Gypsum-based self-leveling material as well as application and application method thereof in artware

A self-leveling, gypsum-based technology, applied in the field of building materials, can solve problems such as aggravating the greenhouse effect, soil erosion, and easy breakage, and achieve the effects of realizing environmental protection value, improving fluidity, and improving water retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

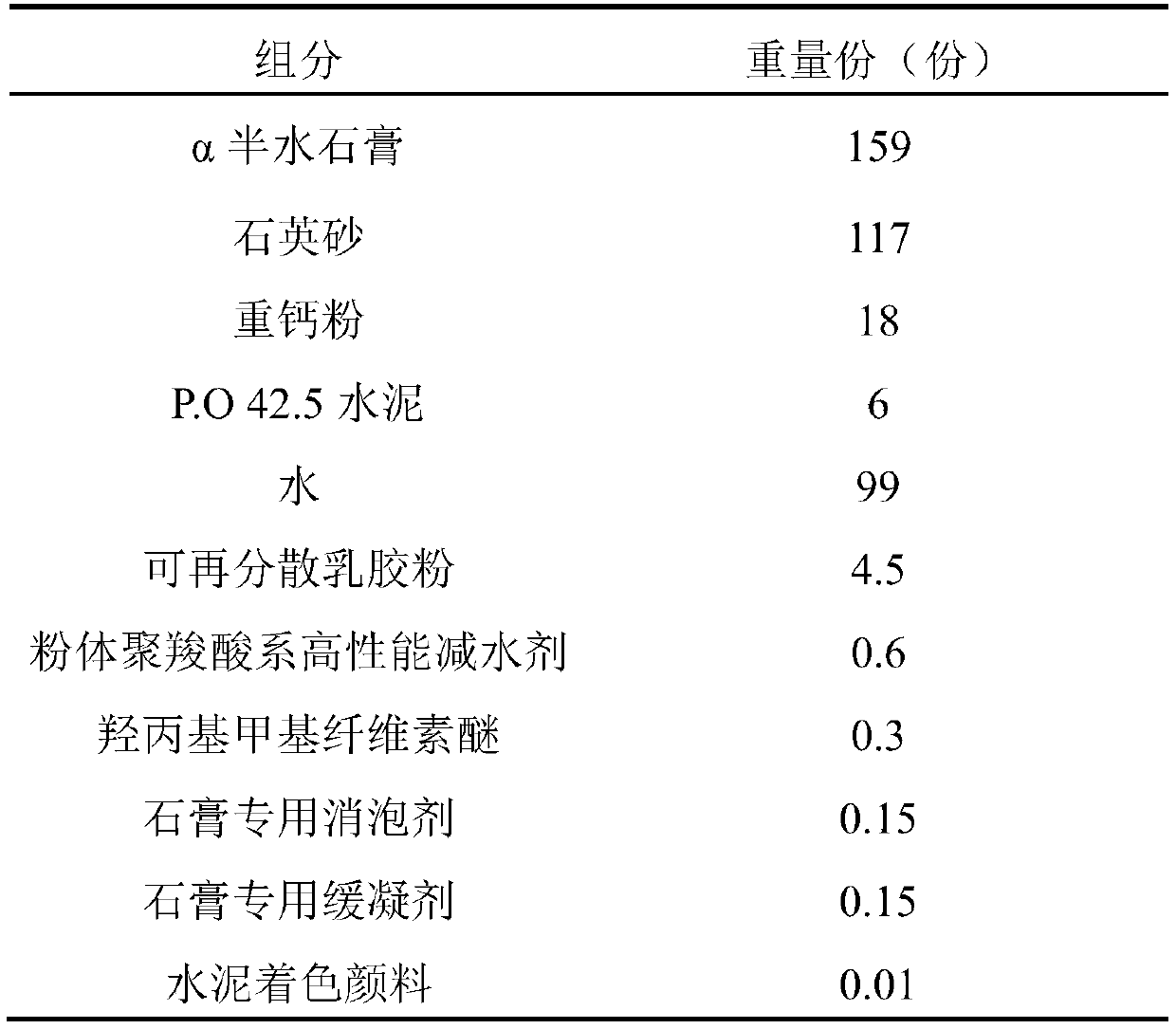

[0035] Weigh the required components according to the parts by weight of the gypsum-based self-leveling material shown in Table 1.

[0036] The composition ratio of table 1 embodiment 1

[0037]

[0038] Mix the weighed solid components evenly and place them in the cement mortar mixing pot, then mix the weighed liquid components evenly and add them to the mixing pot where the solid components are placed, start the cement mortar mixer, and stir for 2 -4min to form a self-leveling slurry, and then pour the evenly stirred self-leveling slurry into the customized chess latex mold or other handicraft molds (such as pen holder molds, animation character model molds, etc.) three times, after each pouring Stir and tamp with a glass rod several times to remove the air bubbles attached to the inner wall of the mold as much as possible after pouring the slurry. After pouring, scrape off the excess slurry with a scraper and smooth it, and let it stand at room temperature for 24 hours. ...

