LCD screen buffering shock-proof rubber protecting jacket capable of being quickly assembled and disassembled

A technology of LCD screen and rubber sleeve, applied in packaging, transportation and packaging, closing and other directions, can solve the problems of difficult to guarantee the quality of assembly, long assembly time, hidden danger of product quality, etc., and achieve the improvement of product quality, efficiency and improvement. The effect of production and assembly efficiency and structural detail optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

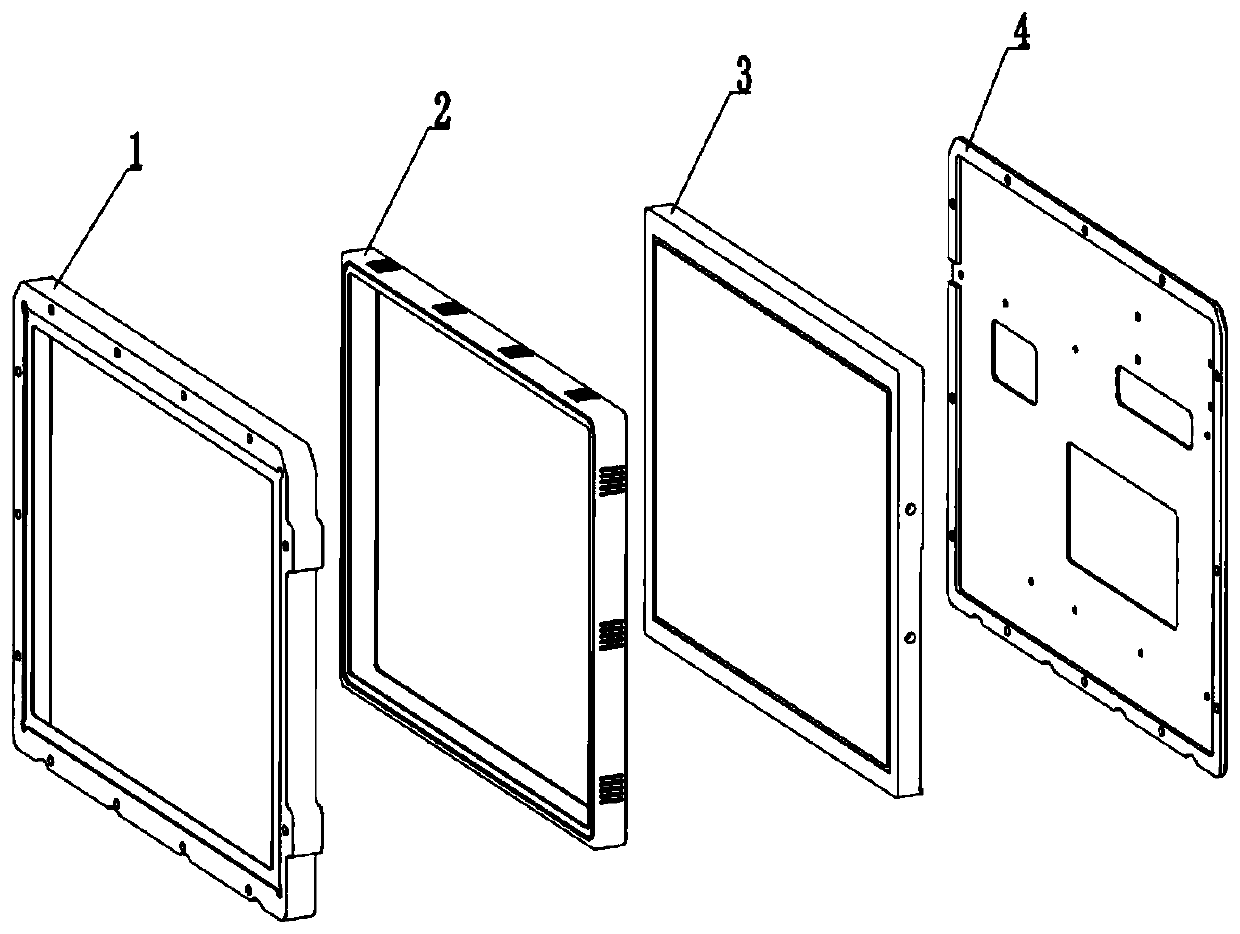

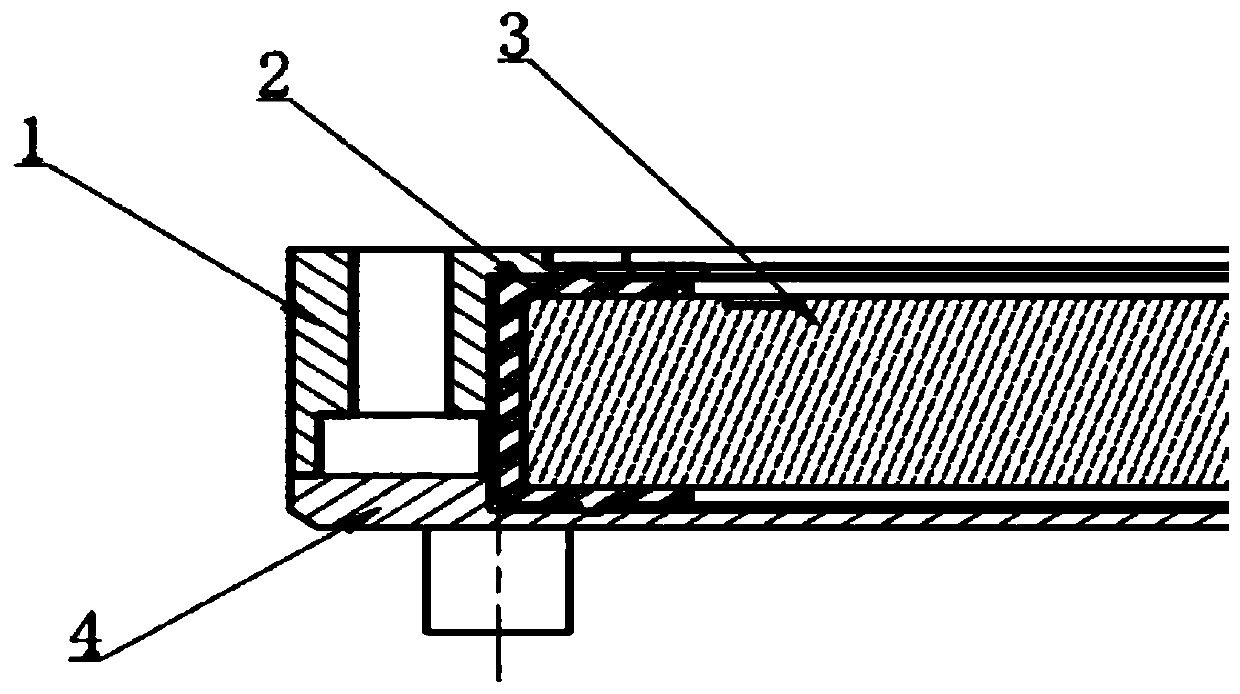

[0027] Such as figure 1 As shown, the entire structure is divided into four parts, which are terminal front cover 1, rubber cover 2, display screen 3, and display screen pressure plate 4. Among them, the terminal front cover 1 is mainly used here to indicate the installation position of the display screen, and is not limited to this structural shape. Its main feature is that there is a concave inner cavity inside, which can be found in figure 2 .

[0028] Such as figure 2 As shown, the display screen 3 is nested in the serial number rubber sleeve 2. After the nesting is completed, the two pieces are installed inside the front cover 1 of the terminal, and finally the display screen pressure plate 4 is used to press and fix it; The cover 1 is fixed by screw connection.

