A Water-jet Loom Weft Insertion Pump with Adjustable Water Pressure

A technology of water jet loom and water pressure, applied in the fields of water jet loom and weft insertion pump of water jet loom, can solve the problem of small density variation range, and achieve good maintenance-free performance, stable machine movement and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

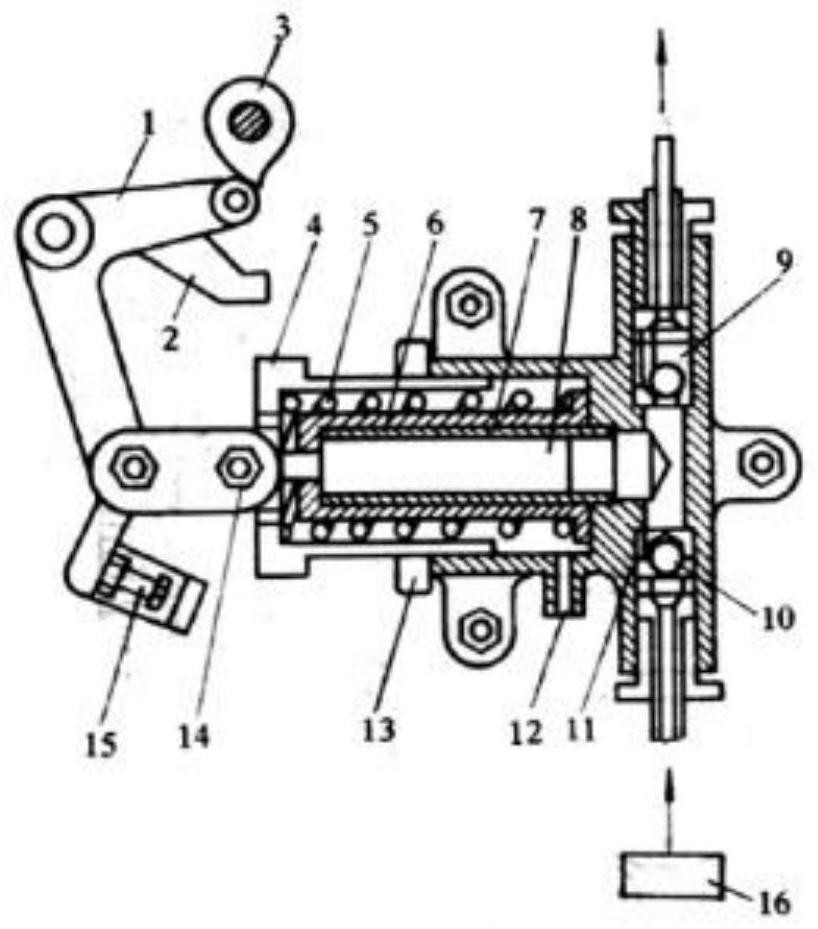

[0021] Such as figure 1 As shown, the principle of the water spray pump of the present invention is as follows: during the rotation of the cam 3 from a small radius to a large radius, the rotor of the angular lever 1 is pressed to rotate clockwise around the axis of the angular lever, driving the connecting rod 14 and the connected piston 8 outward. (i.e. the left side in the figure) moves, and the spring inner seat 6 fixed on it is pulled to slide along the cylinder liner 7 surface, and the spring 5 is compressed. At this time, due to the negative pressure, water passes through the space between the water inlet valve 10 piston and the cylinder liner in the pump body from the water tank 16 to realize the process of "pumping water".

[0022] When the cam 3 rotates from a large radius to a small radius, the rotor of the angular lever 1 can rotate counterclockwise around the axis of the angular lever due to the decrease of the radius. Due to the release of the elastic potential e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com