Coal powder removal method in coal seam gas exploitation pipeline

A technology for coalbed methane and pipelines, applied in the direction of cleaning methods and appliances, chemical instruments and methods, cleaning appliances, etc., can solve the problems that affect the gas production process and efficiency, cannot understand the detailed conditions in the well, and consume a lot of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

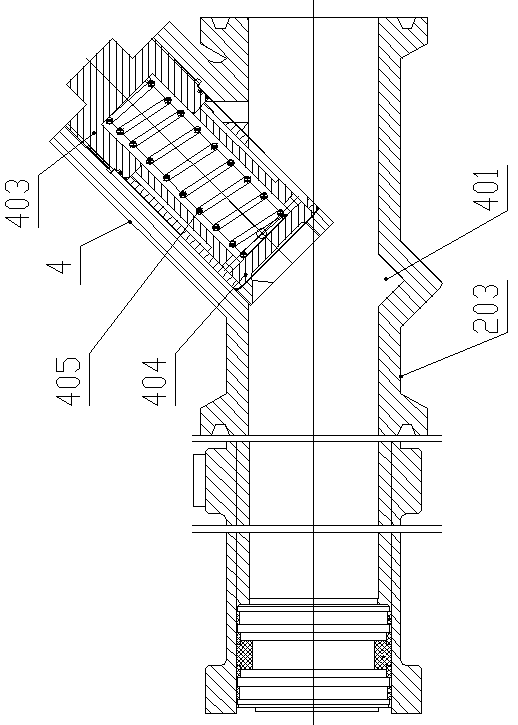

[0041] like Figure 1-Figure 6 As shown, the method for removing pulverized coal in the coalbed methane mining pipeline of the present invention comprises the following steps:

[0042] Step 1, put the pipeline robot into the pipeline 6 of coalbed methane mining, the controller on the ground controls the walking mechanism of the pipeline robot to contact the inner wall of the pipeline 6, and then start the walking mechanism to move forward along the inner wall of the pipeline;

[0043] Step 2, while the pipeline robot is traveling on the inner wall of the pipeline, the pipeline robot is controlled to carry out a rotating removal operation to remove the pulverized coal attached to the inner wall of the pipeline 6;

[0044] Step 3: Control the pipeline robot to collect and store the cleaned pulverized coal;

[0045] Step 4: compress the stored pulverized coal, and squeeze out the water, so as to collect more pulverized coal during the removal operation;

[0046] Step 5. When th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com