Pulsed hydraulic fracturing with geopolymer precursor fluids

A technology of geopolymers and body fluids, applied in the direction of drilling compositions, production fluids, wellbore/well components, etc., can solve the problems of loss of initial conductivity, gel damage, etc., to eliminate demand, increase productivity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

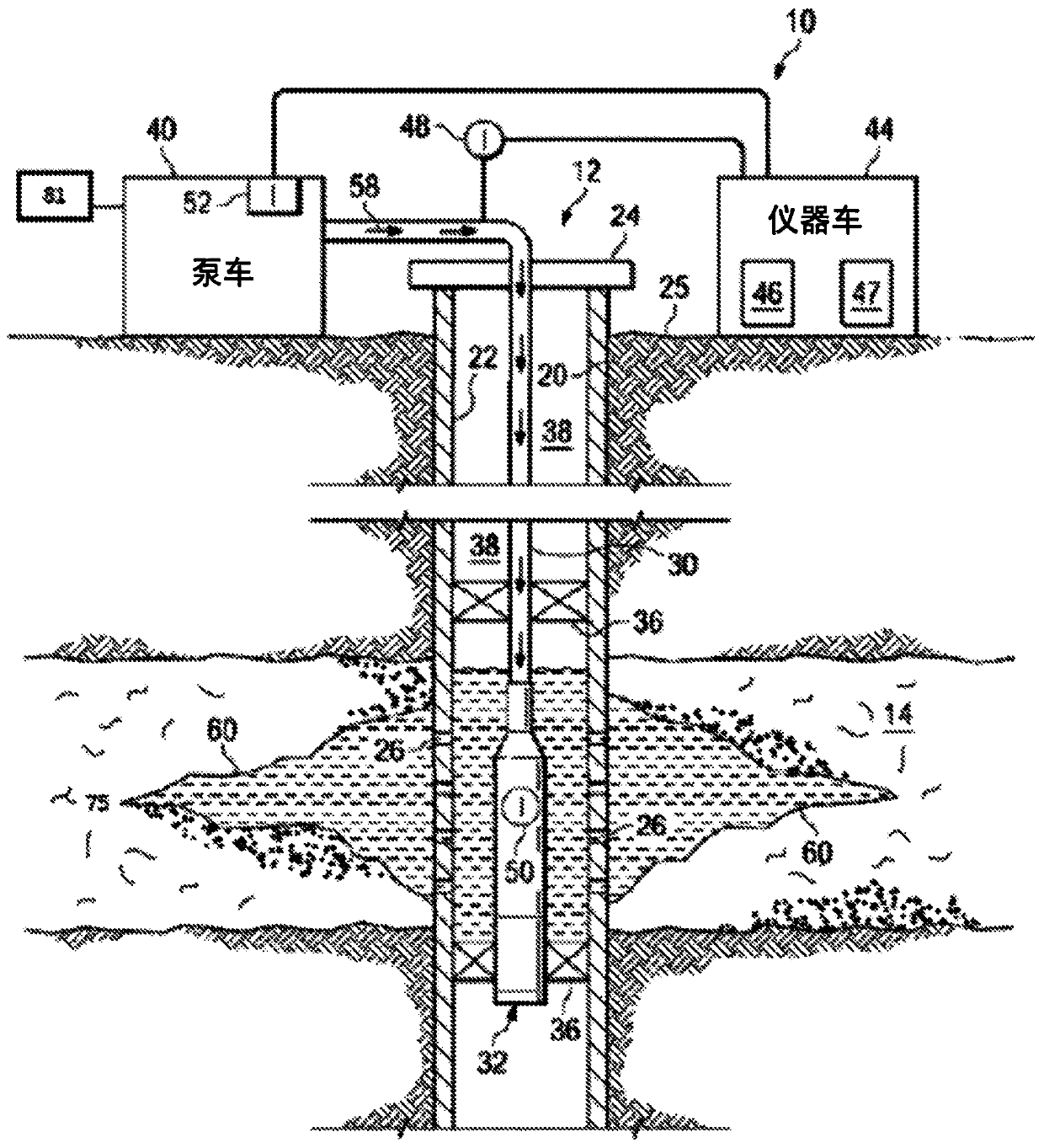

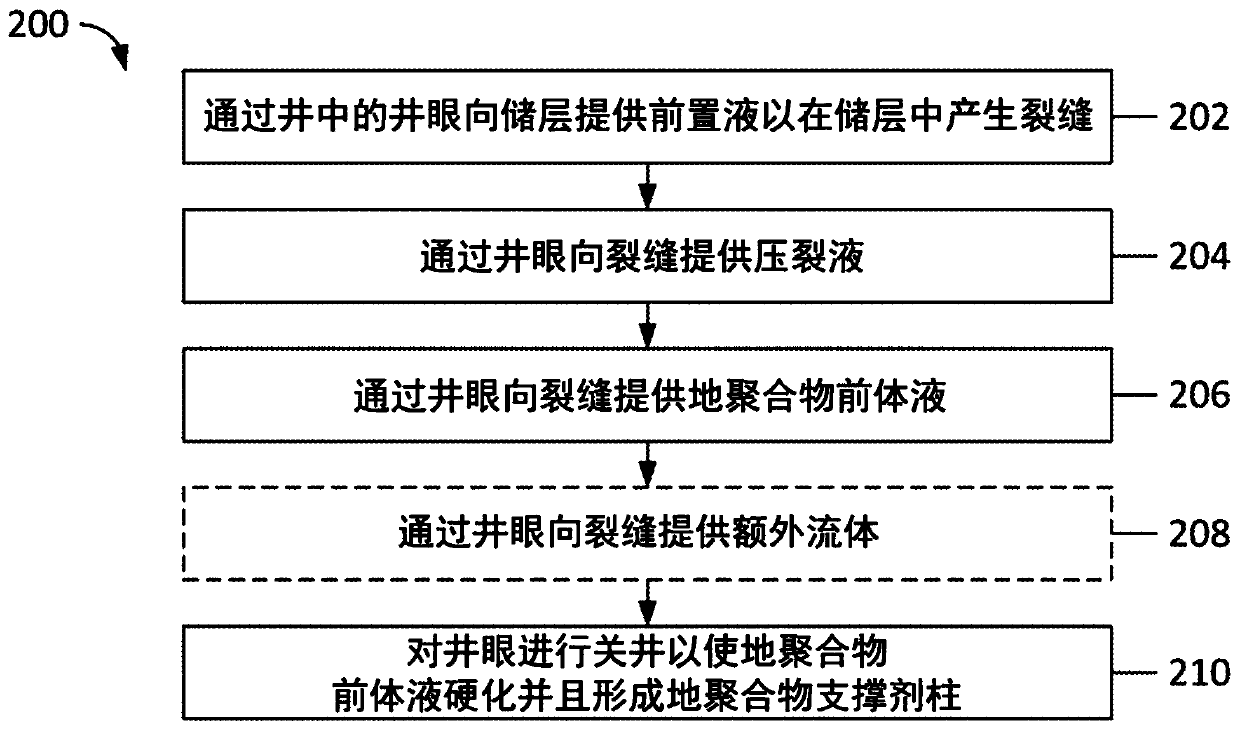

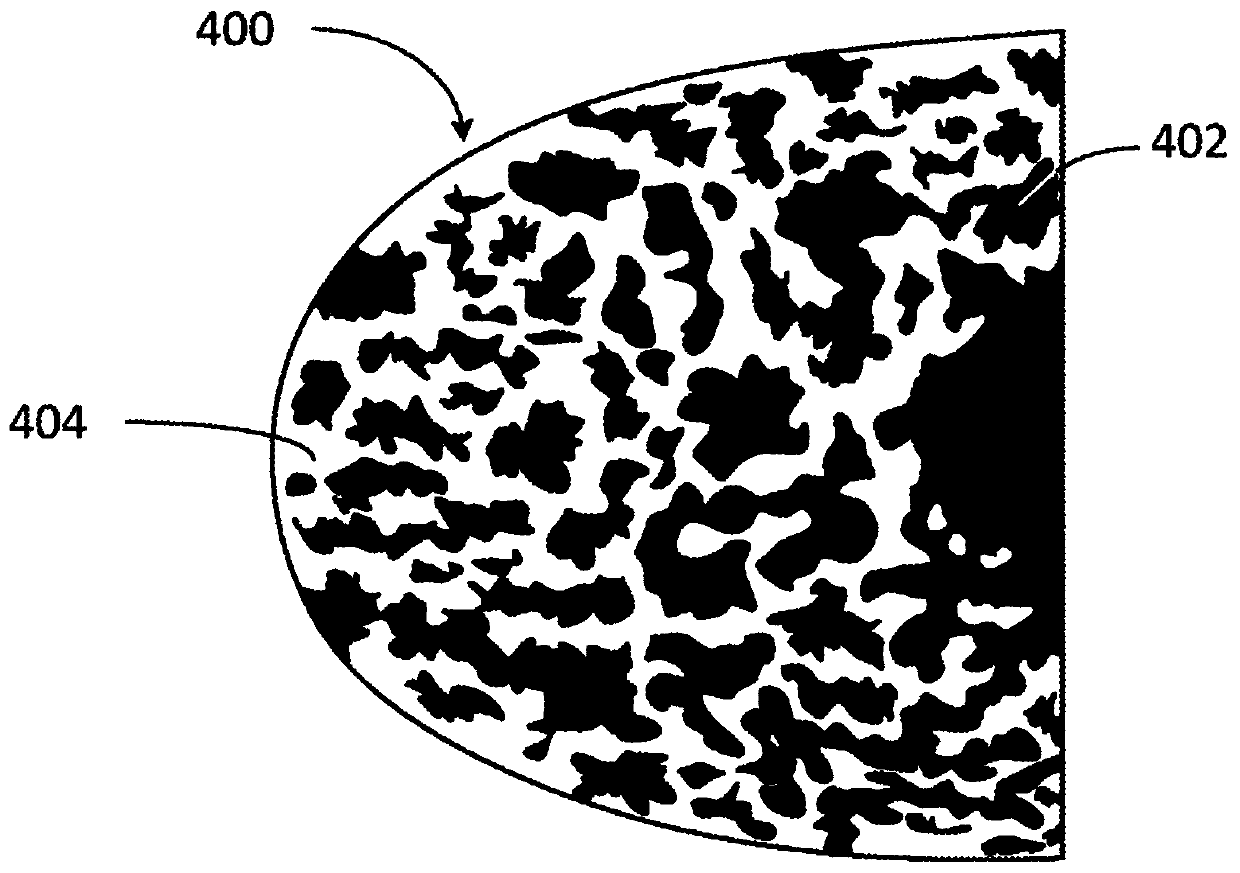

[0018] To avoid loss of conductivity of the proppant pack in the reservoir, separate proppant columns are formed to support the fracture and keep it open. The separated proppant columns form conductive channels that provide paths of high conductivity for hydrocarbon flow. As described herein, a stable proppant column is produced by providing a pulse of geopolymer precursor fluid within a compatible fracturing fluid, or by combining a pulse of geopolymer precursor fluid with a compatible fracturing fluid at fracture pressure. Pulses of fracturing fluid alternate through the wellbore and into the reservoir. The geopolymer precursor fluid contains an aluminosilicate, an alkaline agent and a penetration enhancer. The pulsed injection mode causes the geopolymer precursor fluid to fill the fracture in a discrete distribution shape, creating proppant columns in the fracture. The geopolymer precursor fluid hardens in the reservoir to form geopolymer proppant columns in the fractures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com