A kind of solid waste recycling method

A technology for solid waste and recycling, applied in the field of solid waste resource recycling, can solve problems such as poor recycling and utilization of solid waste, and achieve the effect of avoiding secondary pollution and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for resource utilization of solid waste, comprising the steps of:

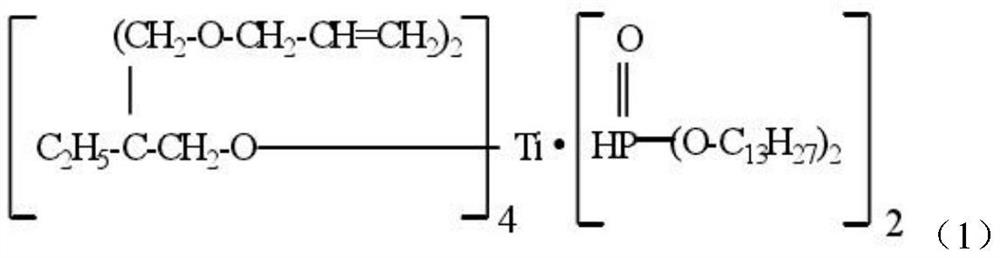

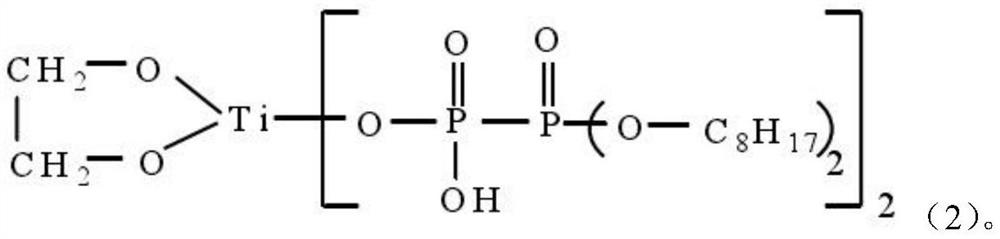

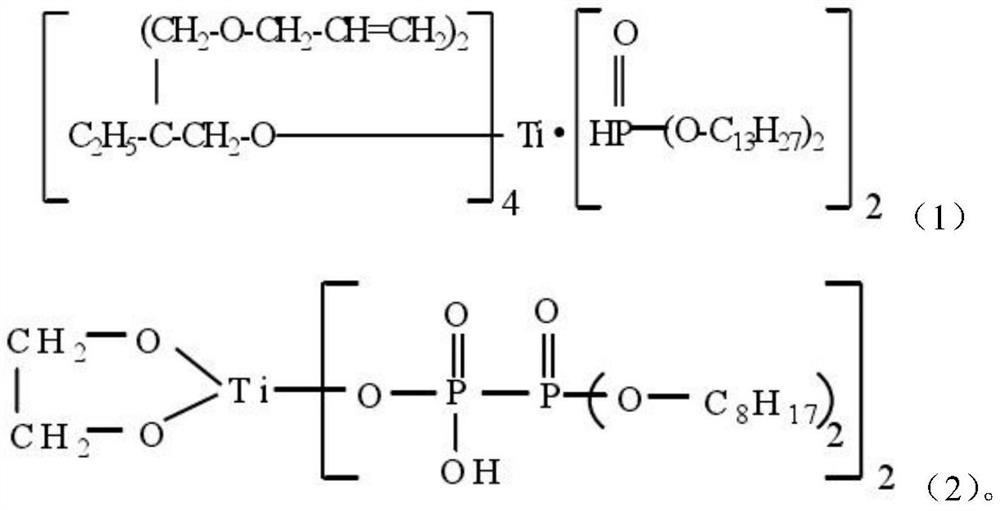

[0028] S1 Mix water and compound coupling agent, and ultrasonically disperse for 15 minutes to obtain compound coupling agent solution;

[0029] S2 mixing the solid waste with diatomaceous earth, stirring magnetically for 8 hours in a closed environment to obtain a solid waste-diatomite mixture;

[0030] S3 mixes the solid waste-diatomaceous earth mixture obtained in S2 with the complex coupling agent solution obtained in S1, and magnetically stirs for 2 hours to obtain a filler;

[0031] Among them, the solid waste is steel slag, the magnetic stirring device in S2 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is normal temperature, the magnetic stirring device in S3 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is 60 ° C, and the water in S1 is deionized water. The steel slag is converter hot slag, the particle size of th...

Embodiment 2

[0036] A method for resource utilization of solid waste, comprising the steps of:

[0037] S1 Mix water and compound coupling agent, and ultrasonically disperse for 20 minutes to obtain compound coupling agent solution;

[0038] S2 Mix the solid waste with diatomite, and magnetically stir for 9 hours in a closed environment to obtain a solid waste-diatomite mixture;

[0039] S3 mixes the solid waste-diatomaceous earth mixture obtained in S2 with the complex coupling agent solution obtained in S1, and magnetically stirs for 3 hours to obtain a filler;

[0040] Among them, the solid waste is steel slag, the magnetic stirring device in S2 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is normal temperature, the magnetic stirring device in S3 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is 65 ° C, and the water in S1 is deionized water. The steel slag is converter drum slag, the particle size of the steel sla...

Embodiment 3

[0045] A method for resource utilization of solid waste, comprising the steps of:

[0046] S1 Mix water and compound coupling agent, and ultrasonically disperse for 25 minutes to obtain compound coupling agent solution;

[0047] S2 Mix the solid waste with diatomite, and magnetically stir for 10 hours in a closed environment to obtain a solid waste-diatomite mixture;

[0048] S3 mix the solid waste-diatomaceous earth mixture obtained in S2 with the complex coupling agent solution obtained in S1, and magnetically stir for 4 hours to obtain a filler;

[0049] Among them, the solid waste is steel slag, the magnetic stirring device in S2 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is normal temperature, the magnetic stirring device in S3 is a constant temperature magnetic stirrer, and the magnetic stirring temperature is 70 ° C, and the water in S1 is deionized water. Steel slag is electric furnace hot slag, the particle size of steel slag is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com