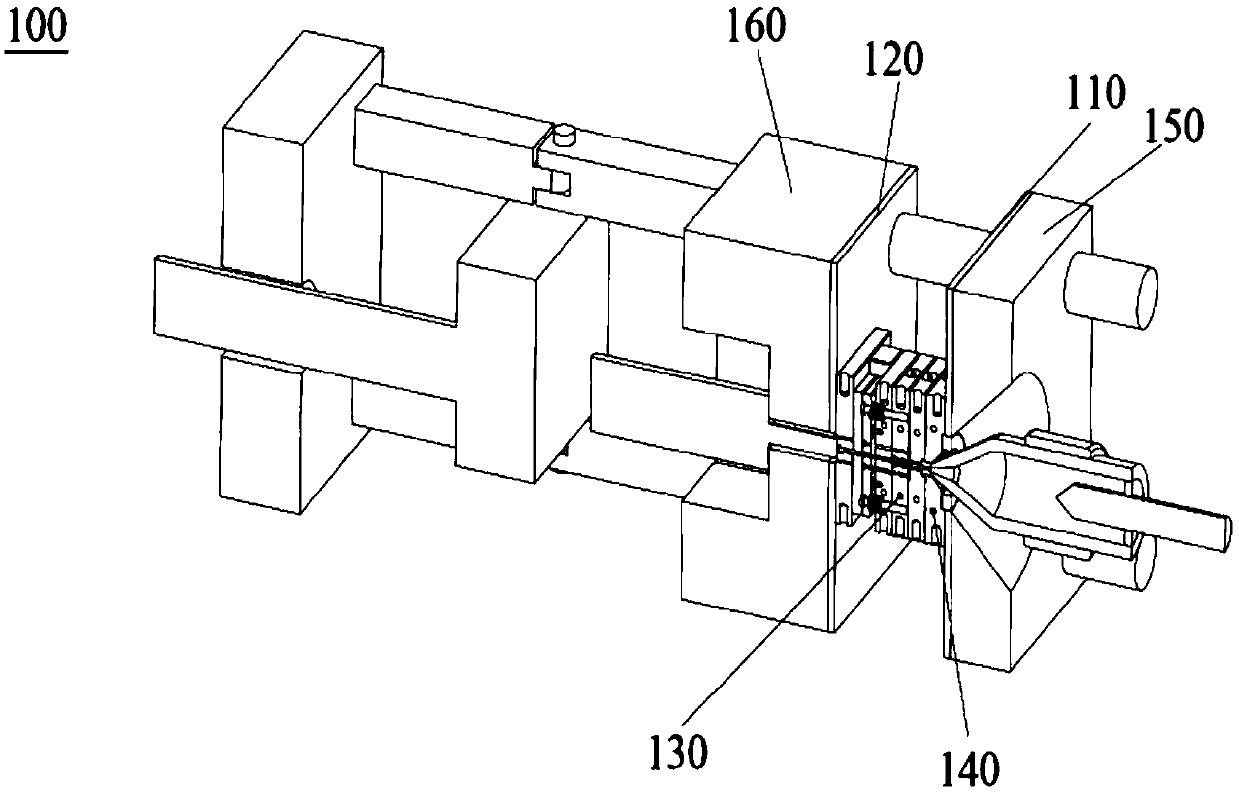

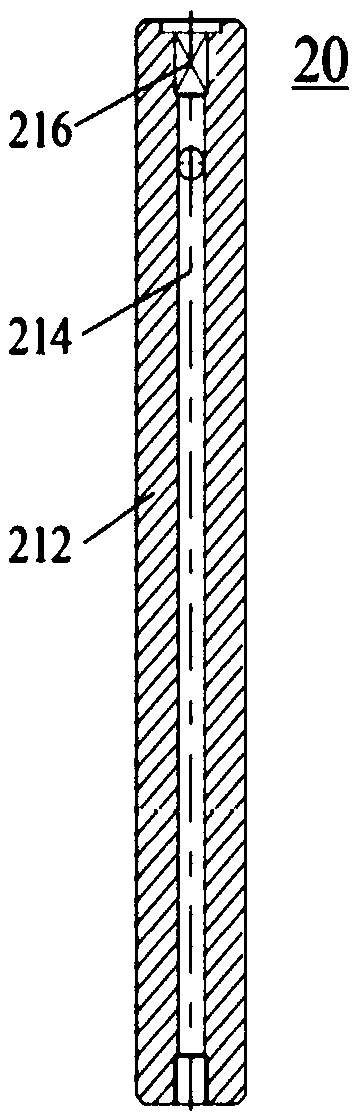

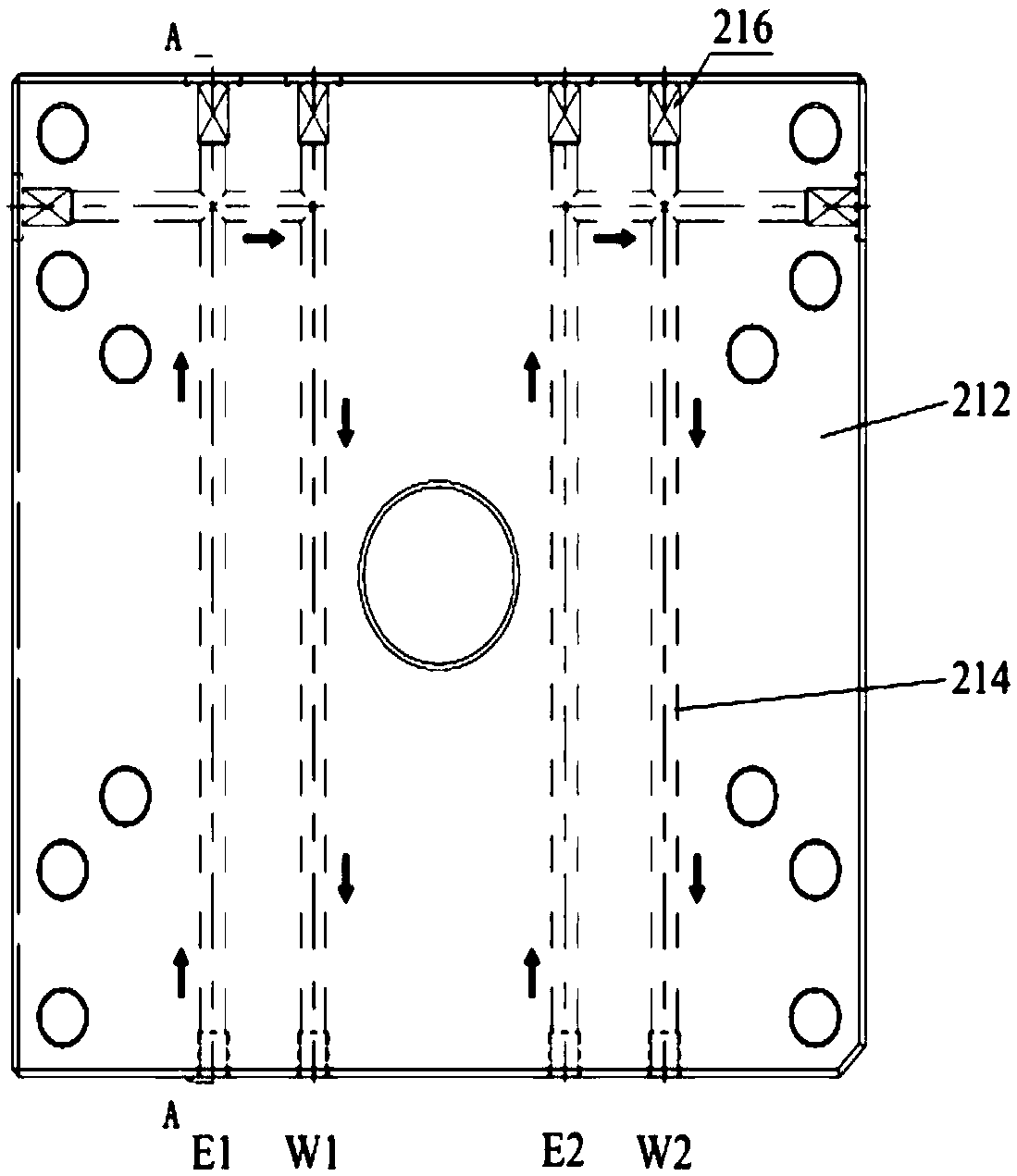

Heat insulating structure device, injection molding machine and method for controlling heat transfer and deformation quantity to be consistent

A technology of injection molding machine and mold temperature controller, which is applied in the field of injection molding machines and heat insulation structure devices, and can solve the problem of affecting the surface shape of the lens, the stability of the eccentricity, the service life of the mold, and the parallelism of the machine locking template affected by the fiber heat insulation board , The large difference in the deformation of the locking plates on both sides, etc., to reduce the mold clamping error, improve the stability, and improve the service life of the mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] For a better understanding of the application, various aspects of the application will be described in more detail with reference to the accompanying drawings. It should be understood that these detailed descriptions are descriptions of exemplary embodiments of the application only, and are not intended to limit the scope of the application in any way. Throughout the specification, the same reference numerals refer to the same elements. The expression "and / or" includes any and all combinations of one or more of the associated listed items.

[0059] It should also be understood that the terms "comprises", "comprises", "has", "comprises" and / or "comprising", when used in this specification, means that there are stated features, integers, steps, operations , elements and / or parts, but does not exclude the existence or addition of one or more other features, integers, steps, operations, elements, parts and / or their groups. Furthermore, expressions such as "at least one of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com