Intelligent assembling device based on robot assembly line

An assembly device and assembly line technology, applied in packaging, transportation and packaging, bottle/container caps, etc., can solve problems that affect the subsequent use of products, easy to wear caps, poor adaptability, etc., achieve a high degree of automation, improve practicability, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

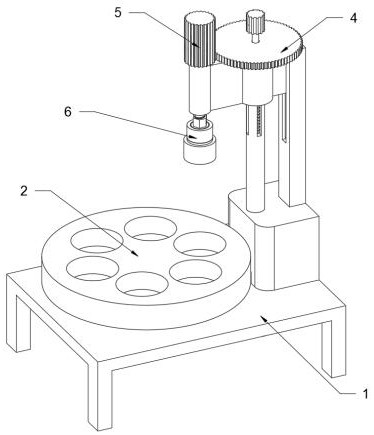

[0037] Append figure 1 Adherent Figure 5 Down:

[0038] The present invention provides a smart assembly device based on robotic pipeline, including mount 1;

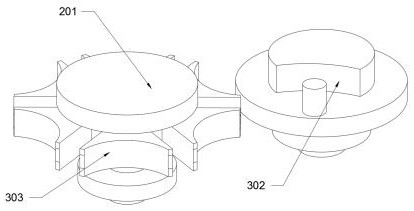

[0039] The mounting member 1 includes a working platform 101 and a support column 102 that fixes the side of the top surface of the working platform 101; the distribution tray 2, the distribution disk 2 rotates the top of the working platform 101, and The inner portion of the disk 2 is opened; the drive assembly 3, the drive assembly 3 includes a drive motor 301 and a groove mechanism, and the drive motor 301 is fixedly mounted at the bottom of the working platform 101, and the groove mechanism is from the active dial 302 and the driven groove. The wheel 303 is composed, and the active dial 302 and the driven groove 303 are rotatably connected to the top surface of the working platform 101, and the bottom portion of the active dial 302 is driven to the top end of the drive motor 301; the drive motor 301 and the external powe...

Embodiment 2

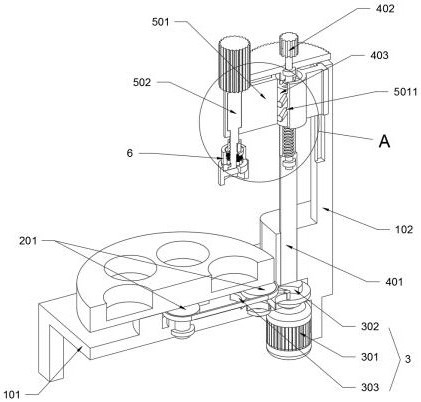

[0044] Append figure 1 Adherent Figure 10 Distance

[0045] On the basis of the first embodiment, the outer side of the cylinder assembling the cartridge 403 is provided with an assembly control groove, and the interior of the mid-fitting control block 501 is provided with a linkage projection 5011, and the linkage projection 5011 is inserted in the assembly control slot. Internal, in use, the assembly 6 can automatically raise the bottle body and the cap while the distribution disc 2 is rotated, and the assembly 6 can decrease the rotation of the bottle cap while the fitting disk 2 is fixed. Comparison.

[0046] Among them, the inner portion of the assembled cartridge 403 is provided with a "ten" glyph, and the intersecting the shaft body in the interior shaft 401 is provided with the synchronous groove 4012, and the follower 4031 is inserted inside the synchronous groove 4012, in which the linkage rotation shaft is used. When it is rotated by the active dial 302, the synchronous...

Embodiment 3

[0049] Append figure 1 Adherent Figure 10 Distance

[0050] Based on Example 1 and Example 2, the internal portion of the active control block 601 is provided with a torque control post 6011, and the bottom of the torque control post 6011 is a spherical design, and a hemispherical linkage concave is provided at the bottom of the disc mounting disk 604. The groove 6041, and the bottom of the torque control post 6011 is inserted inside the linkage recess 6041, in which the tightening torque of the assembly body 6 can be adjusted, when the rotational torque is larger than the setting torque after the assembly 6, the assembly 6 can be The idle protection bottle cap will not be worn.

[0051] Among them, the inner portion of the torque control column 6011 is provided with a torque joined spring 6012, and both ends of the torque joins 6012 are respectively coupled to the inside of the torque control post 6011 and the bottom portion of the adjustment damper 603, in use, rotary regulatory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com