Forming die for composite dual-insertion lug piece of solar energy unmanned aerial vehicle engine compartment

A composite material and molding die technology, which is used in household appliances, other household appliances, household components, etc., can solve the problem of difficult to ensure the aerodynamic shape and assembly accuracy of composite material parts, and achieve uniform appearance, consistent quality and time saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

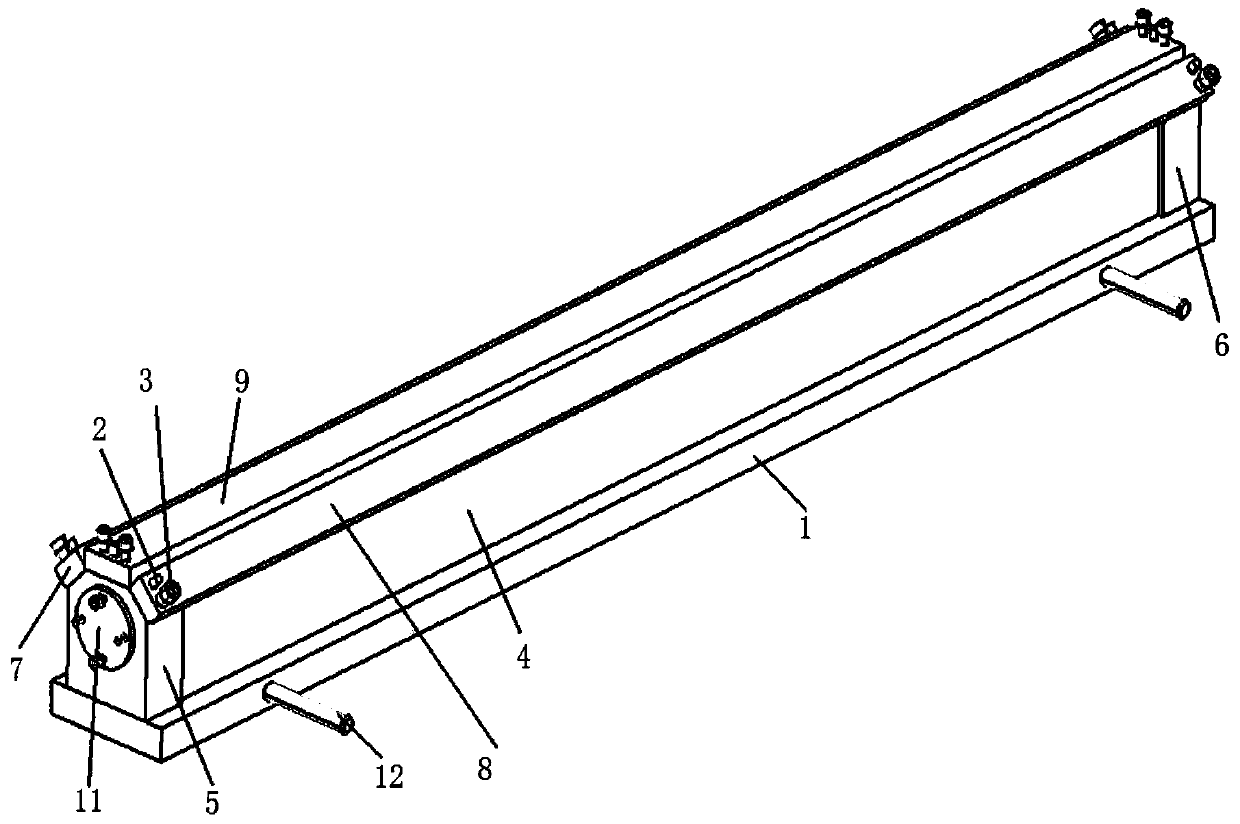

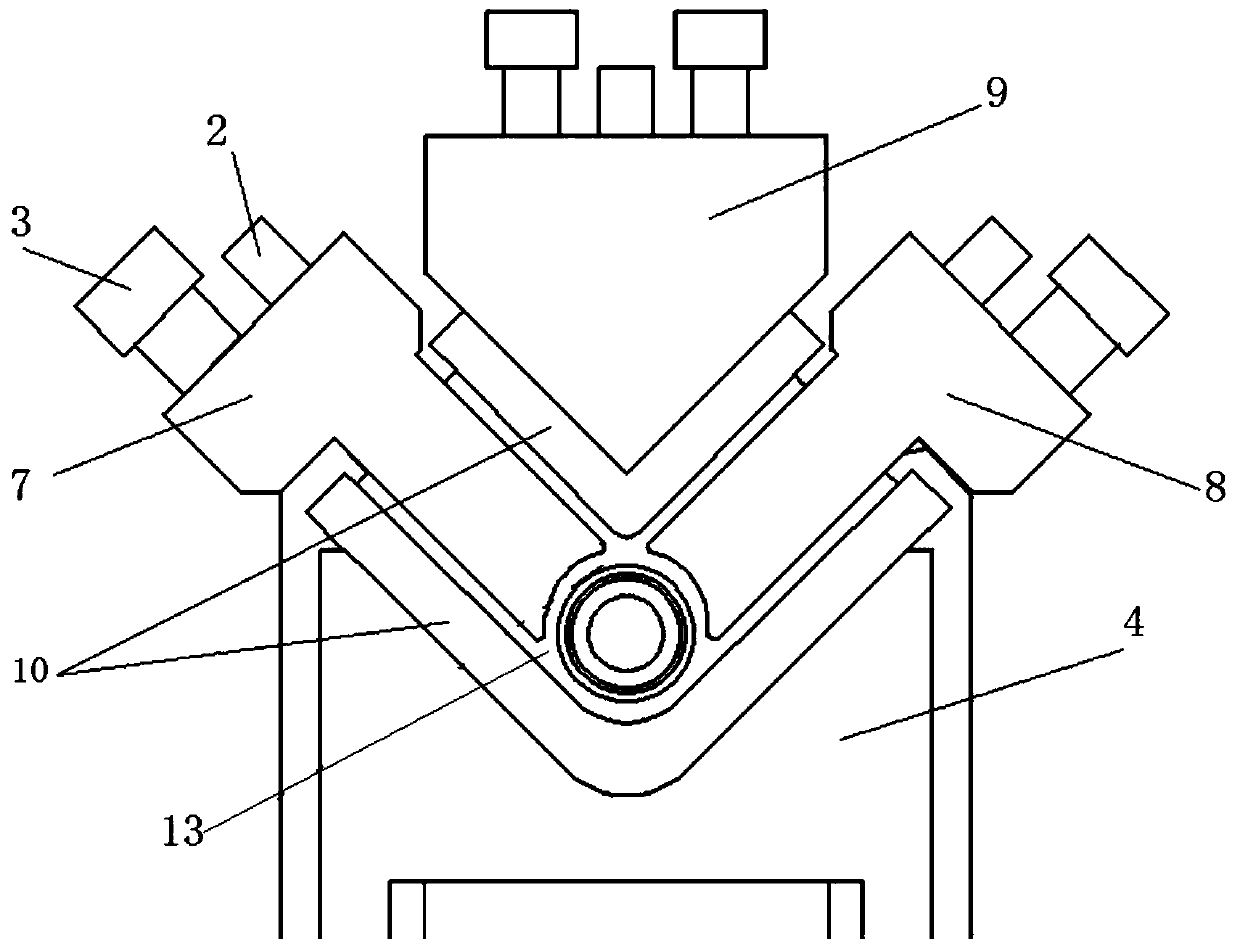

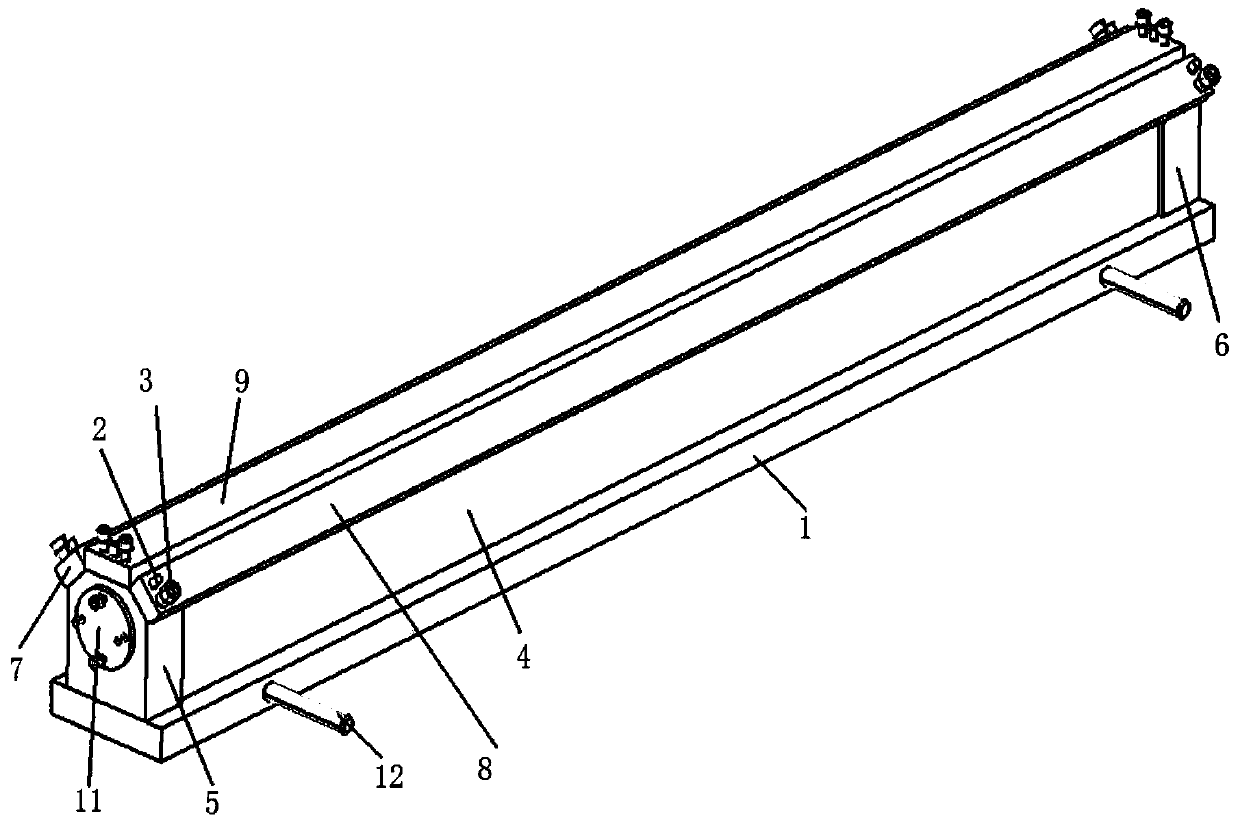

[0015] according to figure 1 , 2 As shown, the present embodiment provides a molding die for a composite material double-insert lug of a solar unmanned aerial vehicle power cabin, including a connecting base plate 1, positioning pins 2 and fastening bolts 3, and the connecting base plate 1 is provided with a support type mold 4, and the connecting bottom plate 1 at both ends of the supporting mold 4 is respectively provided with a first fixed seat 5 and a second fixed seat 6, and the left side above the first fixed seat 5 and the second fixed seat 6 is installed with The left side model 7, and the right side above the first holder 5 and the second holder 6 is equipped with a right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com