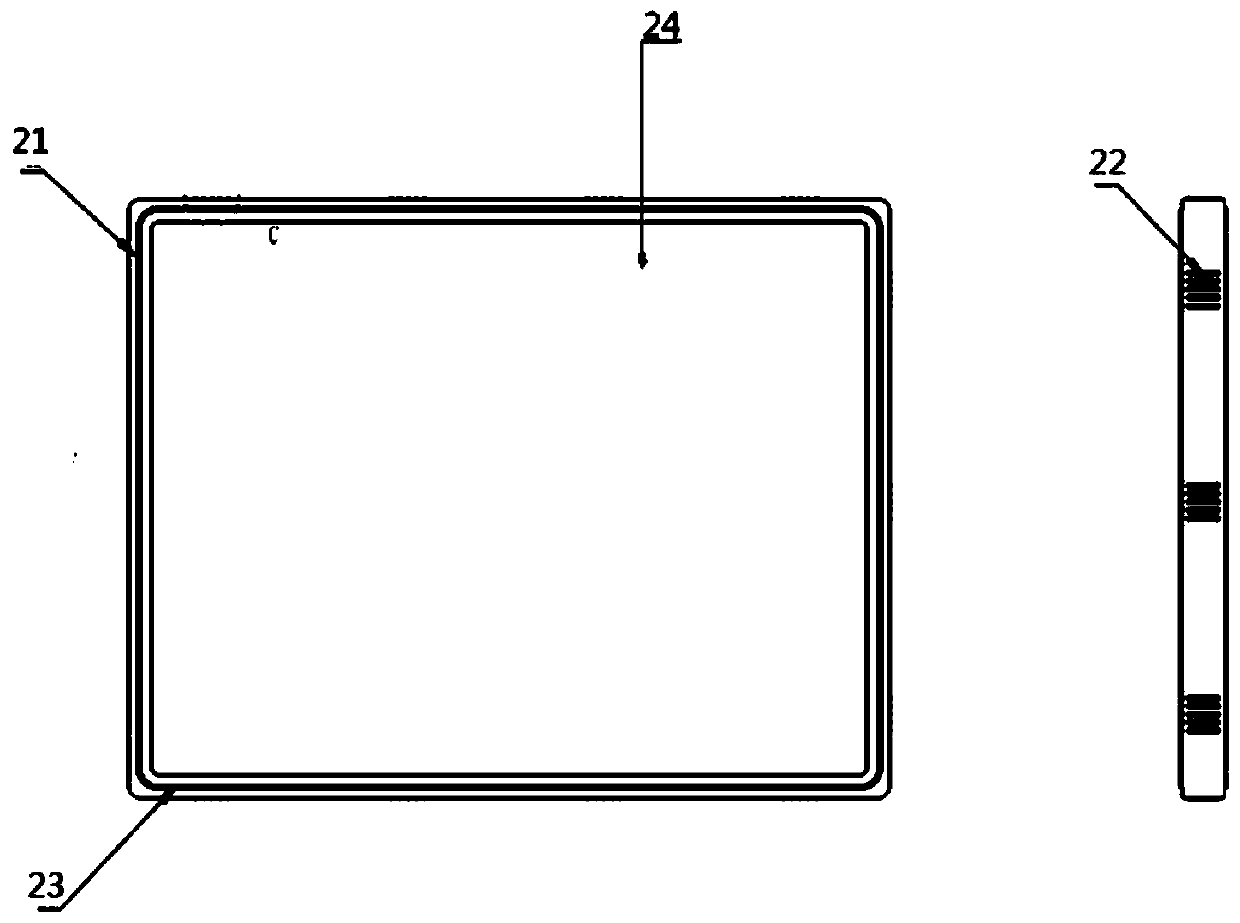

[0029] Such as image 3 Shown is the detailed structure diagram of the serial number rubber sleeve 2. The rubber sleeve is made of silicone rubber material, because it has excellent high and low temperatur...

Embodiment 2

[0031] Such as image 3 Shown, anti-slip protrusion 22 has two effects:

[0032] 1. In terms of its single shape, after the installation of the overall structure is completed, the anti-skid protrusion 22 and figure 2 The side wall of the terminal front cover 1 in the terminal will generate rebound force and friction force after contact deformation, so that figure 2 The position of the middle display screen 3 can be fixed;

[0033] 2. From the point of view of its distribution pattern on each side of the rubber sleeve 2, the five anti-skid protrusions 22 form a group, and several groups are evenly distributed on each side of the rubber sleeve 2 according to the actual length, and the distance between each group should not Less than 50mm. combine figure 2 , the purpose of this design is that if the inner cavity of the front cover 1 of the terminal is at the minimum physical limit and the rubber sleeve 2 and the display screen 3 are at the maximum physical limit due to pro...

Embodiment 3

[0038] Such as figure 1 , figure 2 As shown, the display screen 3 is nested into the rubber sleeve 2 during assembly, and then installed inside the terminal front cover 1 after the nesting is completed, and finally the display pressure plate 4 is screwed to the terminal front cover 1 to achieve compression and fixation Among them, the rubber sleeve 2 has a symmetrical layout, and there is no need to distinguish the front and back sides during the assembly process, which can further improve the assembly efficiency.

[0039] Such as figure 2 As shown, the display screen 3 is nested in the rubber sleeve 2, between the display screen 3 and the front cover 1 of the terminal, and between the display screen 3 and the display pressure plate 4, a buffer and shock absorbing layer is formed with the rubber sleeve 2 acting as an isolation ;In the face of impact and vibration, the excellent cushioning and shock absorbing properties of silicone rubber play a good role in protecting the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com