Steel wire twisting mechanism for steel wire rust removing machine

A derusting machine and steel wire technology, which is applied to the parts of grinding machine tools, grinding racks, devices for fixing grinding wheels, etc., can solve the problems of unclean treatment, small friction, and dead angle of rust removal, etc., and achieve flexible rotation, Effect of reducing frictional resistance and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be described in detail below in conjunction with the drawings. In this embodiment, front and back are defined by the direction of wire travel, and the sides of the direction of wire travel are defined as left and right. The side close to the wire is defined as the inner side, and the side far from the wire is defined as the outer side.

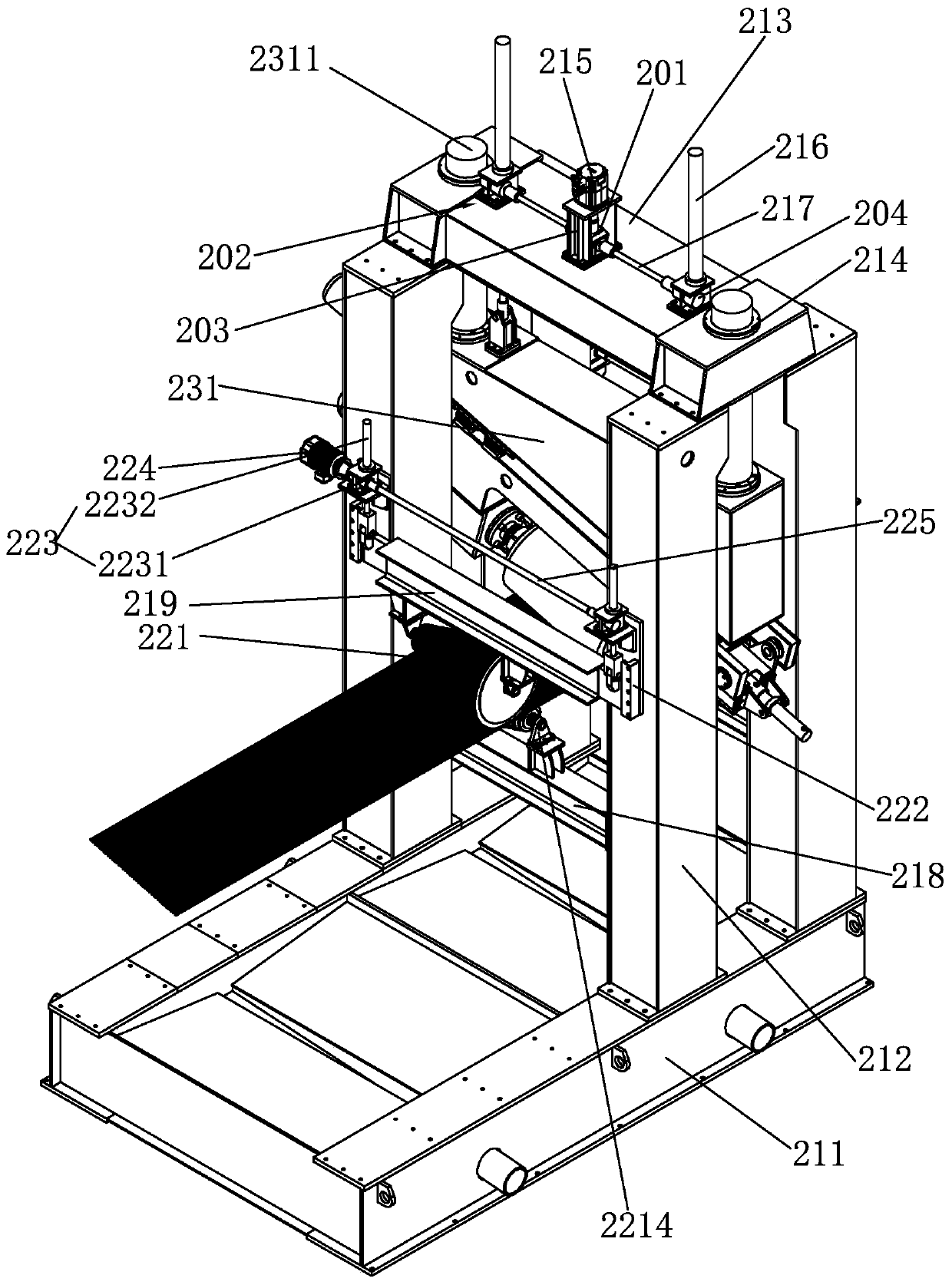

[0040] Such as Figure 1 ~ Figure 6 As shown, the steel wire rust removing machine includes a rust removing frame 21, a steel wire torsion mechanism 22, and a steel wire rust removing mechanism 23. There are two steel wire torsion mechanisms 22, and the two steel wire torsion mechanisms 22 are respectively arranged in the rust removing frame 21. At the steel wire entrance and the steel wire exit, the steel wire rust removing mechanism 23 is arranged between the two steel wire torsion mechanisms 22 on the rust removing frame 21.

[0041] Such as Figure 1 ~ Figure 6 As shown, the derustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com