Algae-based biological phosphorus removal water purifying agent and preparation method thereof

A phosphorus water purifying agent and biological technology, applied in the field of nano-diatom composite water purifying agent and its preparation, can solve the problems of obstruction, adsorption site occupation, limitation of diatomite adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of nano-diatom composite water purifying agent, comprising the following steps:

[0022] (1) The natural diatom mineral powder is mechanically ground, and passed through a 80-100 mesh sieve, and the diatomite obtained after passing through the sieve is roasted at a temperature of 650° C. for 80 minutes, and then cooled to room temperature;

[0023] (2) The diatomite obtained in step (1) is added according to the ratio of adding 5 mL of nitric acid solution with a concentration of 0.6 mol / L per gram of diatomite, and configured as required, and the above solution is placed in a suitable container and put into In a constant temperature water bath oscillator, the temperature of the water bath is 40°C, and the shaking time is 1.5h. After the end, filter, wash the filter residue with deionized water until it is neutral, dry it in vacuum at 85°C for 6-8h, and then cool to room temperature. The obtained diatomite is mechanically ground again, and passed th...

Embodiment 2

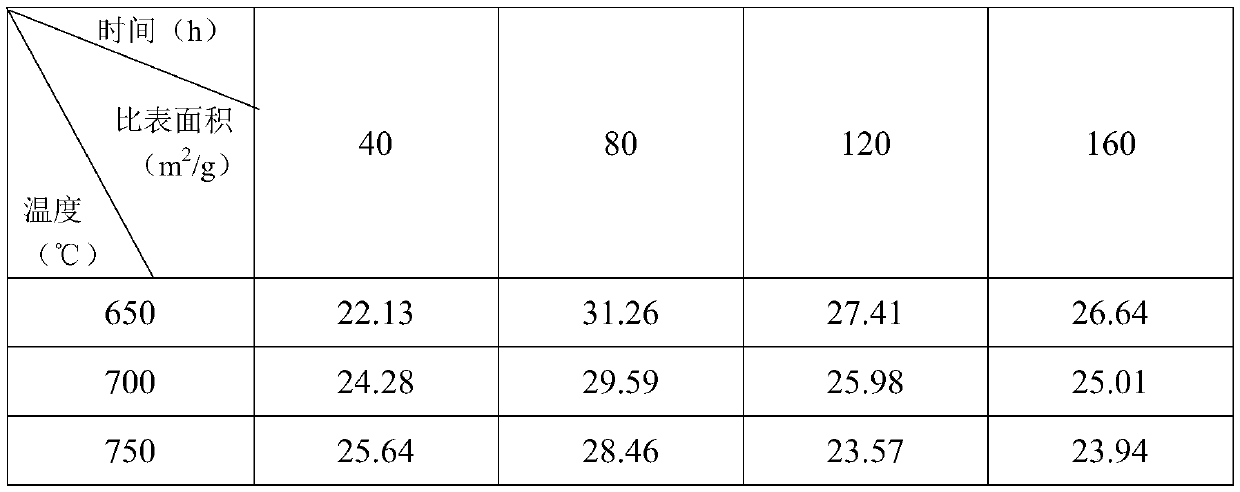

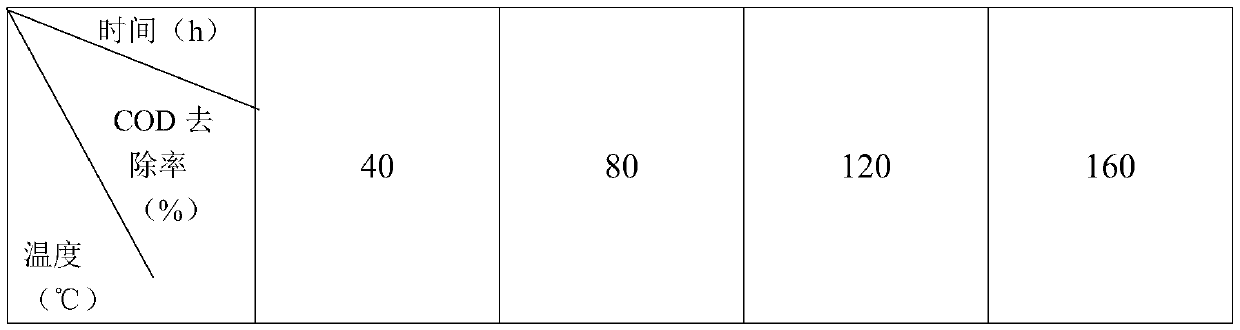

[0026] In order to screen out the optimal calcination temperature and time of diatomite, the effects of different calcination temperatures and time treatments on the specific surface area and water purification capacity of diatomite were explored.

[0027] Firstly, the calcination temperature and calcination time were screened by orthogonal test, and the specific surface area of untreated natural diatomite was compared. Under the calcination temperature and time conditions of each group, 20g of natural diatomite was taken for treatment, washed with deionized water, then vacuum-dried at 80°C for 6 hours and then cooled to room temperature, and the ratio of diatomite after each group of treatment was measured. surface area. The results are shown in Table 1.

[0028] Table 1 Effects of different calcination temperatures and times on the specific surface area of diatomite

[0029]

[0030] The specific surface area of untreated natural diatomaceous earth is 16.56m 2 / g...

Embodiment 3

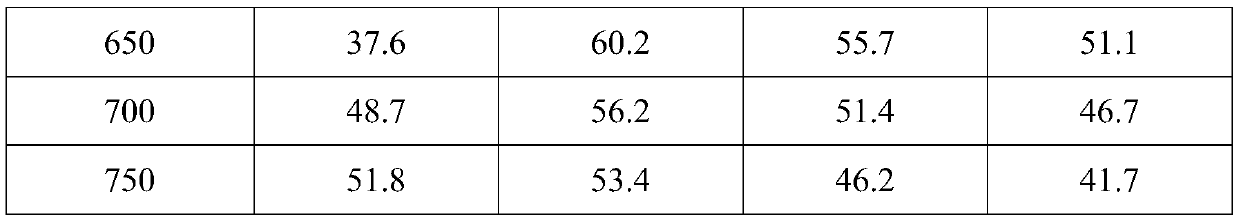

[0037] In order to screen out the optimal concentration of nitric acid solution, the effects of different concentrations of nitric acid solution treatment on the specific surface area and water purification capacity of diatomite were explored.

[0038]The natural diatomite is divided into 5 groups by equal weight, numbered as 1-5 groups, 1-5 groups are respectively natural group, roasting group, low concentration acid treatment group (0.2mol / L), medium concentration acid treatment group (0.4mol / L) / L), high concentration acid treatment group (0.6 mol / L). Among them, groups 2-4 of diatomite were roasted at 650°C for 80 minutes, and then groups 3-5 were acid-leached in nitric acid solutions with concentrations of 0.2mol / L, 0.4mol / L, and 0.6mol / L. . The treatment method is: add 5 mL of nitric acid solution with a concentration of 0.6 mol / L per gram of diatomaceous earth, configure according to the needs, put the above solution in a suitable container and put it in a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com