Solar cell module electrical performance test lead device

A solar cell module, electrical performance testing technology, applied in electrical components, photovoltaic power generation, photovoltaic system monitoring and other directions, can solve problems such as increasing electrical performance testing time, increasing the contact resistance of conductive cores, and reducing operator experience. The effect of eliminating bad experience, reducing measurement deviation, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

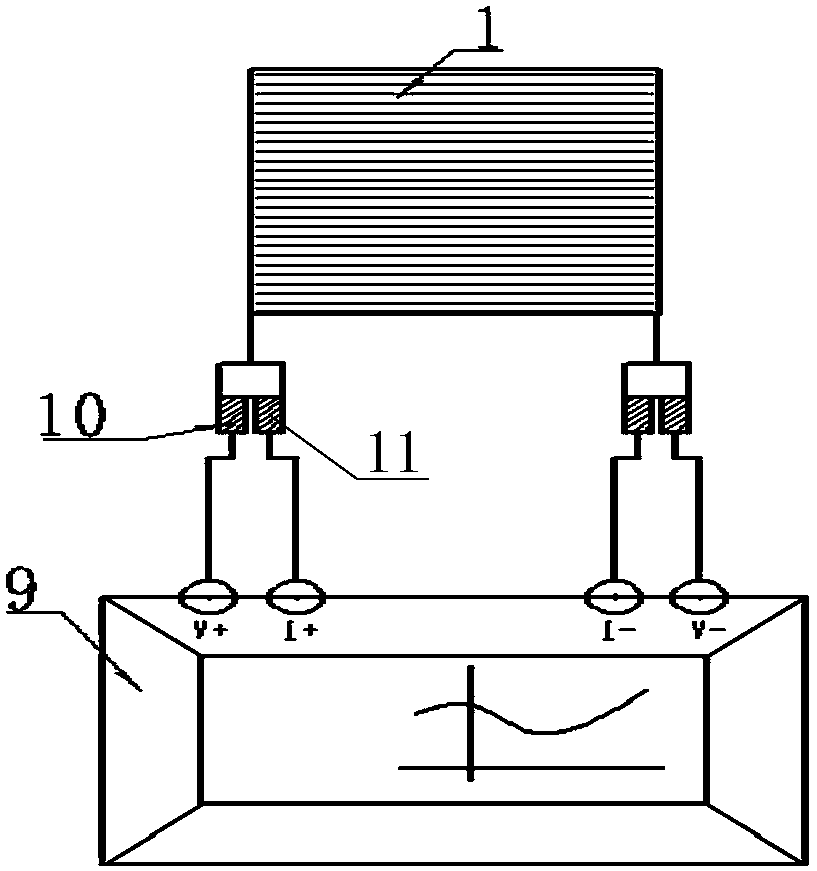

[0027] Solar cell module 1 electrical performance test lead device of the present invention, such as figure 1 Shown includes a piston module and a preset module; the piston module includes a support 6 that can reciprocate along a fixed track and an elastic conductive member 5; the elastic conductive member 5 is arranged on the aforementioned support 6; the elastic conductive member 5 and The electrical performance testing device 9 is electrically connected; the preset module includes a joint and a base 3; the base 3 is provided with a fixing device 2, and in this case, four air suction cups are selected as the fixing device 2; the bottom of the base 3 A conductive contact 4 is provided; the conductive contact 4 is electrically connected to the aforementioned connector. The support 6 is arranged on the top of the supporting mechanism 7, and the supporting mechanism 7 is arranged on the slider and its driving device 8. In this embodiment, the cylinder is selected as the slider a...

Embodiment 2

[0036] On the basis of Example 1, as Image 6 As shown, an implementation example of a pre-installed module uses a wedge 20 as the fixing device 2. The wedge 20 is located at one end of the base 3 and is integrally made with the base 3; the thicker part of the wedge 20 is thicker than the solar cell module 1 and its The distance between the flanging of the aluminum frame, and the thinner part of the wedge 20 is less than the distance between the solar cell module 1 and the flange of the aluminum frame; the base 3 of the pre-set module, with the end of the wedge 20, is pressed into the solar cell module 1 and its aluminum frame. Gaps in aluminum frame flanging, such as figure 1 as shown, figure 1 The flanging of the aluminum frame at the upper right corner will be clamped with the wedge 20 to fix the preset module.

[0037] The base 3 is provided with five conductive contacts 4 insulated from each other, four of which are arranged side by side and are used for the transmissio...

Embodiment 3

[0039] On the basis of Example 1, as Figure 7 As shown, an implementation case of a preset module adopts elastic clips as the fixing device 2; there are two elastic clips; the elastic clips are formed on the base 3 by springs 21, movable splints 22, shafts 23, etc.; The downward protrusion has a through hole on the protrusion, and the corresponding protrusion with the through hole on the base 3; the two through holes are passed through by the shaft 23, so that the movable splint 22 can surround the shaft 23, and the relative base 3 can Rotate within a certain range; such as Figure 7 As shown, the spring 21 is located between the movable splint 22 and the base 3, forcing the left end of the movable splint 22 to be raised, so that the right end of the movable splint 22 is engaged with the base 3; to prevent falling off;

[0040] During use, the function of fixing the preset module can also be achieved by engaging the flange of the aluminum frame of the solar cell module 1 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com