Intelligent carbon contact strip pressing machine with bracket edge folding function and using method thereof

A technology of carbon slides and pressing machines, which is applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of high labor intensity of operators, difficult bending, low efficiency, and danger of operators, so as to reduce the labor intensity of workers, Avoid manual folding and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

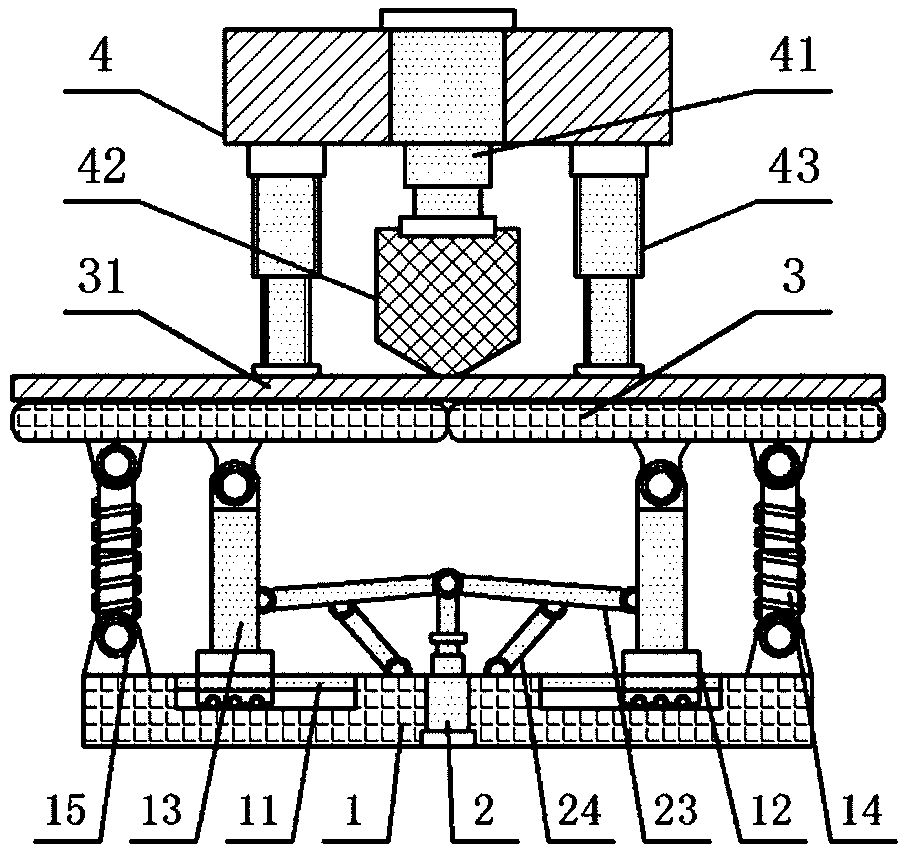

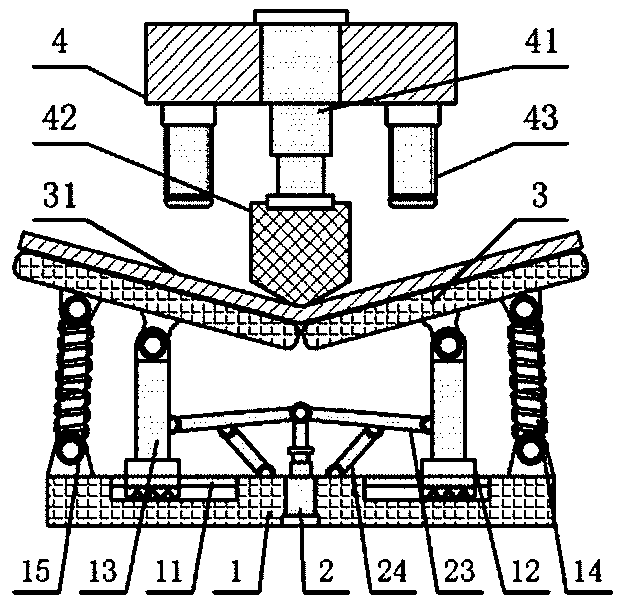

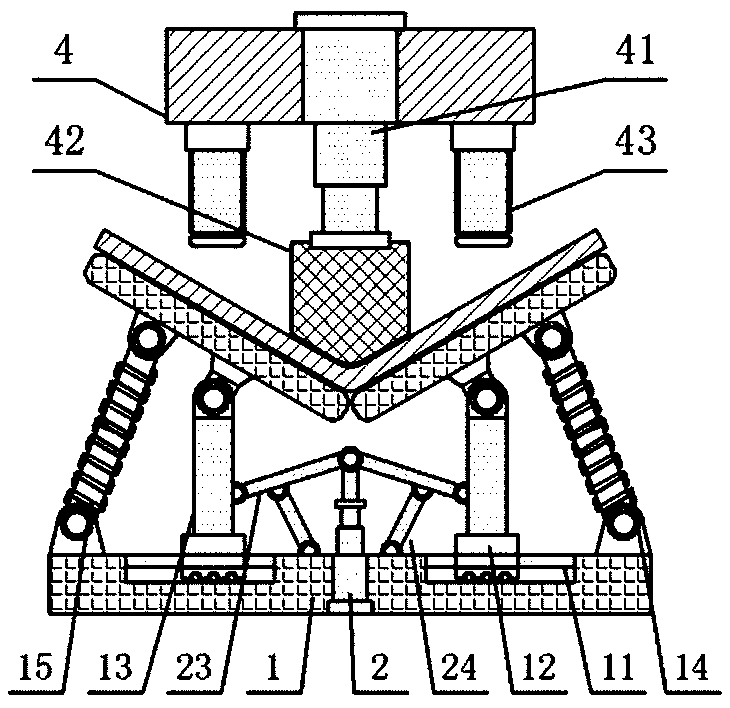

[0035] Embodiment 1: see Figure 1-5 , an intelligent carbon skateboard pressing machine with a bracket folding function, including a base plate 1, the base plate 1 is a rectangular plate placed horizontally, a telescopic cylinder groove is recessed in the center of the top surface of the base plate 1, and a telescopic cylinder groove is installed in the telescopic groove The telescopic cylinder 2, the top surface of the bottom plate 1 is located on both sides of the telescopic cylinder groove, and there are rectangular grooves recessed, and the sliding rods 11 are horizontally arranged in the rectangular grooves, and the sliding blocks 12 are horizontally sleeved on the sliding rods 11, The top surface of the slider 12 is equipped with a support rod 13; the top of the telescopic rod of the telescopic cylinder 2 and the middle part of the two support rods 13 are provided with a connecting rod mechanism, and the model of the telescopic cylinder 2 is DDA94-10-25;

[0036] The to...

Embodiment 2

[0043] Example 2: see Figure 6 , in this embodiment, the present invention also proposes a method for using an intelligent carbon skateboard pressing machine with a bracket folding function, including the following steps:

[0044] Step 1, the tail end of the telescopic cylinder 2 is electrically connected to the external power supply through the telescopic wire, the tail end of the hydraulic cylinder 41 is connected to the external air source through the hydraulic air pipe, and the tail end of the cylinder 43 is connected to the external air source through the air pipe.

[0045] Step 2, according to the bending angle of the workpiece 31, if the bending angle is large, the telescopic rod of the telescopic cylinder 2 is controlled to descend, and the linkage mechanism is adjusted to drive the support rod 13 and the slider 12 to move outward along the slider 11; The bending angle is small, the telescopic rod of the telescopic cylinder 2 is controlled to rise, and the linkage mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com