Embodiment 2

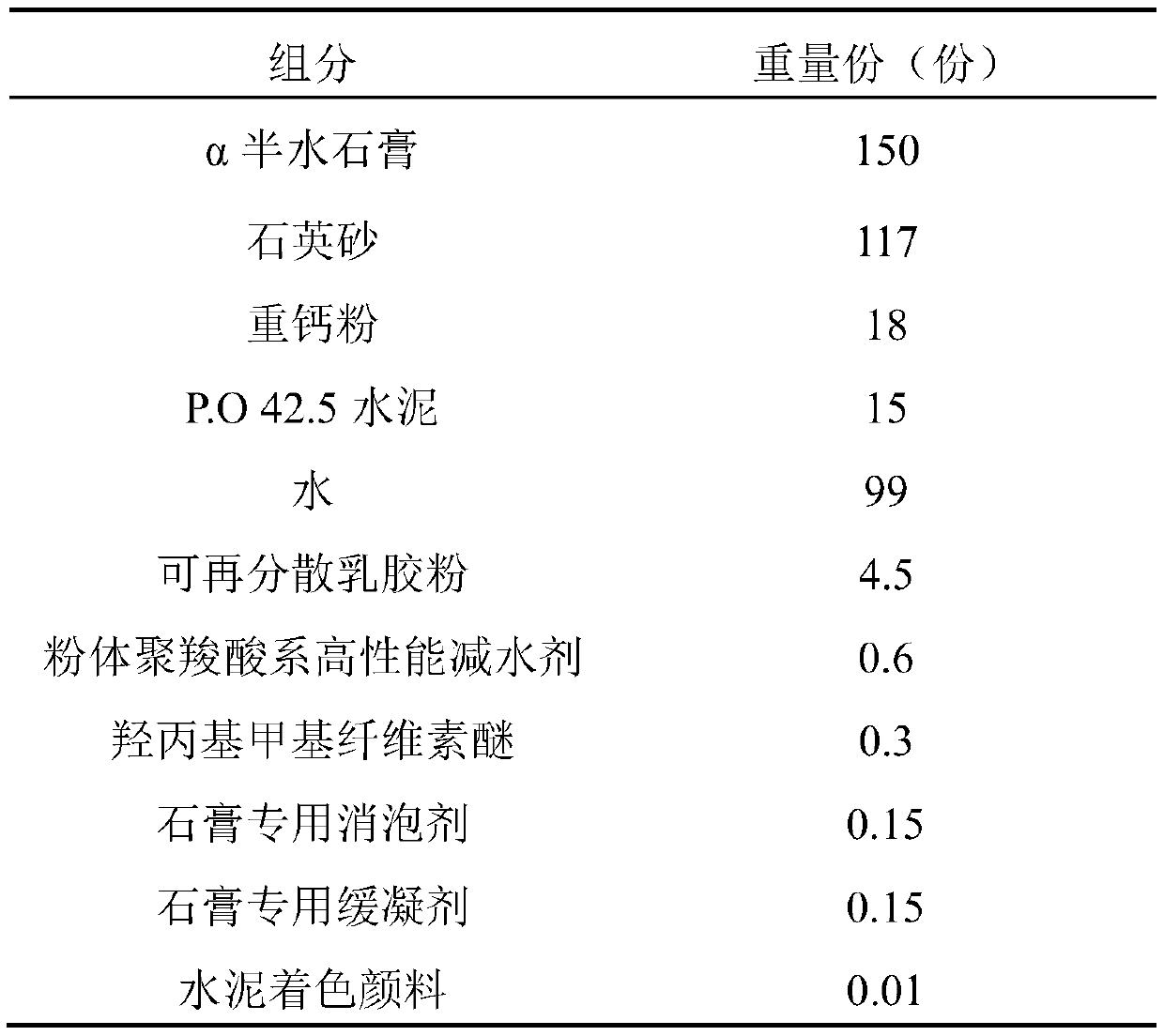

[0042] Weigh the required components according to the parts by weight of the gypsum-based self-leveling material shown in Table 2.

[0043] The composition ratio of table 2 embodiment 2

[0044]

[0045] The steps of the rest of the manufacturing method are substantially the same as in Example 1.

[0046] For handicrafts such as chess made by using the formula of this example, the initial setting time of the self-leveling slurry material is 15 minutes, the final setting time is 38 minutes, the 7d dry compressive strength of the material can reach 13.2MPa, and the scratch hardness is 0.21mm. The wear resistance is about 13.7%, and the impermeability grade is P6. The handicrafts such as chess made have brighter color, better wear resistance, less surface burrs, and are not easy to drop powder.

