Quick temperature control method for hot water in vacuum cup

A thermos cup and hot water technology, applied in the field of household appliances, can solve the problems of slow cooling speed and influence, and achieve the effect of simple and convenient cooling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The method for rapid temperature control of hot water in a thermos cup comprises the following steps:

[0059] S1: the user rotates the heat dissipation driving mechanism of the heat conduction heat dissipation device 200;

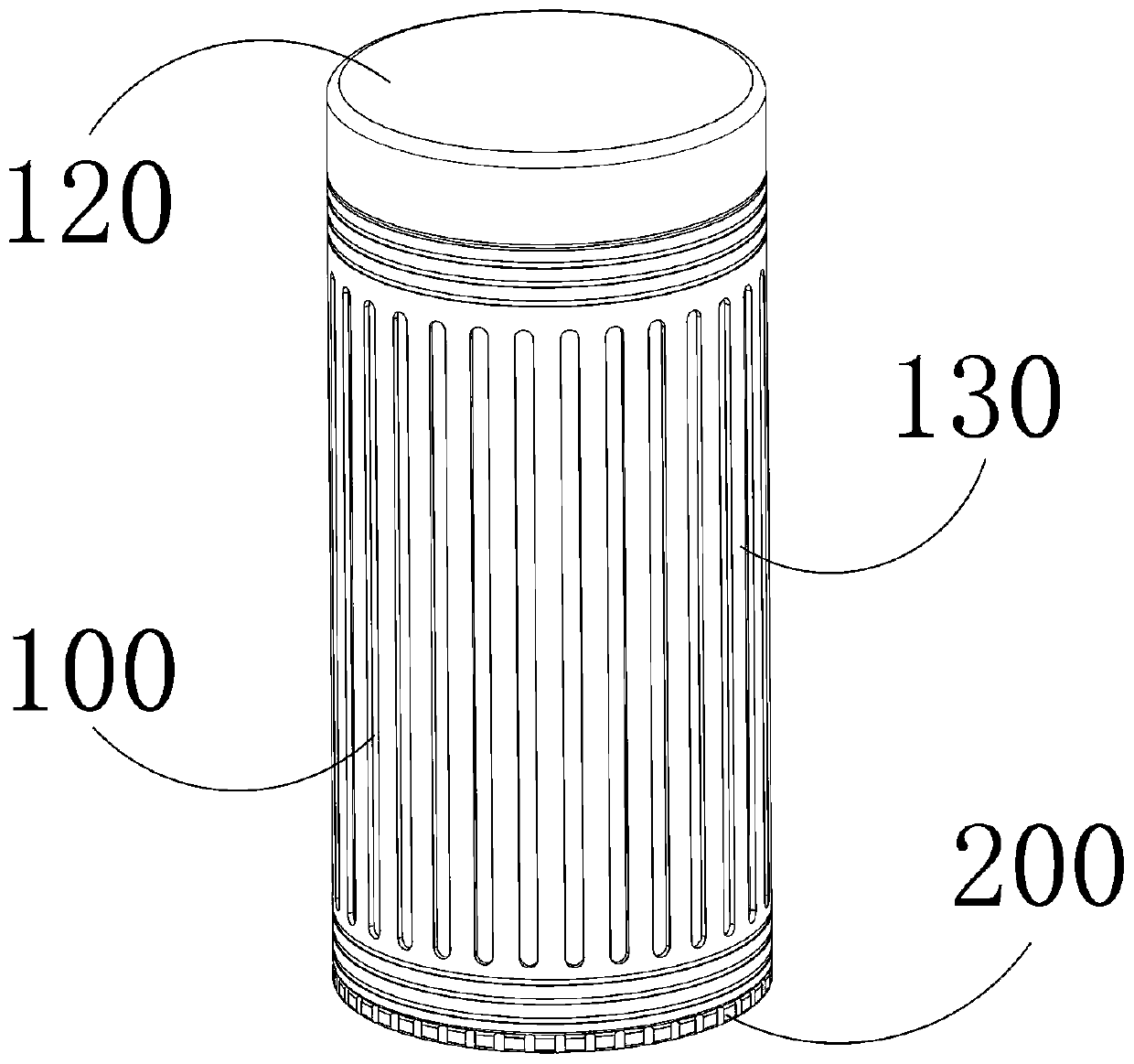

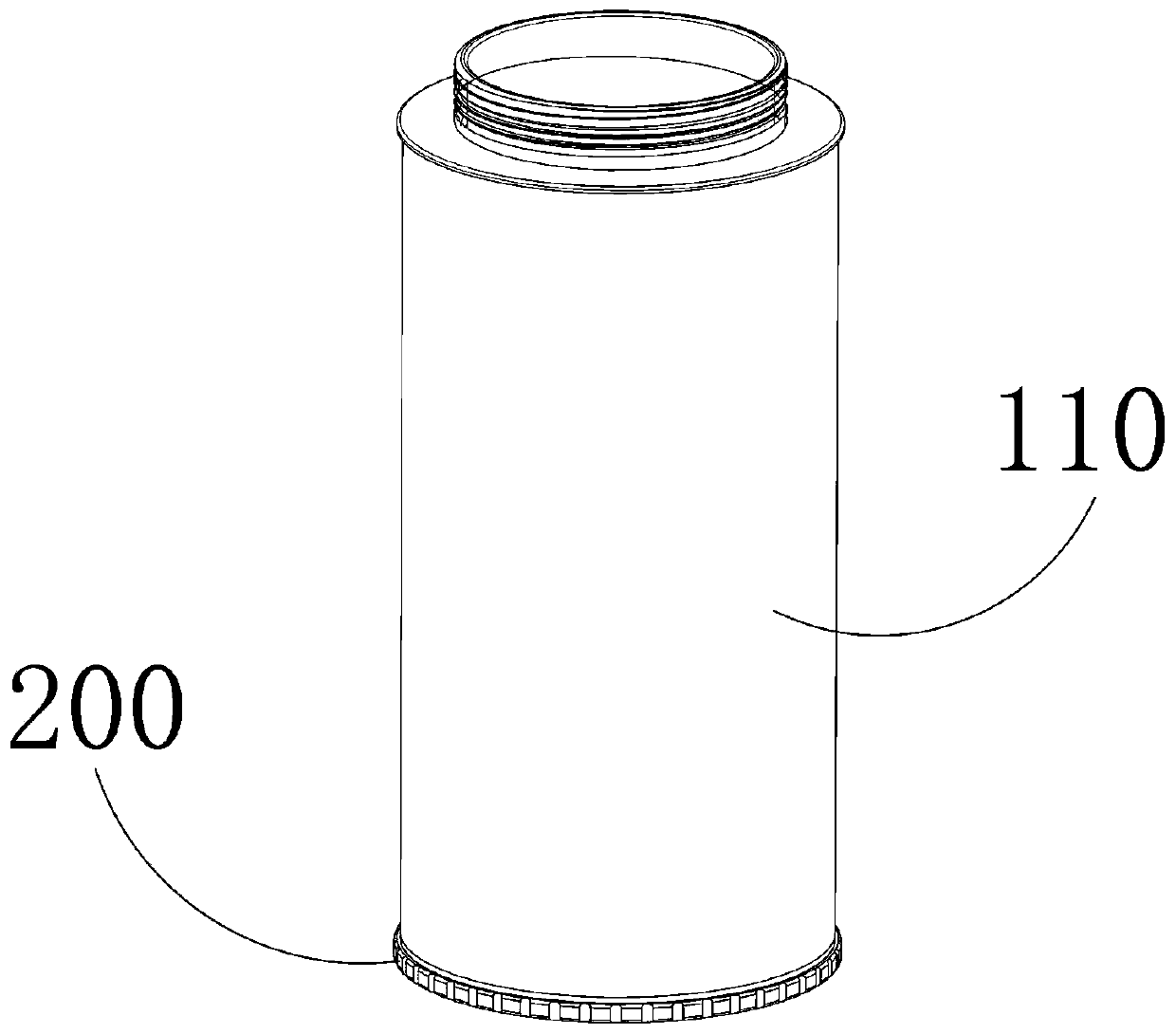

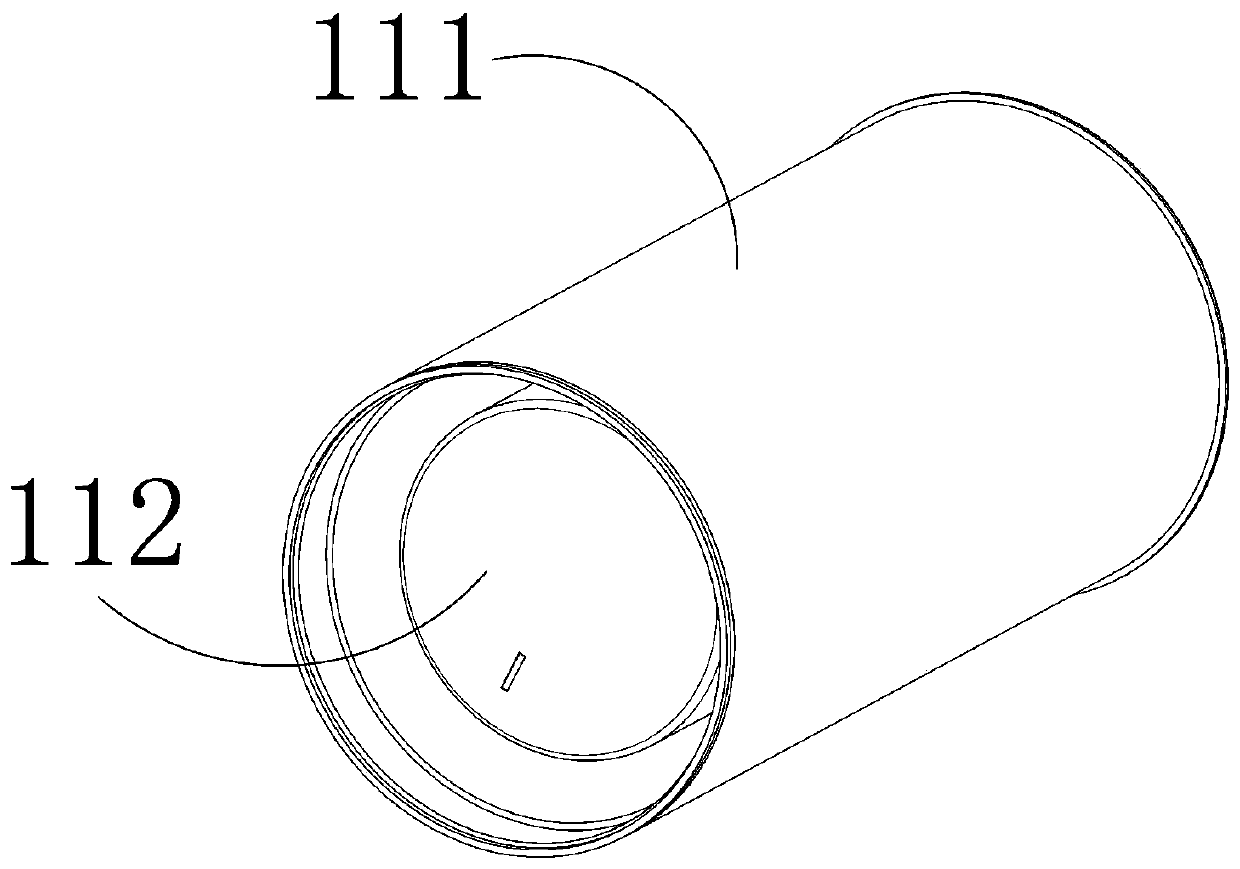

[0060] The thermos cup 100 includes a thermos cup body 110, and the thermos body 110 is divided into two parts, which are respectively an outer pot 111 and an inner pot 112;

[0061] The heat-conducting heat sink 200 includes a flap heat conduction mechanism 210 and a heat dissipation drive mechanism. The flap heat conduction mechanism 210 includes a fixed ring and a heat conduction member. Installed in the area between the inner tank 112 and the outer tank 111, the fixing ring is provided with two groups and is respectively an upper fixing ring 211 near the mouth of the thermos water cup 100, a lower fixing ring 212 near the bottom of the thermos water cup 100, and a lower fixing ring. The annulus of 212 is provided with piercing holes;

[0062] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com