Hydrocracking pretreatment method for high-nitrogen high-dry-point raw material

A technology of hydrocracking and high dry point, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve the problems of inability to deal with high nitrogen and high dry point feedstock oil, etc.

Pending Publication Date: 2020-05-05

CHINA PETROLEUM & CHEM CORP +1

View PDF15 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0010] The above method grades catalysts with different pore diameters, and the pore diameters of the catalysts gradually decrease along the flow direction. This method can

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

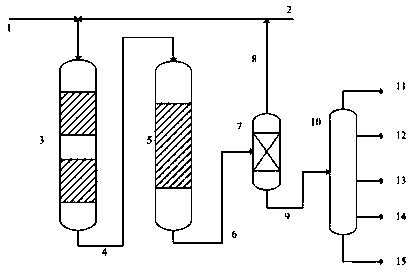

The invention discloses a hydrocracking pretreatment method for high-nitrogen high-dry-point raw oil. The method comprises the following steps: (1) under hydrofining process conditions, high-nitrogenhigh-dry-point raw oil and hydrogen are mixed and enter a hydrofining reactor for a hydrofining reaction, the hydrofining reactor at least comprises two hydrofining catalyst beds, the upper portion ofeach hydrofining catalyst bed is filled with a hydrofining catalyst A, and the lower portion of each hydrofining catalyst bed is filled with a hydrofining catalyst B; (2) a hydrogenation reaction effluent obtained in the step (1) enters a hydrocracking reactor for a hydrocracking reaction, and the hydrocracking reactor is filled with a hydrocracking catalyst; and (3) a hydrocracking reaction effluent obtained in the step (2) enters a separation system to be separated to obtain one or more of gas, naphtha, aviation kerosene and diesel and tail oil.

Description

technical field [0001] The invention relates to a hydrocracking pretreatment method for high nitrogen and high dry point raw material oil, in particular to a hydrocracking method for high nitrogen and high dry point wax oil, and a method for producing high-quality products through hydrocracking. Background technique [0002] In modern oil refining technology, hydrocracking refers to those hydrogenation processes in which more than 10% of macromolecular compounds in raw materials are converted into small molecular compounds through hydrogenation reaction. It has strong adaptability to raw materials, great flexibility in production schemes, Good product quality and other characteristics, so it has become one of the important technologies for deep processing of heavy oil. The core of hydrocracking technology is catalyst, including pretreatment catalyst and cracking catalyst. Among them, the main function of the hydrocracking pretreatment catalyst is to remove impurities such a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10G65/12

CPCC10G65/12

Inventor 崔哲王仲义唐兆吉曹正凯孙士可

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com