Dust suction device for stone machining

A dust collection device and stone processing technology, applied in stone processing equipment, processing models, decorative art, etc., can solve the problems of internal blockage, a large amount of dust, and ingress of the device, so as to facilitate collection, reduce friction, and speed up flow speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

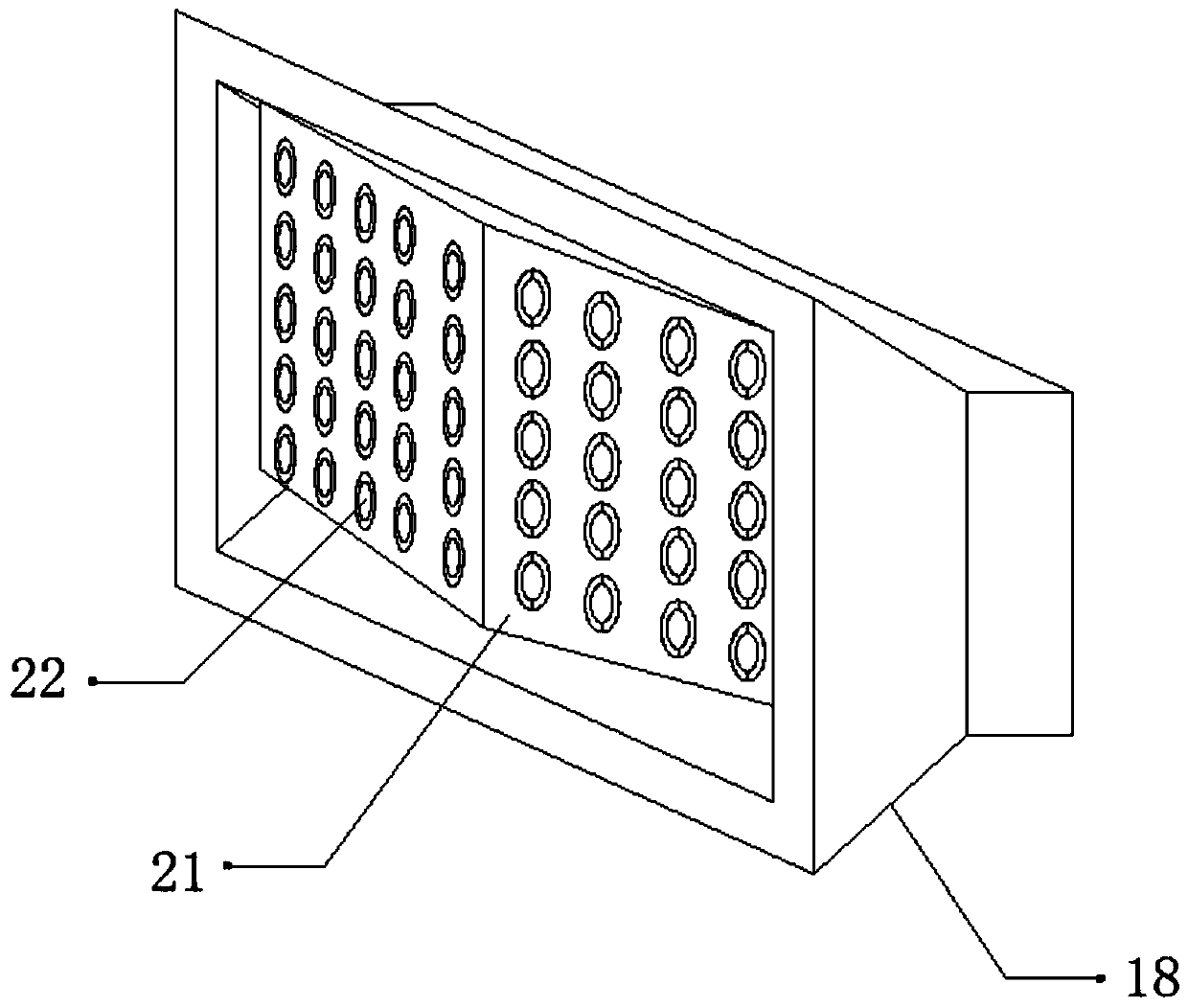

[0029] refer to Figure 1-3 , a dust collection device for stone processing, comprising a fixed seat 1, the four corners of the top outer wall of the fixed seat 1 are connected with a spring 4 by bolts, and the top outer wall of the spring 4 is connected with a dust collection box 5 by bolts, the top of the fixed seat 1 The outer wall is connected with the impact block 2 by bolts, and the outer wall of one side of the dust collection box 5 is provided with a dust inlet, and the inner wall of the dust inlet is connected with a dust inlet pipe 17 by bolts, and the outer wall of one side of the dust inlet pipe 17 is connected by a flange. Fan 19 is arranged, and one side outer wall of fan 19 is provided with air duct 20, and one side outer wall of air duct 20 is connected with dust collection cover 18 by bolt, and the inwall of dust collection cover 18 is connected with splitter plate 21 by bolt, splitter plate The outer walls on both sides of 21 are provided with a plurality of ...

Embodiment 2

[0040] refer to Figure 4 , a dust collection device for stone processing. Compared with Embodiment 1, the inner wall of the collection box 6 is connected with a filter screen 24 through hinges in this embodiment, which can purify the dust.

[0041]Working principle: When in use, move the device to a suitable position through the moving wheel 3 and the push rod 9, start the fan 19, the fan 19 will absorb the dust into the interior of the dust collection hood 18, and the dust will enter the interior of the dust inlet 22 , so as to enter the inside of the dust collection box 5 through the dust inlet pipe 17, inject an appropriate amount of water into the inside of the water tank 12 through the water inlet, and deliver the water to the inside of the catheter tube 10 through the drain pipe 13 and the solenoid valve 14, thereby passing The atomizing nozzle 15 sprays out the water mist so that the dust can be dust-reduced. The dust will enter the inside of the collection box 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com