PTFE resin composition

A resin composition, polytetrafluoroethylene technology, used in mechanical equipment, engine components, engine sealing and other directions, can solve the problem of poor lubricity, inability to prevent carbon fiber from falling off, deformation resistance (pressure resistance, wear resistance and sealing) Unsatisfactory performance, etc., to achieve the effect of excellent sealing performance, satisfying sealing performance and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

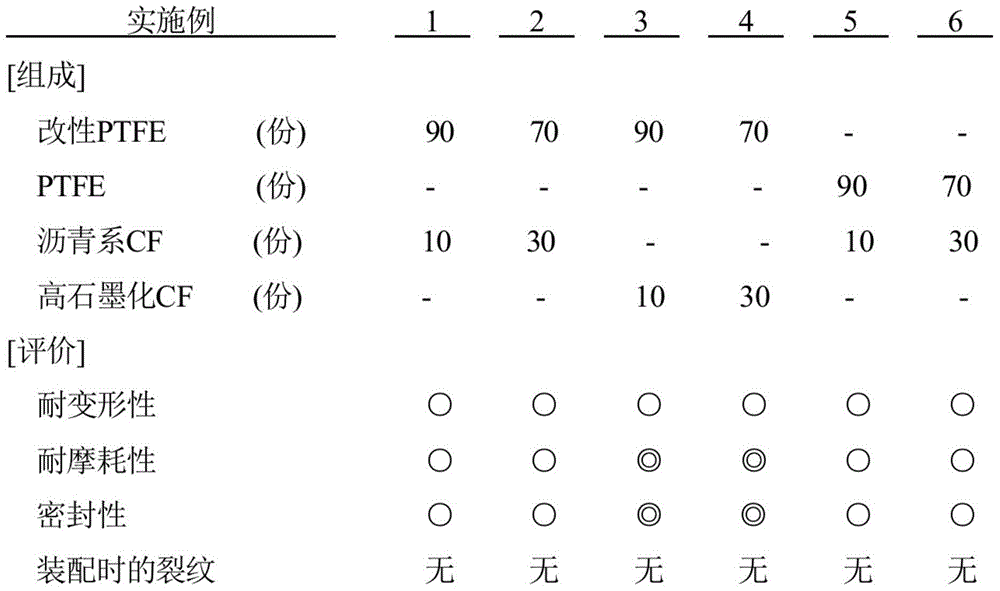

[0034] 90 parts (by weight; the same below) of modified PTFE (Teflon (registered trademark) 70-J, manufactured by Mitsui Dupont Fluoro Chemical; modified PTFE) and pitch-based curved carbon fibers (average fiber diameter 13 μm, average fiber length 90 μm, radius of curvature 517 μm) 10 parts are compounded by the above method, and then compression molded at about 60 to 70 MPa using a press or the like, and fired at 360 to 390° C. for 3 hours in a firing furnace.

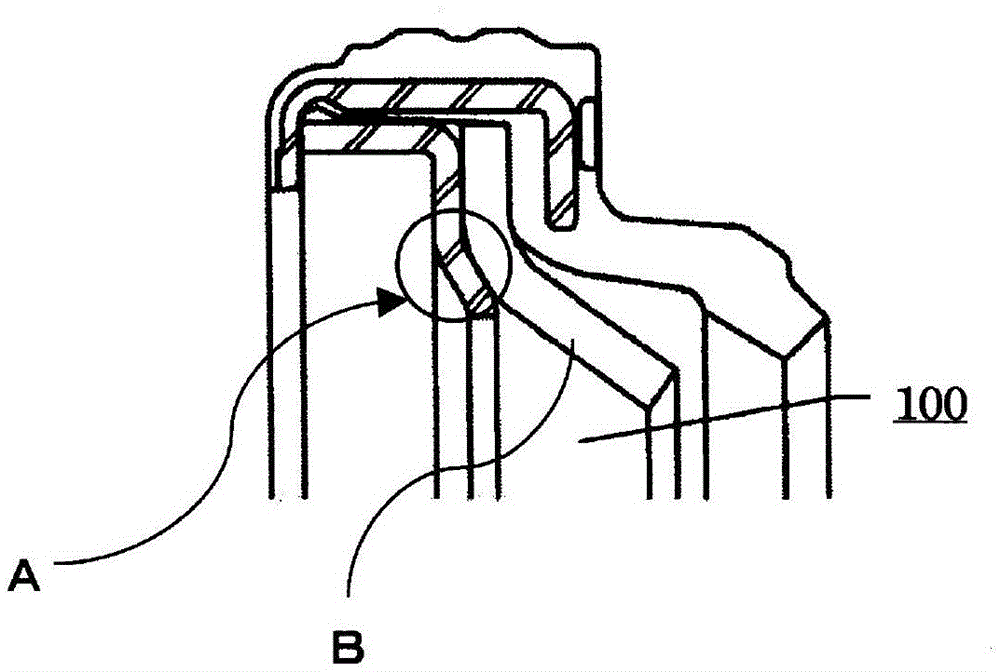

[0035] Then, a lip seal as shown in the figure was fabricated by cutting, and the seal was operated for 1000 hours to conduct a sealing performance evaluation test. Product evaluation was performed according to the following criteria.

[0036] Deformation resistance:

[0037] The state of the lip after the test was visually observed. On the portion (waist A) where the sealing liquid side was bent on the inner diameter side of the lip seal 100, the case where no deformation was found was marked as ○, and the case whe...

Embodiment 2

[0045] In Example 1, the amount of modified PTFE was changed to 70 parts, and the amount of pitch-based curved carbon fiber was changed to 30 parts.

Embodiment 3

[0047] In Example 1, instead of pitch-based curved carbon fibers, highly graphitized pitch-based curved carbon fibers (average fiber diameter 13 μm, average fiber length 90 μm, radius of curvature 484 μm) were used in the same amount.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com