FRP sheet connecting structure of prefabricated concrete beam and slab system and method

A technology of prefabricated concrete and FRP sheets, which is applied to floors, building components, building structures, etc. It can solve the problems of difficult transportation and hoisting operations, low production efficiency, low construction efficiency, etc., and achieves good waterproof and anti-seepage effects and convenient construction , The effect of reducing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

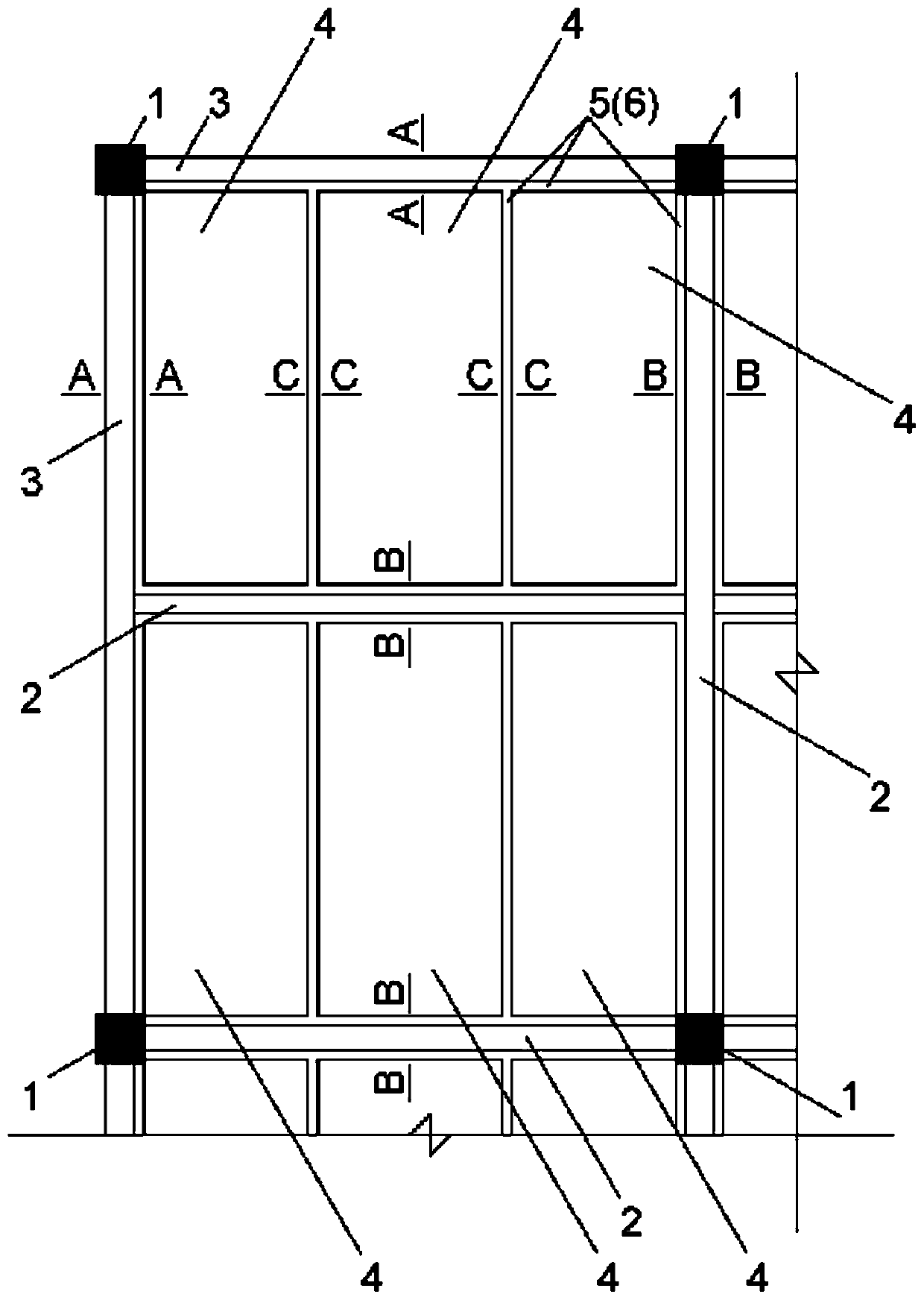

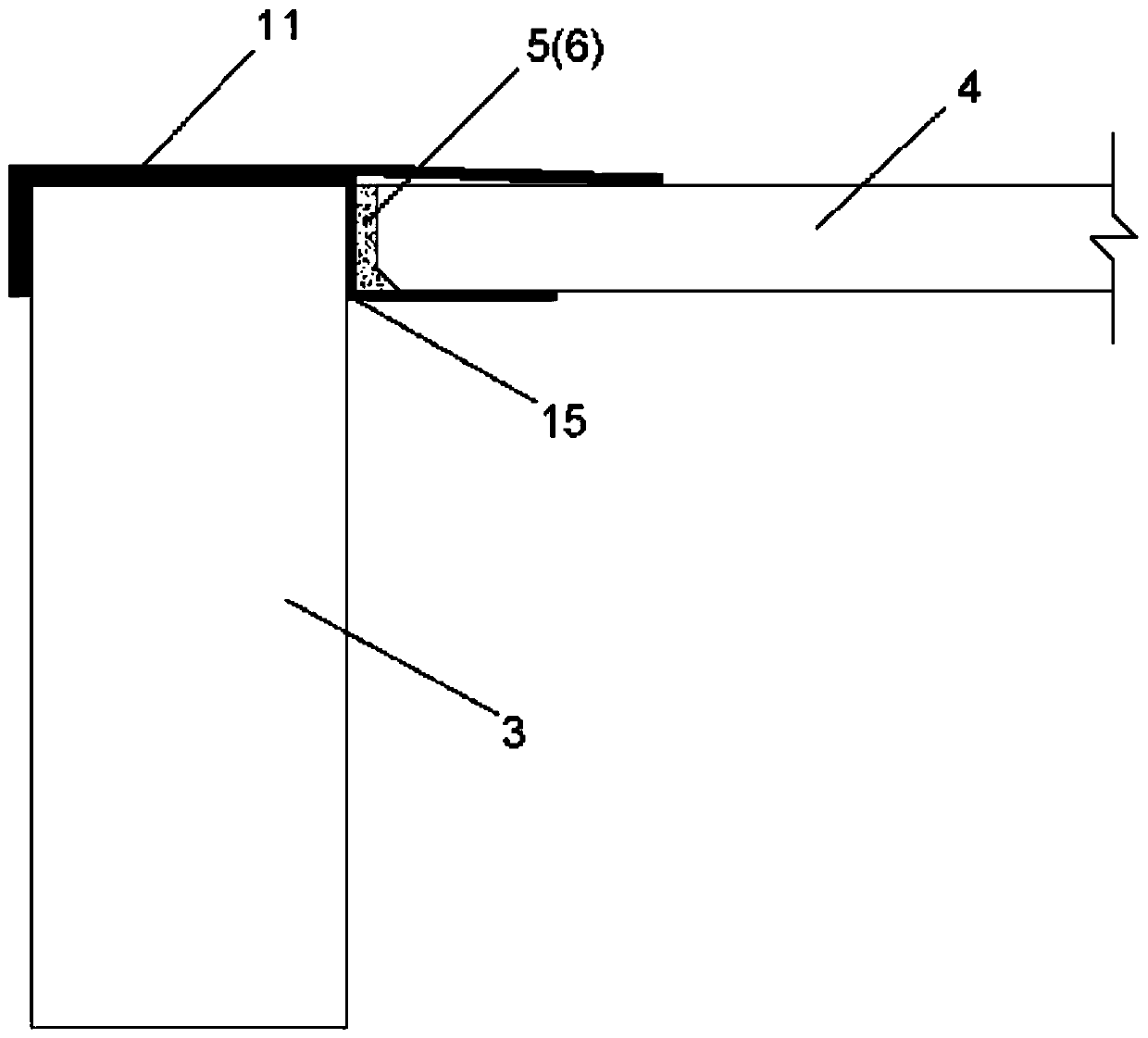

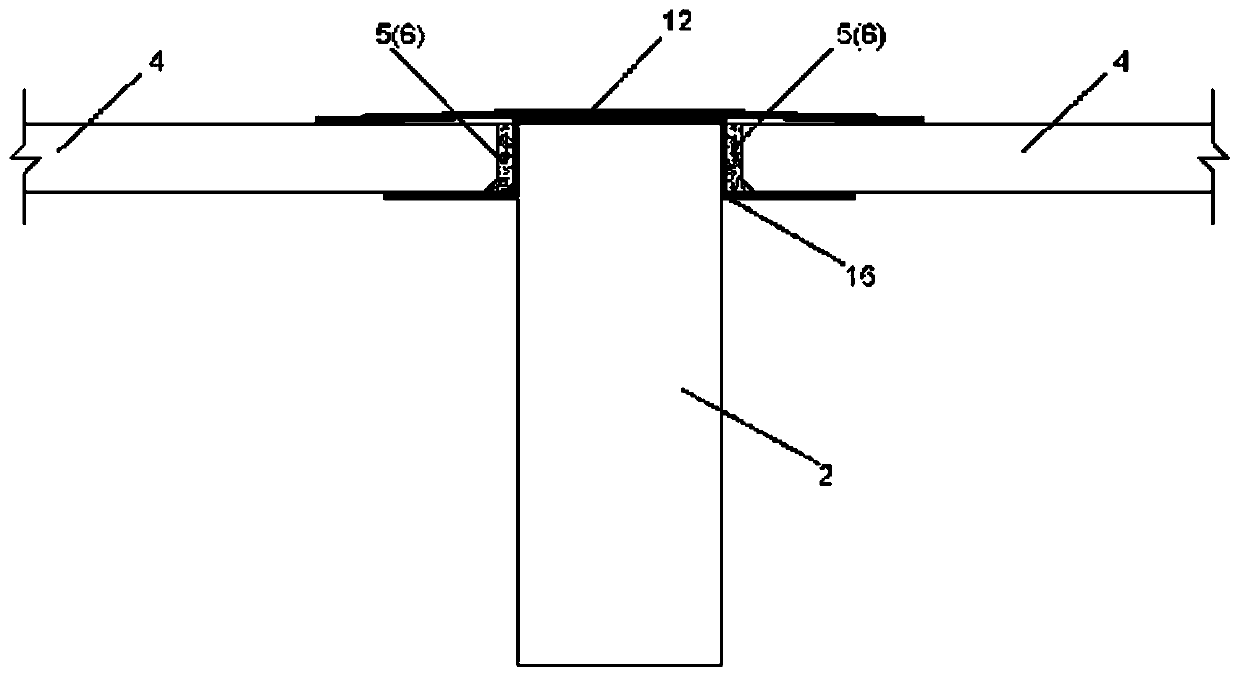

[0033] Such as Figure 1-5 Shown is a FRP sheet connection structure of a prefabricated concrete beam-slab system. The concrete beam-slab system includes 1, inner beam 2, side beam 3 and prefabricated slab 4. The inner beam 2 and side beam 3 are based on the existing mature technology Supported on the column 1 or other inner beams 2 or side beams 3, the surrounding sides of the prefabricated panel 4 are adjacent to the sides of the inner beams 2 or side beams 3; the cross-sections of the inner beams 2 and side beams 3 are both regular rectangles ; The planar shape of the prefabricated slab 4 is rectangular, and the octagons around the prefabricated slab 4 are chamfered with a height of about 20 mm.

[0034]The FRP sheet connection structure is adopted at each connection part of the prefabricated slab 4, and all the FRP sheet connection structures are divided into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com