Technological method for separating and refining butyl butyrate by using partition plate tower

A technology of butyl butyrate and partition tower, which is applied in the technical field of separating and refining butyl butyrate by using partition tower, which can solve the difficulty of increasing the separation of butyl butyrate, affect the purity of butyl butyrate, increase the residence time, etc. problem, to achieve the effect of improving thermodynamic efficiency, low thermodynamic efficiency and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

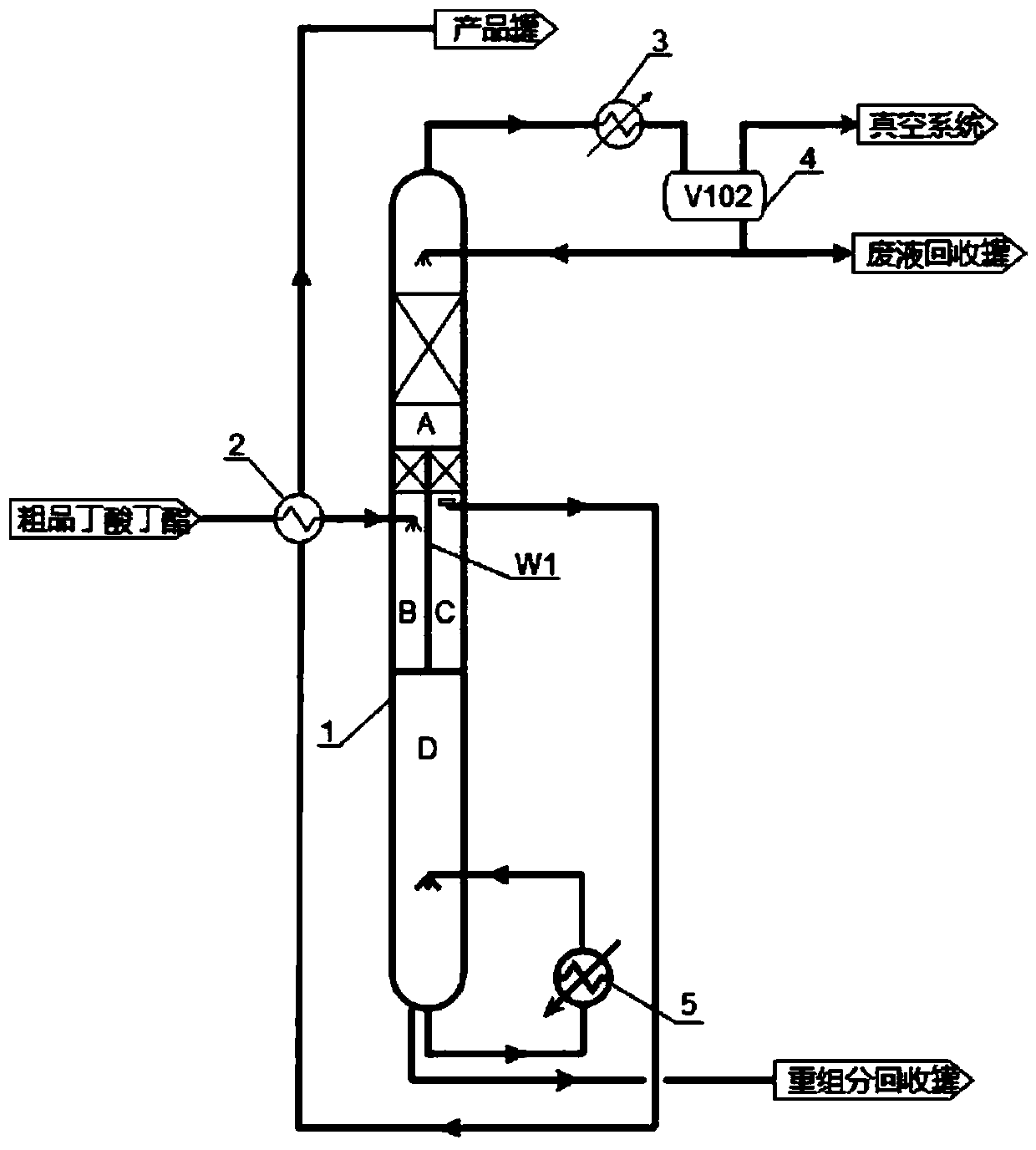

[0037] Example 1: the mass concentration of butyl butyrate in the crude product butyl butyrate is 93%, the feed rate is 15L / h, the number of theoretical plates in the public rectification section is 12, and the number of theoretical plates in the pre-fractionation section and the main column is 8 , the number of theoretical plates in the common stripping section is 5, the feed position is at the second theoretical plate in the pre-fractionation section of the partition tower, the reflux ratio is 6, and the distribution ratio of the reflux liquid between the feed section on both sides of the partition and the side line outlet section is 3. The operating pressure at the top of the partition tower is -73kPa, and the operating temperature at the top of the tower is 111°C. The overhead fraction is condensed and enters the reflux tank, and analyzed by gas chromatography, the mass concentration of n-butyraldehyde is 50.4%, the mass concentration of n-butanol is 6.8%, and the mass conc...

example 2

[0039] Example 2: Butyrate mass concentration is 89% in the crude product butyl butyrate, feed rate is 19L / h, and public rectifying section theoretical plate number is 15, and pre-fractionation section and main column theoretical plate number are 11, The number of theoretical plates in the common stripping section is 8, the feed position is at the sixth theoretical plate in the pre-fractionation section of the partition tower, the reflux ratio is 9, and the distribution ratio of the reflux liquid between the feed section on both sides of the partition and the side line discharge section is 5, The operating pressure at the top of the partition column is -81kPa, and the operating temperature at the top of the column is 108°C. The overhead fraction is condensed and enters the reflux tank. After chromatographic analysis, the mass concentration of n-butyraldehyde is 53.6%, the mass concentration of n-butanol is 6.3%, and the mass concentration of isobutyraldehyde is 10.5%. The buty...

example 3

[0040] Example 3: the mass concentration of butyl butyrate in the crude product butyl butyrate is 85%, the feed rate is 20L / h, the number of theoretical plates in the public rectification section is 18, and the number of theoretical plates in the pre-fractionation section and the main column is 14 , the number of theoretical plates in the common stripping section is 11, the feed position is at the 10th theoretical plate in the pre-fractionation section of the partition tower, the reflux ratio is 3, and the distribution ratio of the reflux liquid in the feed section on both sides of the partition and the side line discharge section is 7. The operating pressure at the top of the partition tower is -77kPa, and the operating temperature at the top of the tower is 114°C. The overhead fraction is condensed and enters the reflux tank. After chromatographic analysis, the mass concentration of n-butyraldehyde is 56.4%, the mass concentration of n-butanol is 6.9%, and the mass concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com