A kind of preparation method of sulfur dye

A technology of sulfur dyes and sulfide bases, applied in sulfur dyes, chemical instruments and methods, dyeing methods, etc., can solve the problems of general blackness of cloth samples and poor decolorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

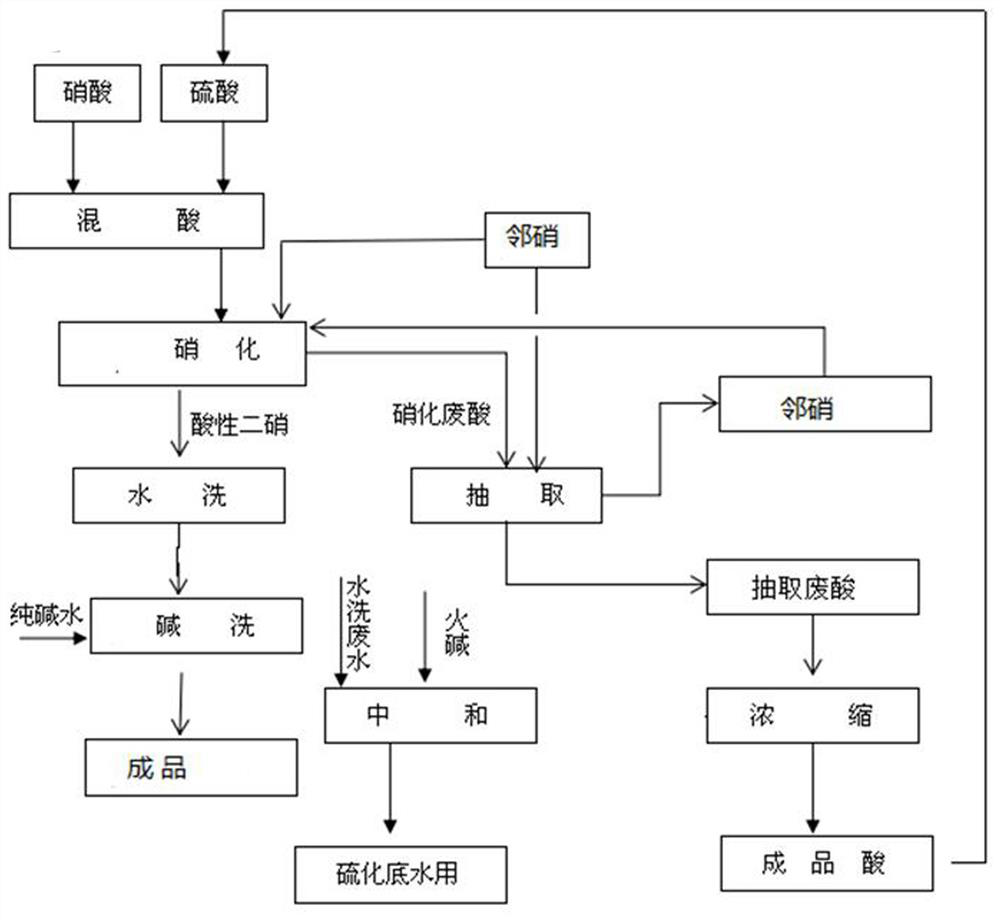

Method used

Image

Examples

Embodiment A1

[0027] Add 100g of o-nitrochlorobenzene into a 1000ml Erlenmeyer flask, heat it to a temperature of about 55°C in the observed pot, start stirring, and start to add 180g of mixed acid dropwise. The whole dropping process was controlled at 47±2°C. Add dropwise for about 1h and keep warm for 15 minutes. After the heat preservation is completed, it takes 1 hour to raise the temperature to about 100°C and keep the temperature for 3 hours. After the completion of the reaction, let stand for 40min and separate. The obtained product 2,4-dinitrochlorobenzene (DNCB) was 198g, with a purity of 90.23%, isomers of 9.77%, and a crystallization point of 44.8°C.

Embodiment A2

[0029] Add 100g of o-nitrochlorobenzene into a 1000ml Erlenmeyer flask, heat it to a temperature of about 55°C in the observed pot, start stirring, and start to add 180g of mixed acid dropwise. The whole dropping process was controlled at 47±2°C. Add dropwise for about 1h and keep warm for 15 minutes. After the heat preservation is completed, it takes 2 hours to raise the temperature to about 100°C and keep the temperature for 3 hours. After the completion of the reaction, let stand for 40min and separate. The obtained product DNCB was 190g, with a purity of 91.25%, an isomer of 8.75%, and a crystallization point of 44.1°C.

Embodiment A3

[0031] Add 100g of o-nitrochlorobenzene into a 1000ml Erlenmeyer flask, heat it to a temperature of about 55°C in the observed pot, start stirring, and start to add 180g of mixed acid dropwise. The whole dropping process was controlled at 47±2°C. Add dropwise for about 1h and keep warm for 15 minutes. After the heat preservation is completed, it takes 2.5 hours to raise the temperature to about 100°C and keep the temperature for 3 hours. After the completion of the reaction, let stand for 40min and separate. The obtained product DNCB was 195g, with a purity of 90.23%, an isomer of 9.77%, and a crystallization point of 44.9°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com