Steady casting technique for inhibiting liquid level fluctuation of continuous casting crystallizer

A continuous casting crystallizer and liquid level fluctuation technology, which is applied in the field of continuous casting technology in the metallurgical industry, can solve the problems of complex reasons for continuous casting crystallizer liquid level fluctuations, inaccessibility, good and bad time for crystallizer liquid level fluctuations, etc., to achieve Reduce mold flux poor lubrication, eliminate resonance, and improve surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the implementation cases of the present invention clearer, the following will make a clear and complete description of the technical solutions in the implementation cases of the present invention in conjunction with the drawings in the implementation cases. Obviously, the stated implementation cases are A small part of the implementation cases of the present invention, not all implementation cases, based on the implementation cases of the present invention, all other implementation cases obtained by those of ordinary skill in the art without creative work, fall within the scope of protection of the present invention .

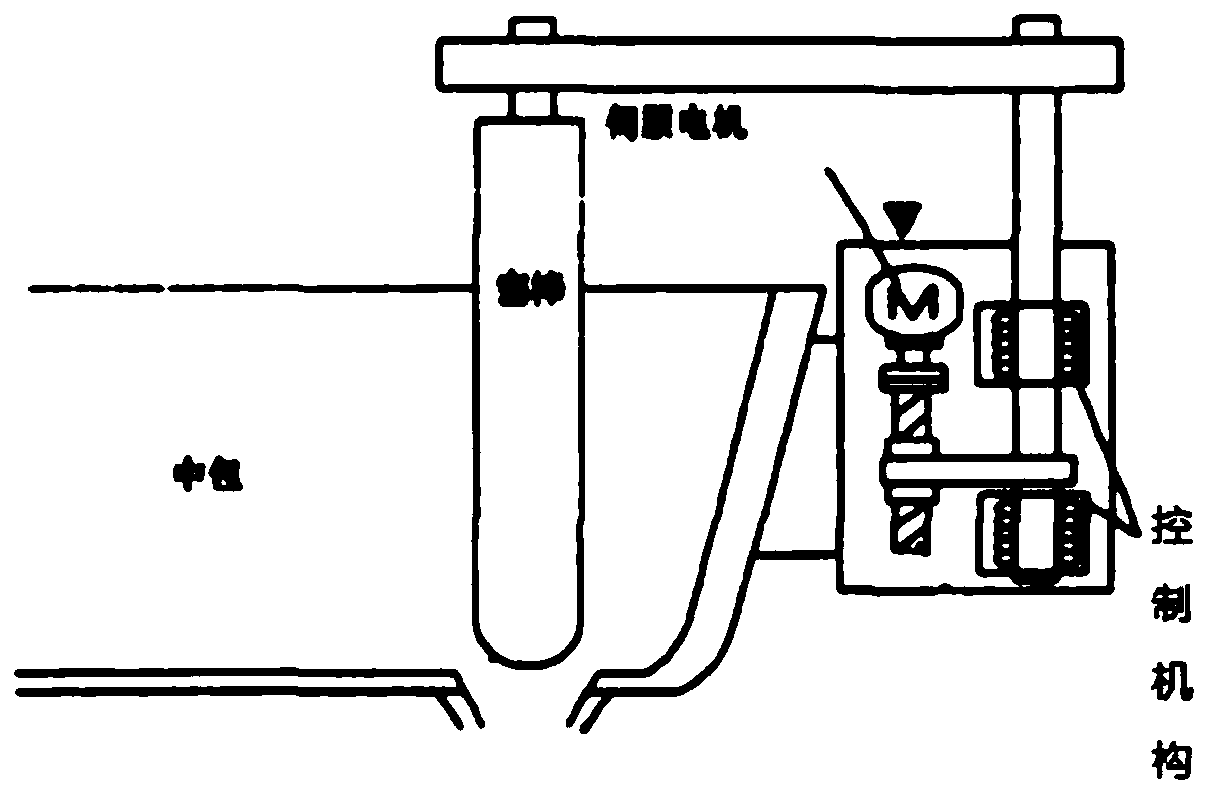

[0015] A steady-state casting process method for suppressing fluctuations in the liquid level of a continuous casting mold includes the following steps:

