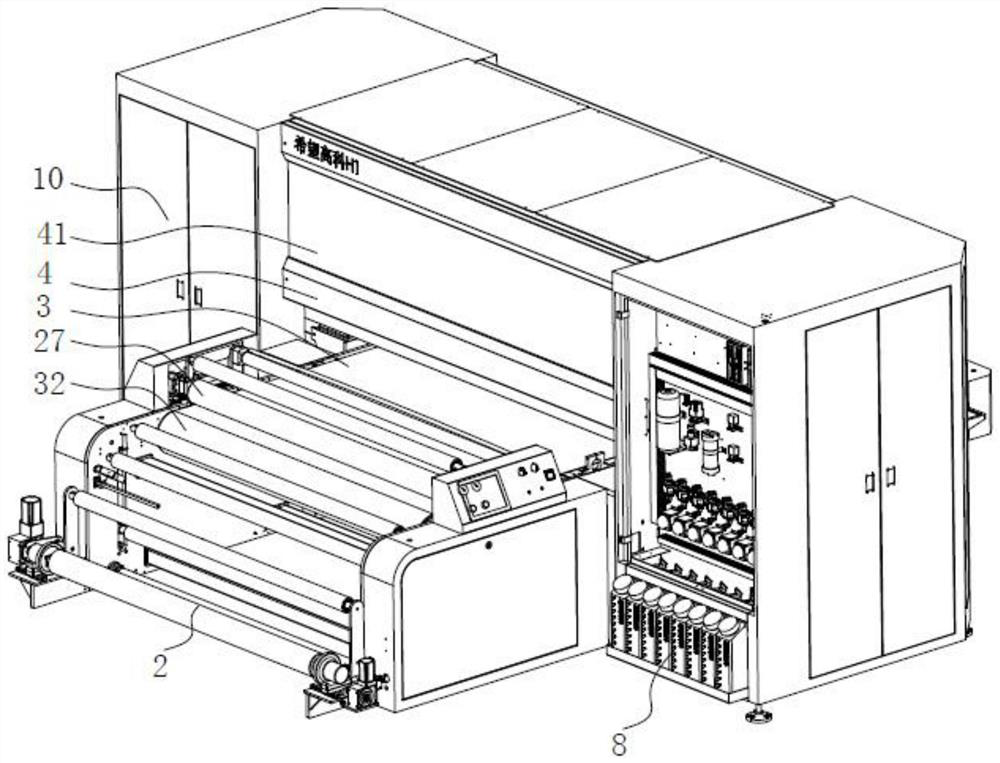

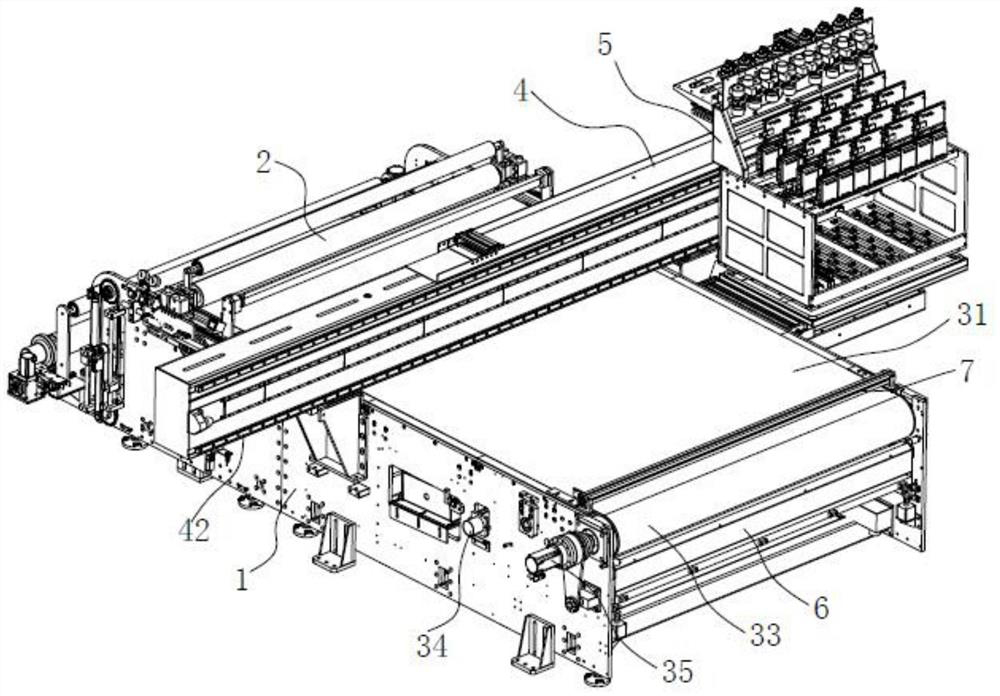

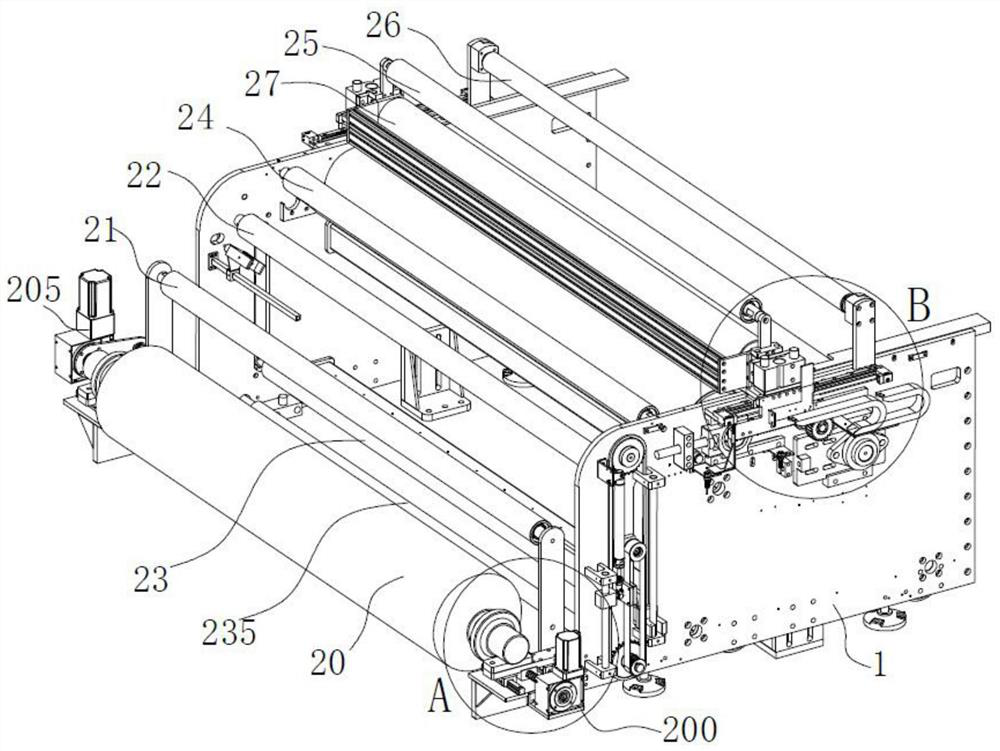

[0076]SeeFigure 1 ~ 2 The scanned textile digital printing apparatus of the present invention includes a rack 1 and an upper cloth mechanism 2 provided on the rack 1, a printing conveyor belt mechanism 3, a gantry carriage 4, a printing scanning vehicle 5, a belt rubber delay Apparatus 7, belt cleaning device 6, print control cabinet 10, and ink system 8; printed conveyor belt mechanism 3 is disposed at top, and the gantry carriage 4 across the print conveyor belt mechanism 3, belt cloth rubber delay The device 7 is disposed above the printed conveyor belt mechanism 3, and the upper cover mechanism 2 is disposed behind the printing transport belt mechanism 3, and the belt cleaning device 6 is disposed under the printing conveyor belt mechanism 3, the print control cabinet 10 is disposed in the gantry Next to the side of the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com