Embodiment 3

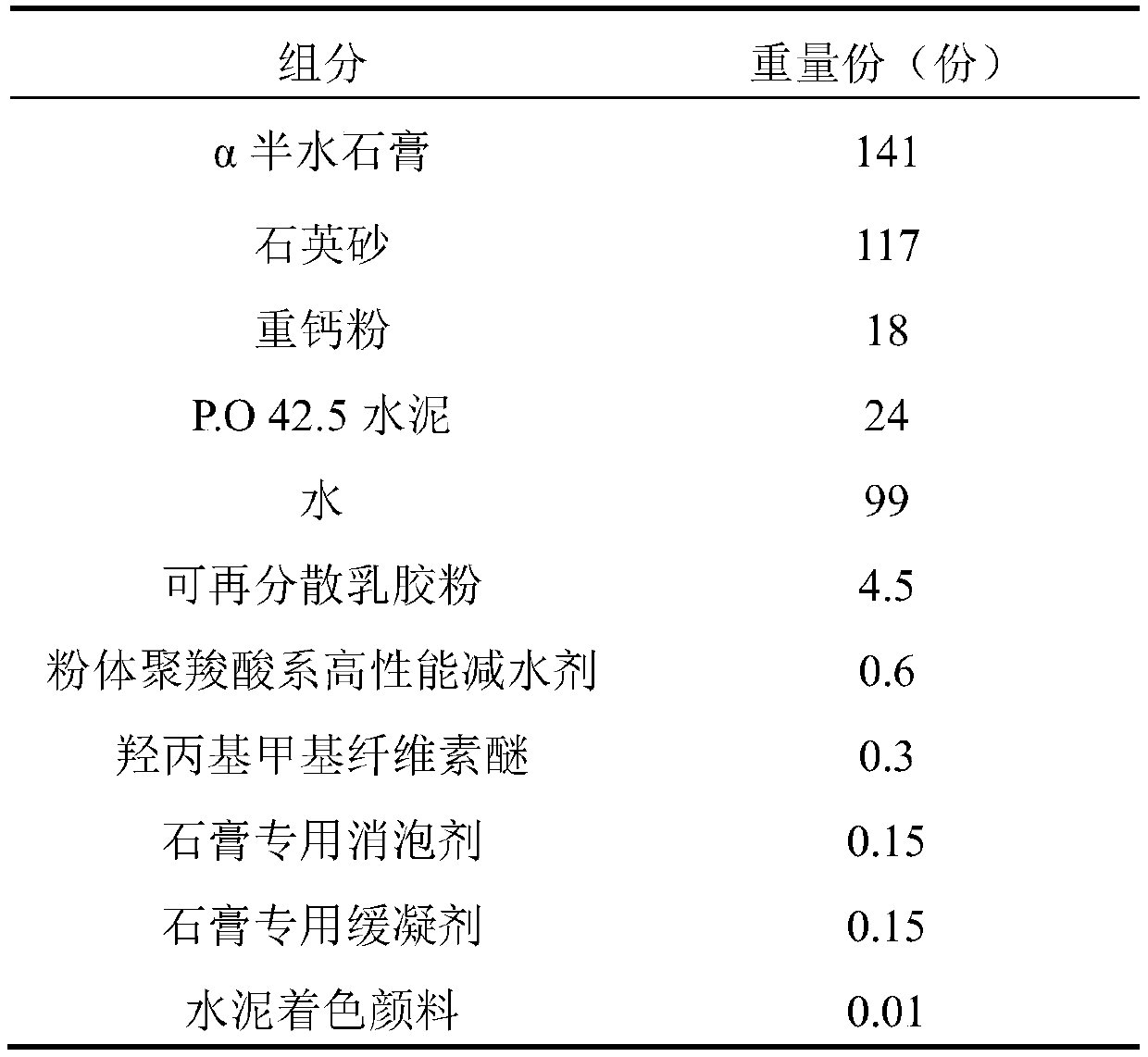

[0048] Weigh the required components according to the parts by weight of the gypsum-based self-leveling material shown in Table 3.

[0049] The composition ratio of table 3 embodiment 3

[0050]

[0051] The steps of the rest of the manufacturing method are substantially the same as in Example 1.

[0052] For handicrafts such as chess made by using the formula of this example, the initial setting time of the self-leveling slurry material is 14 minutes, the final setting time is 35 minutes, the 7d dry compressive strength of the material can be as high as 15.7 MPa, and the scratch hardness is about 0.15 mm , the wear resistance is about 11.4%, and the impermeability level is P6. In addition, due to the large amount of cement, the handicrafts such as chess made are slightly darker in color than those in Example 1 and Example 2, but they have good wear resistance and are not easy to drop powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry compressive strength | aaaaa | aaaaa |

| Dry compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com