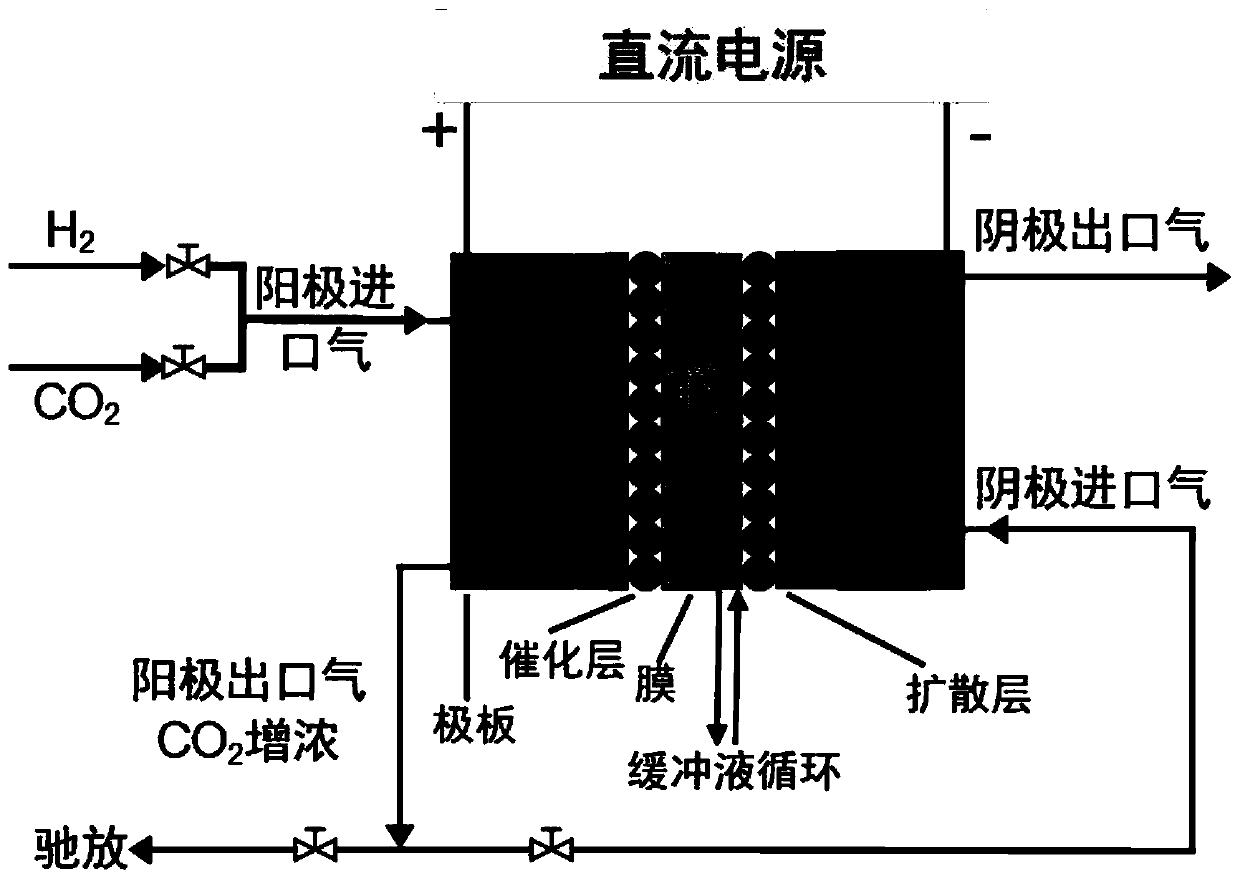

H2/CO2 separation and CO2 hydrogenation self-coupling method

A CO2 and self-coupling technology, applied in the field of electrochemical engineering, can solve the problems of lack of reference in the design of electrochemical hydrogen pump coupling process, and achieve the effects of improving safety and operability, reducing costs, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the electrochemical hydrogen pump reactor, the anode is hydrogen-containing CO with a hydrogen gas integration rate of 20%. 2 Mixed gas feed, the feed amount is 20sccm; the buffer solution is KHCO with a concentration of 0.5mol / L 3 , The circulation flow rate is 15mL / min, and the cathode catalyst loading capacity is 2mg / cm 2 , the anode catalyst loading is 0.5mg / cm 2 , the anode outlet adopts zero discharge to pass all the outlet gas into the cathode, and the flow rate is 18 sccm. When the electrochemical hydrogen pump reactor with a constant current of 30mA / cm 2 , After 30min at 25°C, the cathode potential is -1.25V, CO 2 The reaction rate of hydrogenation to form formic acid is 70.5mmol / (s cm 2 ), the current efficiency is 57.5%, CO 2 The conversion rate of 4.0%, H 2 The utilization rate was 16.0%.

Embodiment 2

[0024] In the electrochemical hydrogen pump reactor, the anode is hydrogen-containing CO with a hydrogen gas integration rate of 75%. 2 Mixed gas feed, the feed amount is 25 sccm, the buffer solution is KHCO with a concentration of 1.5mol / L 3 , The circulation flow rate is 10mL / min, and the cathode catalyst loading capacity is 1.5mg / cm 2 , the anode catalyst loading is 0.2mg / cm 2 , the anode outlet adopts zero discharge to pass all the outlet gas into the cathode, and the flow rate is 20 sccm. When the electrochemical hydrogen pump reactor with a constant current of 3mA / cm 2 , After running at 25°C for 30 minutes, the cathode potential is -0.74V, CO 2 The reaction rate of hydrogenation to form formic acid is 10.4mmol / (s cm 2 ), the current efficiency is 42.8%, CO 2 The conversion rate of H 2 The utilization rate is 0.75%.

Embodiment 3

[0026] In the electrochemical hydrogen pump reactor, the anode is hydrogen-containing CO with a hydrogen gas integration rate of 33.3%. 2 Mixed gas feed, the feed amount is 5 sccm; the buffer solution is KHCO with a concentration of 2.5mol / L 3 , The circulation flow rate is 12mL / min, and the cathode catalyst loading capacity is 3mg / cm 2 , the anode catalyst loading is 0.4mg / cm 2 , a part of the anode outlet is discharged, and a part is passed into the cathode, and the flow rate is 1 sccm. When the electrochemical hydrogen pump reactor with a constant current of 18.9mA / cm 2 , After 30min at 25°C, the cathode potential is -1.31V, CO 2 The reaction rate of hydrogenation to form formic acid is 27.1mmol / (s cm 2 ), the current efficiency is 27.6%, CO 2 The conversion rate was 6.5%, and the hydrogen utilization rate was 13.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com