Cigarette filter tip defect online detection device of cigarette making and plug assembling machine and methodthereof

A technology of defect detection and coiling machine, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., to achieve the effects of convenient installation and debugging, improved test accuracy, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

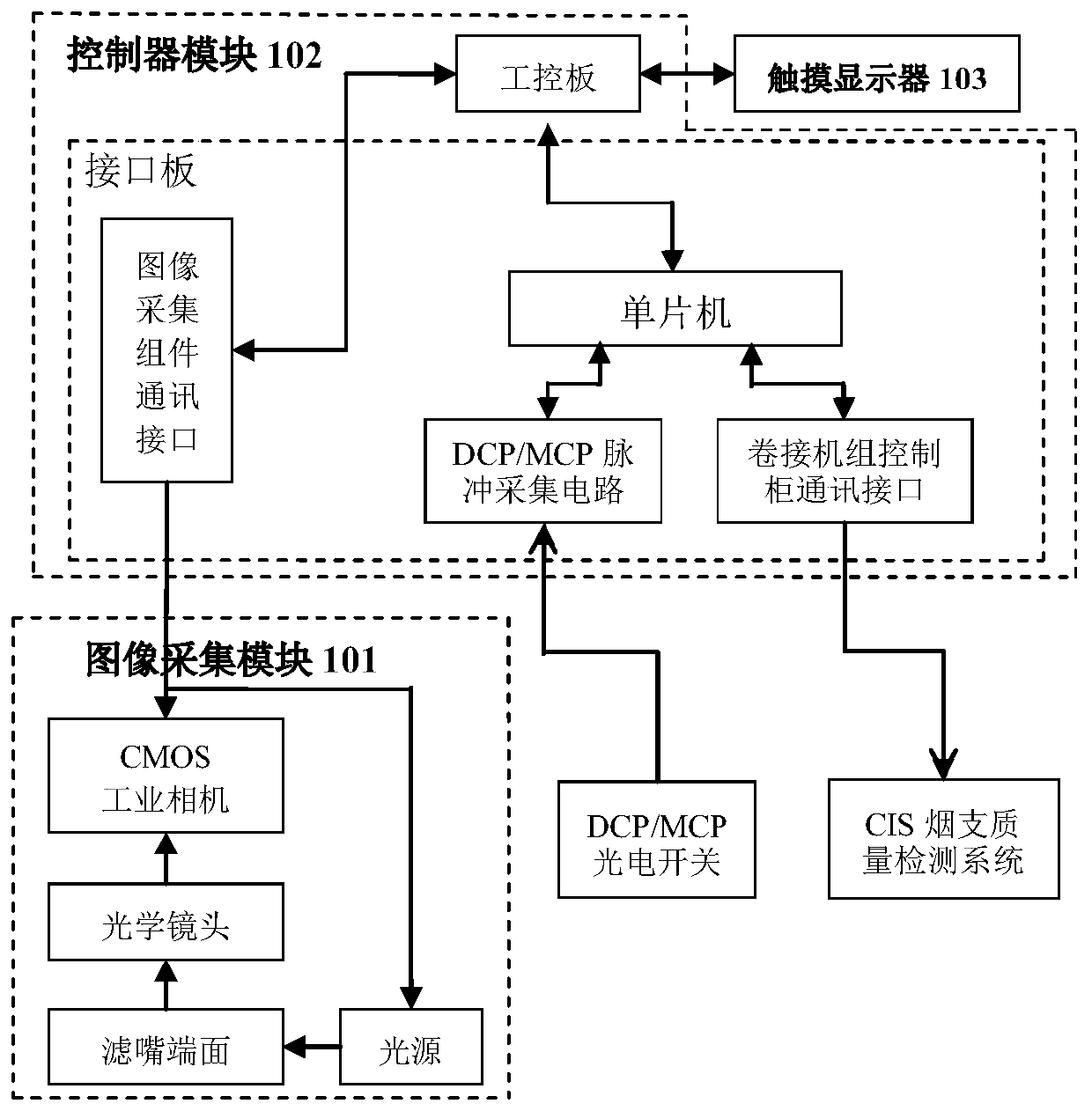

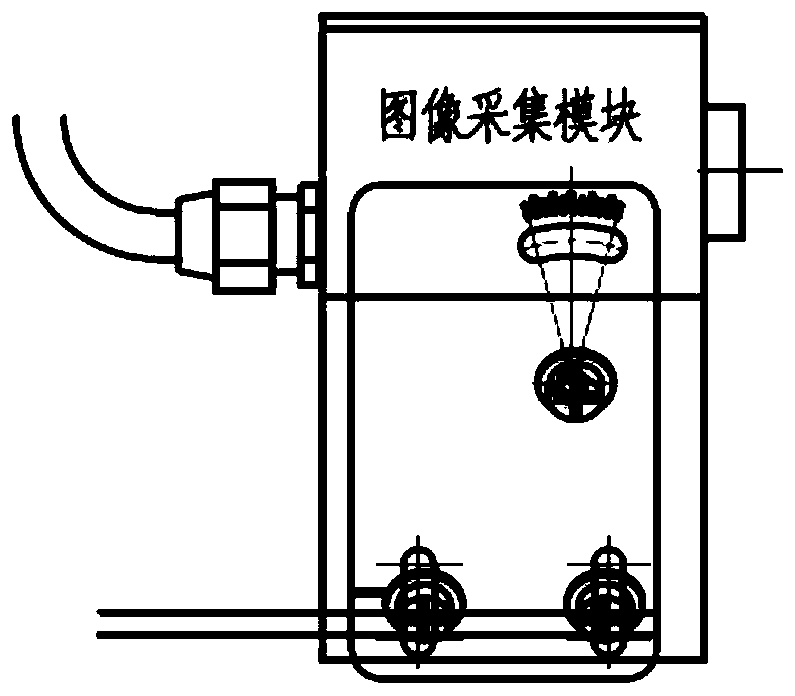

[0039] Such as figure 1 As shown, this embodiment provides an on-line inspection device for cigarette filter tips of a crimping machine based on machine vision technology, including an image acquisition module 101 , a control module 102 and a touch screen 103 . The image acquisition module 101 is responsible for collecting the image of the end face of the cigarette filter through the industrial camera and sending it to the control module 102 after preliminary processing. It is responsible for both supplementary light and image acquisition. It is mainly composed of light source, CMOS industrial camera, optical lens and light source bracket and other components. The control module 102 processes the image collected by the image acquisition module 101 through image processing technology and judges whether the depression pattern of the cigarette fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com