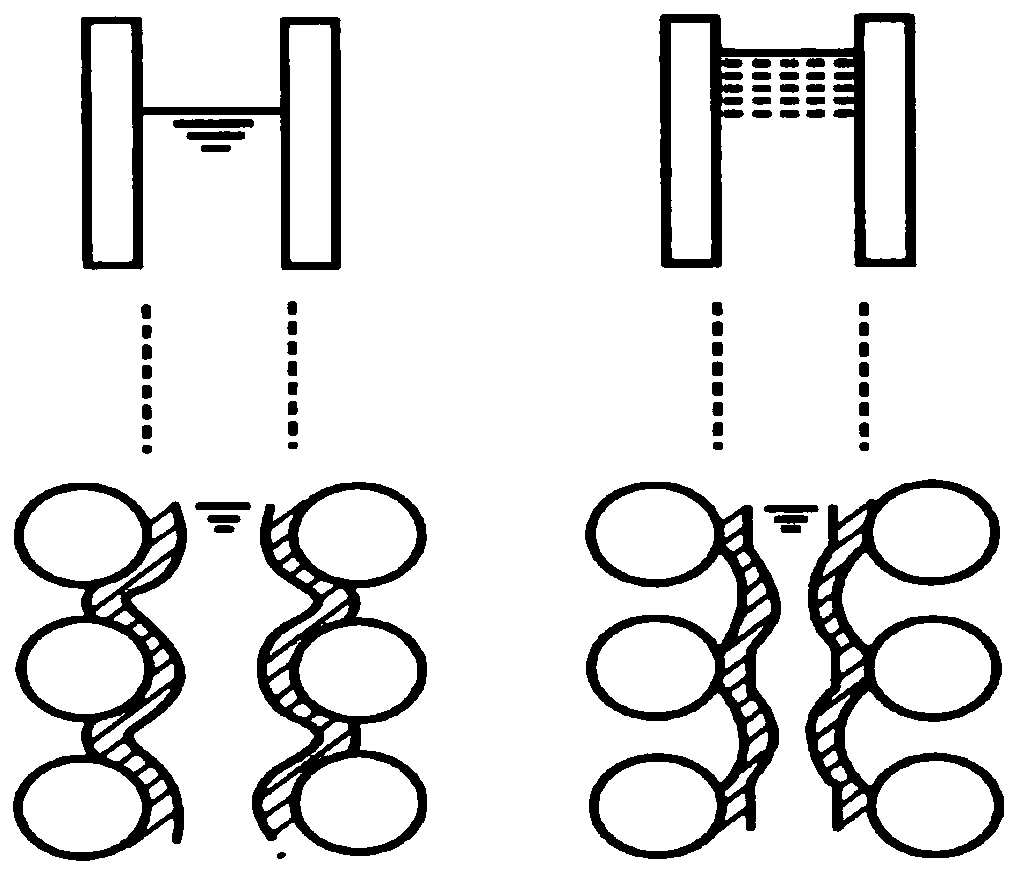

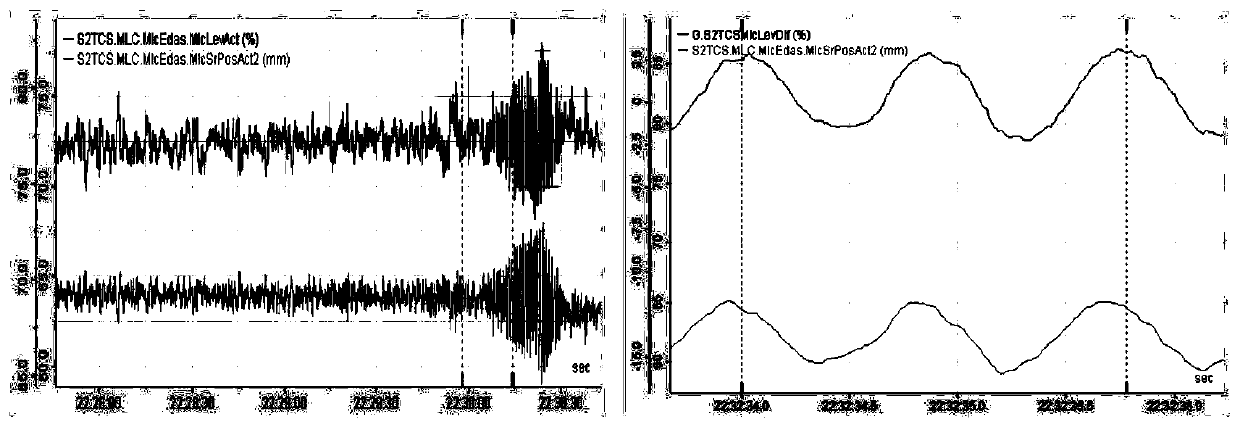

[0016] A. Controlling the fluctuation superimposed frequency range caused by the unstable liquid level of the mold has the lowest interfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com