Whole span pre-prefabricated prestressed groove-type rib plate, floor cover structure and assembly method thereof

A prestressing and groove-shaped technology, applied to floors, building components, building structures, etc., can solve the problems of complex side forms of prefabricated components, small units of prefabricated components, poor connection integrity, etc., to shorten the construction period on site, simplify the edge Die, ensure the effect of negative bending moment transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

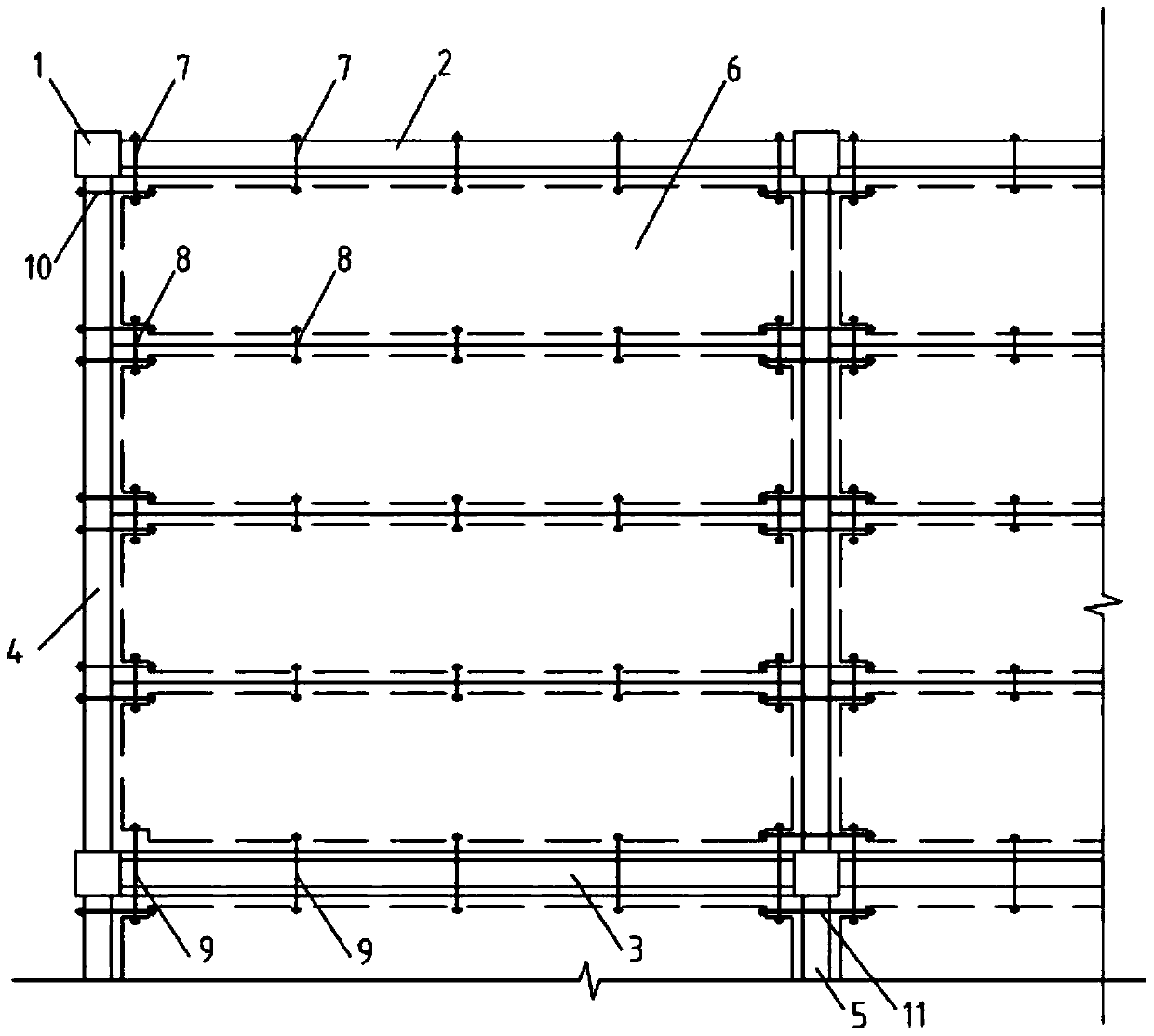

[0038] Such as figure 1 Shown is a prestressed assembled channel rib floor structure, the whole span prefabricated prestressed channel rib 6 spliced on the outer longitudinal frame beam 2, inner longitudinal frame beam 3, outer transverse frame beam 4, inner transverse frame On the frame beams composed of beams 5, the outer longitudinal frame beams 2, inner longitudinal frame beams 3, outer transverse frame beams 4, and inner transverse frame beams 5 are supported on the frame column 1.

[0039] According to the layout of the frame beams, divide the beam grid surrounded by the frame beams into blocks. The principle of division depends on the requirements of the design situation. Combined with this example, it is divided into four one-way slabs along the direction of the longitudinal frame beams. After the division, the plates Width is as large as possible within cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com