A pipeline robot dedicated to removing coal powder from coalbed methane mining pipelines

A pipeline robot and coalbed methane technology, which is applied in the direction of cleaning equipment, earth cube drilling, cleaning hollow objects, etc., can solve the problems that affect the gas production process and efficiency, consume a lot of energy, and cannot understand the details of the well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

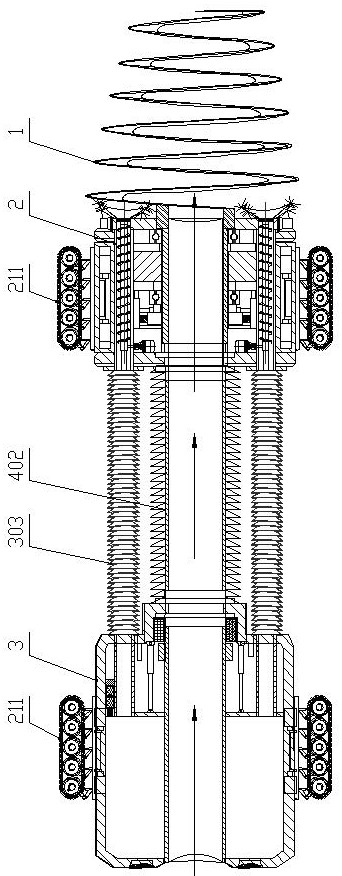

[0027] Such as Figure 1-Figure 6As shown, the pipeline robot of the present invention dedicated to removing coal powder in the coalbed methane mining pipeline includes a desilting device 1, a driving device 2 and a storage device 3, and a power module 216 is arranged in the driving device 2 and the storage device 3 to clean The silting device 1 is arranged on the front end of the driving device 2, the outer shape of the driving device 2 and the storage device 3 is cylindrical structure, and the center of the driving device 2 and the storage device 3 is provided with a water hole through which the front and rear are transparent, and the passage in the driving device 2 A central water hose 402 is connected between the back end of the water hole and the front end of the water hole in the storage device 3, and several pulverized coal delivery hoses 303 are arranged between the rear end of the drive device 2 and the front end of the storage device 3 , the pulverized coal conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com