Multi-electrode welding device and method for metal shielding layer of submarine cable

A metal shielding layer and welding device technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problem of insufficient metallurgical reaction of single-electrode welding seam, short continuous welding time of single-electrode TIG welding, affecting the stable use of electrodes It can improve the metallurgical reaction of the molten pool, increase the continuous use time, and reduce the risk of welding accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

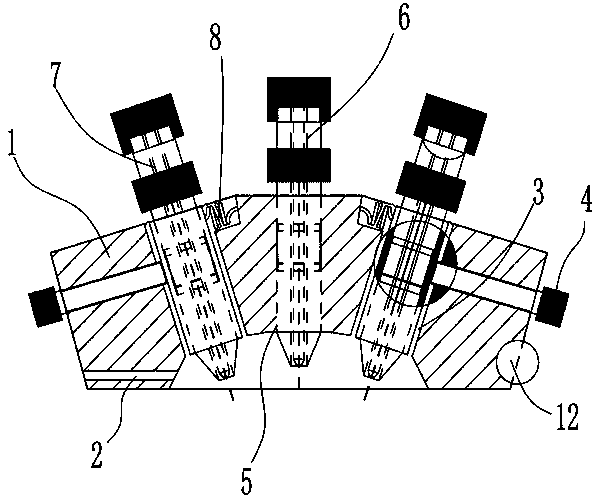

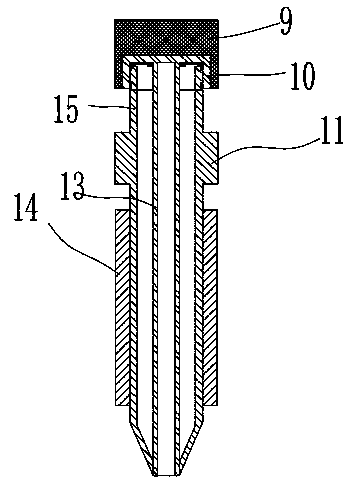

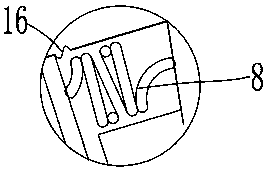

[0028] Embodiment: A multi-electrode welding device for the metal shielding layer of a submarine cable, including a mounting plate 1, a central electrode assembly 6 vertically arranged in the center of the mounting plate 1, and side electrode assemblies distributed in a circular array around the central electrode assembly 6 7. An electrode deflection angle adjustment mechanism is provided between the side electrode assembly 7 and the mounting plate 1. The side electrode assembly 7 and the center electrode assembly 6 have the same structure and are equipped with an electrode height adjustment mechanism.

[0029] In the above design, multiple electrode assemblies work together to improve arc stability and reduce the risk of welding accidents; multi-electrode shunt, reduce electrode temperature, reduce the burning rate of tungsten needles, greatly increase the continuous use time of tungsten needles, and increase production capacity; through Welding preheating improves the metallu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com