Gear finish machining grinding positioning mechanism

A positioning mechanism and grinding machine technology, which is applied to gear cutting machines, metal processing equipment, gear tooth manufacturing devices, etc., can solve problems such as difficult operation, positioning accuracy size deviation, and inconvenient processing, so as to reduce labor intensity and high degree of automation , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

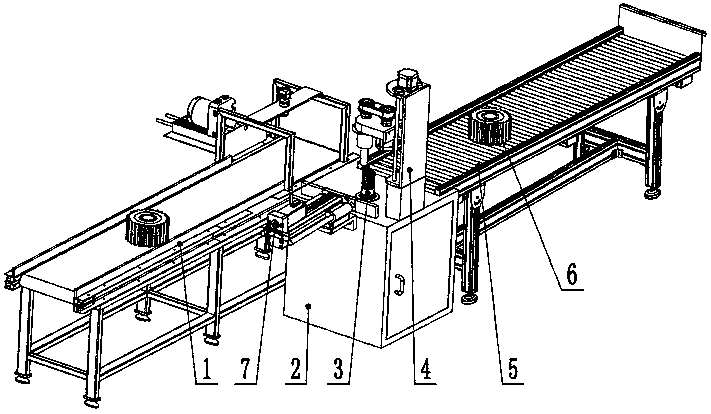

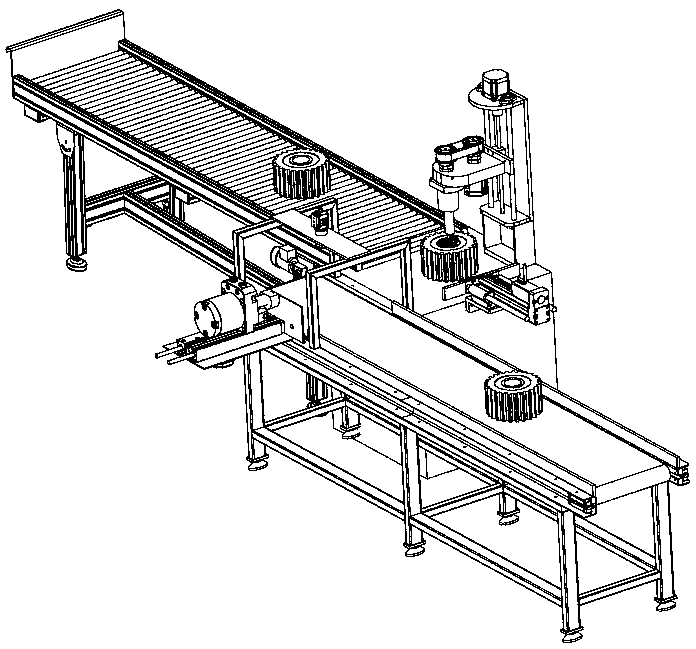

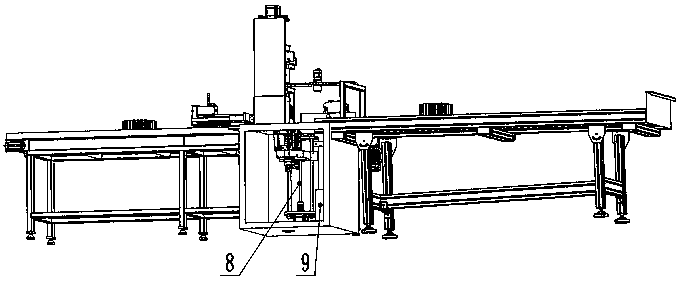

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown is a gear processing deburring device. Including feeding device 1, fixed worktable 2, adjustable positioning device 3, grinding machine 4, unloading roller table 5, workpiece gear 6, unloading and pushing device 7, lifting mechanism 8, hydraulic station 9, fixed working table 2 It is a box-type frame structure, fixedly installed on the ground, with a movable door on the side, the grinding machine 4 is fixedly installed on one side of the upper plane of the fixed workbench 2, and the feeding and pushing device 7 is fixedly installed on the other side of the fixed workbench 2 On the side, its bottom surface is flush with the upper plane of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com