Twin-spool turbojet engine having low-pressure shaft thrust bearing positioned in exhaust casing

A turbojet, low pressure turbine technology used in engine components, engine functions, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

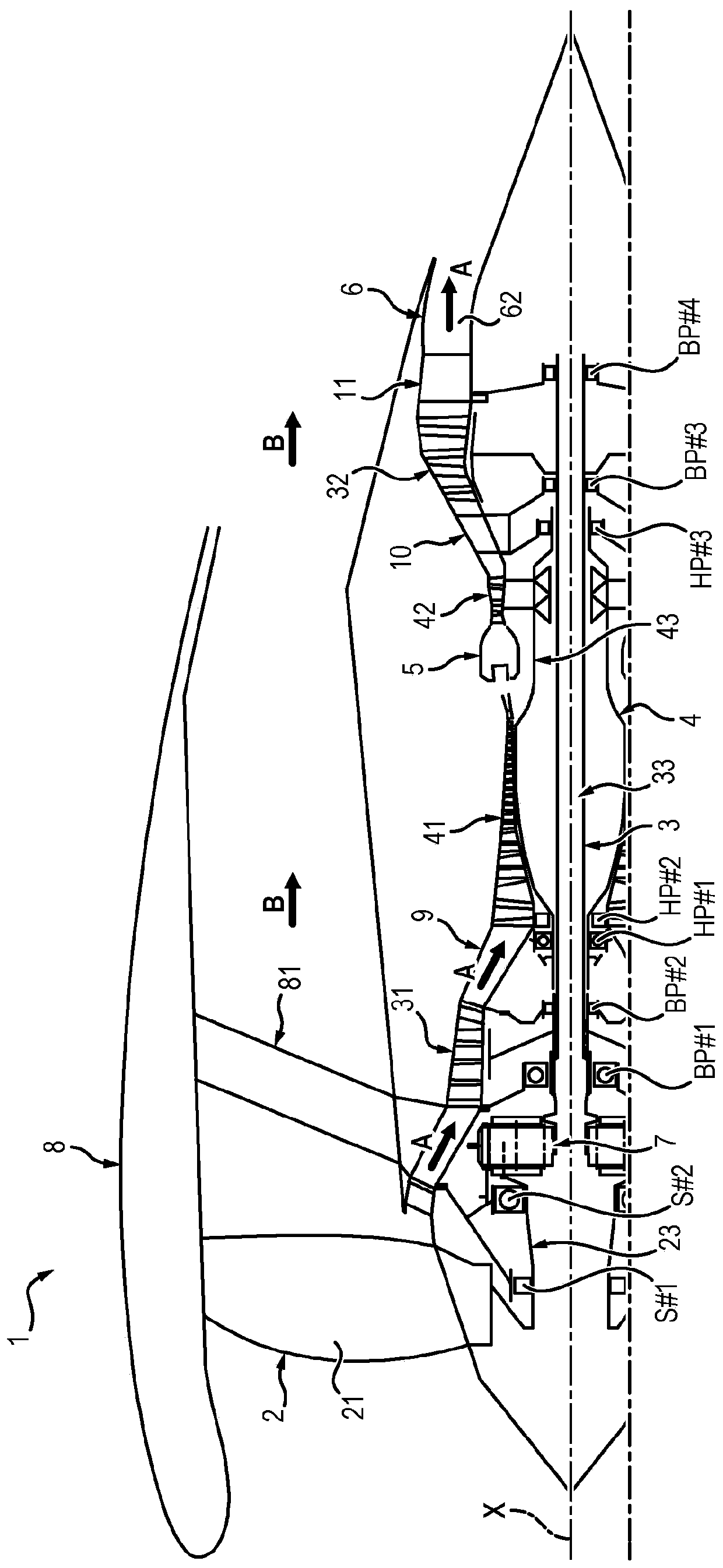

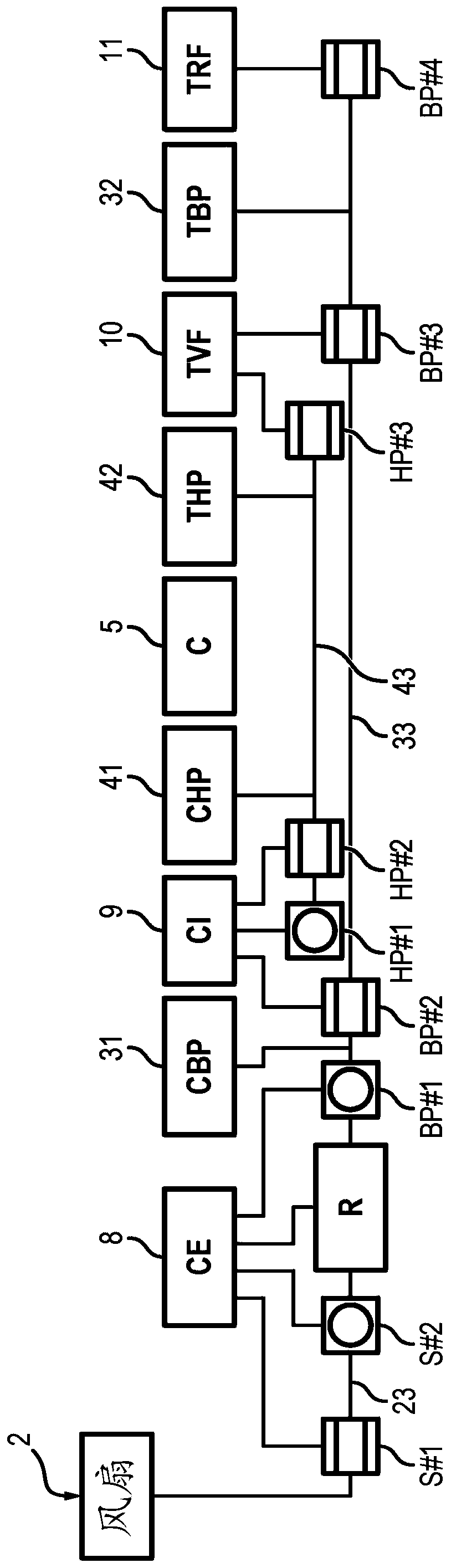

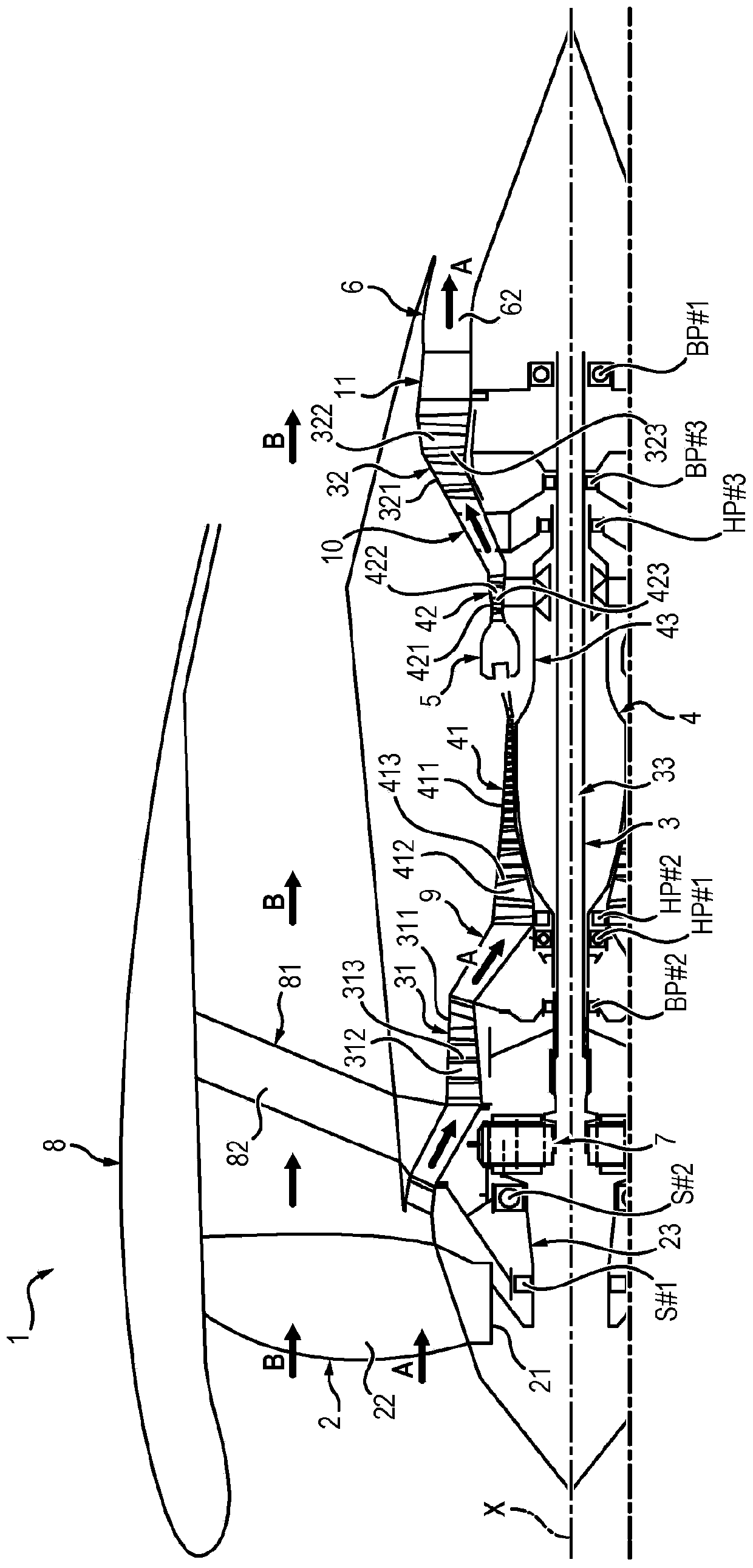

[0070] exist image 3 and Figure 4 , a turbojet engine 1 is shown comprising a fan 2 , a low-pressure swivel 3 , a high-pressure swivel 4 , a combustion chamber 5 and an exhaust nozzle 6 .

[0071] The fan 2 comprises a fan disc 21 provided at its perimeter with fan blades 22 which, when rotating, drive air to flow in the primary and secondary flow spaces of the turbojet 1 .

[0072] The low-pressure swivel 3 includes a low-pressure compressor 31 , a low-pressure turbine 32 , and a low-pressure shaft 33 coupling the low-pressure turbine 32 to the low-pressure compressor 31 .

[0073] The high-pressure swivel 4 includes a high-pressure compressor 41 , a high-pressure turbine 42 , and a high-pressure shaft 43 coupling the high-pressure turbine 42 to the high-pressure compressor 43 .

[0074] The low-pressure shaft 33 extends inside the high-pressure shaft 43 . The low pressure shaft 33 and the high pressure shaft 43 are coaxial. The low-pressure shaft 33 and the high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com