Modified attapulgite clay and preparation method thereof

A modified technology of attapulgite clay, applied in chemical instruments and methods, other chemical processes, inorganic chemistry, etc., can solve the problems of limited adsorption effect of metal strontium ions, achieve good adsorption effect, change surface structure, and improve adsorption performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

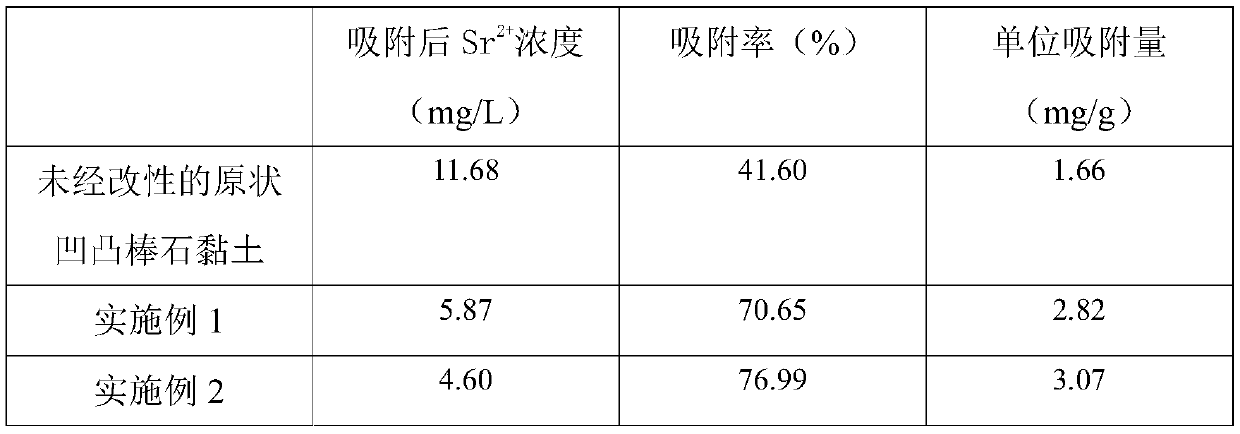

Embodiment 1

[0031] A preparation method of modified attapulgite clay, comprising the steps:

[0032] 1) Purification of attapulgite clay:

[0033] a) Pulverize 2g of attapulgite clay with a pulverizer, pass through a 100-mesh sieve, then place it in a 200ml beaker, add 80g of deionized water and 0.06g of sodium hexametaphosphate, and magnetically stir for 30min to obtain a mixed solution;

[0034] b) Disperse the mixed solution in an ultrasonic instrument at 25°C for 1 hour, take it out, place it in a centrifuge tube, and centrifuge it at a speed of 3300 rpm for 15 minutes to obtain dehydrated attapulgite clay, and place the dehydrated attapulgite clay in Dry in an oven at 105°C for 3 hours to obtain dried attapulgite clay, grind and pulverize the dried attapulgite clay, and pass through a 100-mesh sieve to obtain purified attapulgite clay. Put the stone clay in a ziplock bag and keep it sealed for later use;

[0035] 2) Weigh 0.8g of cetyltrimethylammonium bromide, place it in 80ml of ...

Embodiment 2

[0038] A preparation method of modified attapulgite clay, comprising the steps:

[0039] 1) Purification of attapulgite clay:

[0040] a) Pulverize 2g of attapulgite clay with a pulverizer, pass through a 100-mesh sieve, then place it in a 200ml beaker, add 80g of deionized water and 0.06g of sodium hexametaphosphate, and magnetically stir for 30min to obtain a mixed solution;

[0041] b) Disperse the mixed solution in an ultrasonic instrument at 25°C for 1 hour, take it out, place it in a centrifuge tube, and centrifuge it at a speed of 3300 rpm for 15 minutes to obtain dehydrated attapulgite clay, and place the dehydrated attapulgite clay in Dry in an oven at 105°C for 3 hours to obtain dried attapulgite clay, grind and pulverize the dried attapulgite clay, and pass through a 100-mesh sieve to obtain purified attapulgite clay. Put the stone clay in a ziplock bag and keep it sealed for later use;

[0042] 2) Weigh 0.8g of cetyltrimethylammonium bromide, place it in 80ml of ...

Embodiment 3

[0045] A preparation method of modified attapulgite clay, comprising the steps:

[0046] 1) Weigh 0.8g cetyltrimethylammonium bromide, place it in 80ml absolute ethanol, stir to dissolve cetyltrimethylammonium bromide in absolute ethanol to obtain hexadecyltrimethylammonium bromide Trimethylammonium bromide ethanol solution;

[0047] 2) Add 2g attapulgite clay to cetyltrimethylammonium bromide ethanol solution, stir for 3 hours, then add phosphomolybdic acid aqueous solution (the concentration of phosphomolybdic acid in the described phosphomolybdic acid aqueous solution is 0.20mol / L, the mol ratio of phosphomolybdic acid and cetyltrimethylammonium bromide in the described phosphomolybdic acid aqueous solution is 1: 1.2), continue to stir for 3 hours, carry out sonication after stirring (the sonication temperature is 25°C, the ultrasonic time is 3 hours), the solution after ultrasonic treatment is suction filtered, and the filter cake is washed with deionized water until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com