Preparation method and application of manganese oxide hollow fibers

A manganese oxide and hollow technology, applied in manganese oxide/manganese hydroxide and other directions, can solve the problems of insufficient environmental protection, long time consumption, etc., and achieve the effect of simple preparation method and easy large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

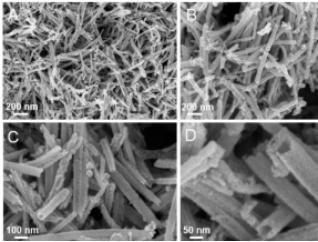

Image

Examples

preparation example Construction

[0026] A kind of preparation method of manganese oxide hollow fiber, comprises the following steps in sequence:

[0027] The first step is to weigh an appropriate amount of manganese acetylacetonate and disperse it in glycerol to obtain a uniform black solution;

[0028] In the second step, add an appropriate amount of Te nanowires to the black solution in the first step, continue to stir evenly, and then transfer it to the heating reaction device;

[0029] In the third step, the mixed solution obtained in the second step is heated up to 210°C at a heating rate of 3°C / min in the heating reaction equipment, and then the heating is stopped, and the temperature is kept at this temperature for 30min, and the stirring speed of the magnet is set to 50°C. -80rpm;

[0030] In the fourth step, the reaction product obtained in the third step is washed with a mixed solution of deionized water and ethanol. After washing three times, it is dispersed in a 2M NaOH solution and transferred t...

Embodiment 1

[0032] Take by weighing 0.1g manganese acetylacetonate and disperse it in 40mL of glycerol, obtain a black solution after dispersing evenly, then transfer it to a three-necked flask and add 10mg of washed Te nanowires to continue stirring and dispersing until completely dispersed, to obtain The black solution has a silky shape visible to the naked eye, and then transferred to the heating device, and the heating rate was set to 3°C / min from room temperature to 210°C, and then kept at this temperature for 30min after the temperature was raised to 210°C. The rotating speed of the shape magnet is 55rpm. After the end, wash the reaction solution with a mixed solution of ethanol and deionized water, and then redisperse it in 2M sodium hydroxide solution and react it in a hydrothermal reactor at 150°C for 2 hours to obtain the final product — Manganese oxide hollow fibers.

Embodiment 2

[0034] Take by weighing 0.1g manganese acetylacetonate and disperse it in 40mL of glycerol, obtain a black solution after dispersing evenly, then transfer it to a three-necked flask and add 10mg of washed Te nanowires to continue stirring and dispersing until completely dispersed, to obtain The black solution has a silky shape visible to the naked eye, and then transferred to the heating device, and the heating rate was set to 3°C / min from room temperature to 210°C, and then kept at this temperature for 30min after the temperature was raised to 210°C. The rotating speed of the shape magnet is 55rpm. After the end, wash the reaction solution with a mixed solution of ethanol and deionized water, and then redisperse it in 2M sodium hydroxide solution and react it in a hydrothermal reactor at 180°C for 65 minutes to obtain the final product — Manganese oxide hollow fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com