Intelligent temperature control device for mass concrete

A large-volume concrete and intelligent temperature control technology, which is applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of constant temperature and flow that cannot be adjusted in time, the temperature difference of cooling water exceeds the allowable value, and the quality of concrete construction risks and other issues to achieve the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

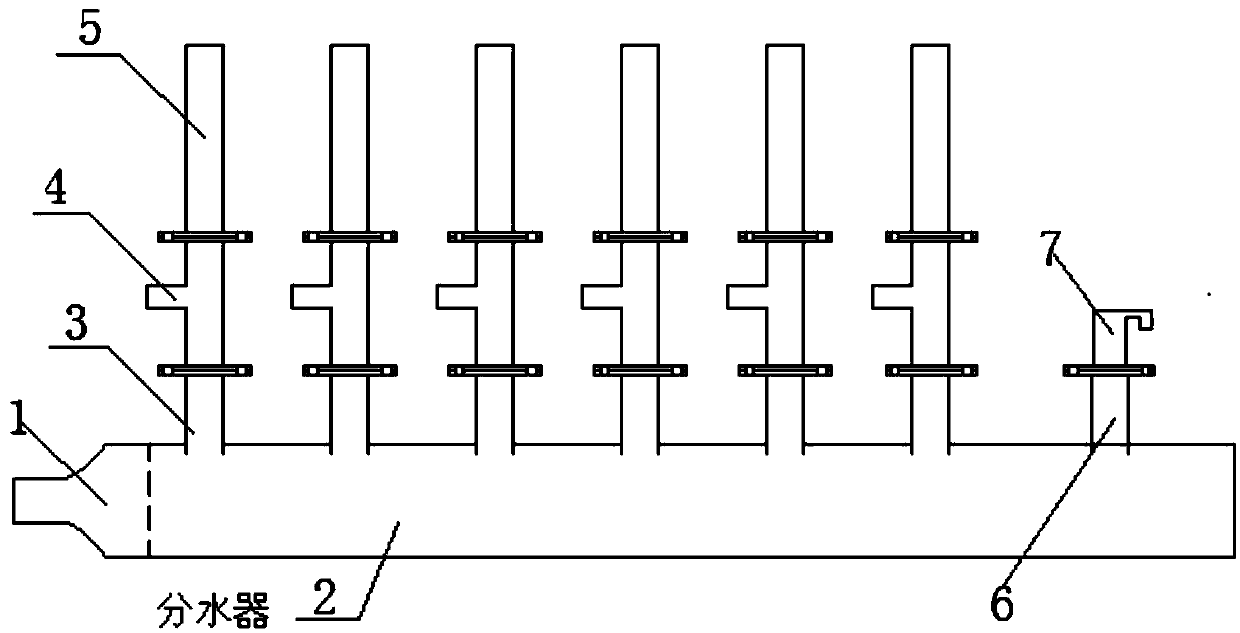

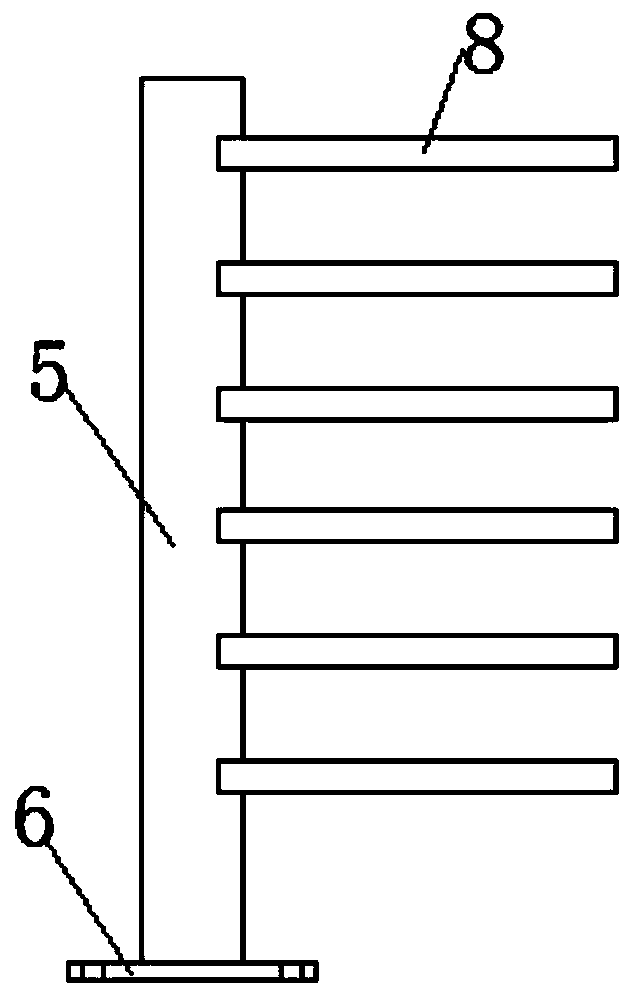

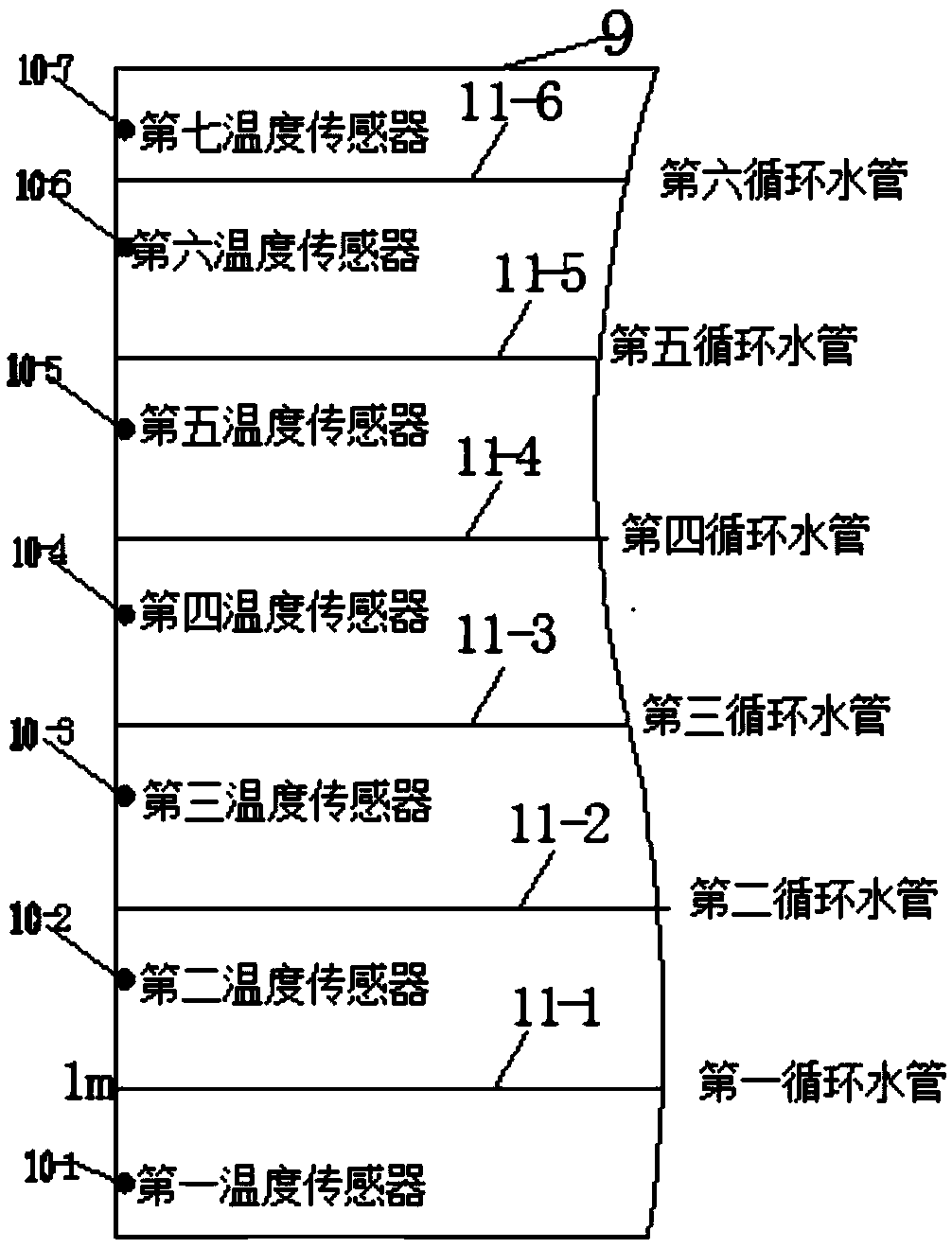

[0022] The embodiment of the present invention is as figure 1 , figure 2 , image 3 and Figure 4 As shown, a large-volume concrete intelligent temperature control device is characterized in that: the water inlet of the water distributor 2 and the outlet pipe of the booster pump are installed together with a reducer, and one end of the six lower branch pipes 3 is welded to the On the round hole of the water distributor 2; use the first bolts to install the flanges at both ends of the electromagnetic valve 4 with the same structure and the first flange 6a at the upper end of the lower branch pipe 3 and the second flange 6b at the lower end of the upper branch pipe 5 fixed together; 2 to 6 branch pipes 8 are vertically welded on the upper branch pipe 5 respectively, and the top of the upper branch pipe 5 is a closed structure; Connect the water inlet of each layer of the circulating water pipe in the platform 9, respectively connect the outlet of the circulating water pipe t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com