Automatic point grinding device

A technology of equipment and power device, applied in the field of automatic research equipment, can solve the problems of low degree of automation, cumbersome operation, low efficiency, etc., and achieve the effect of solving cumbersome evaluation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

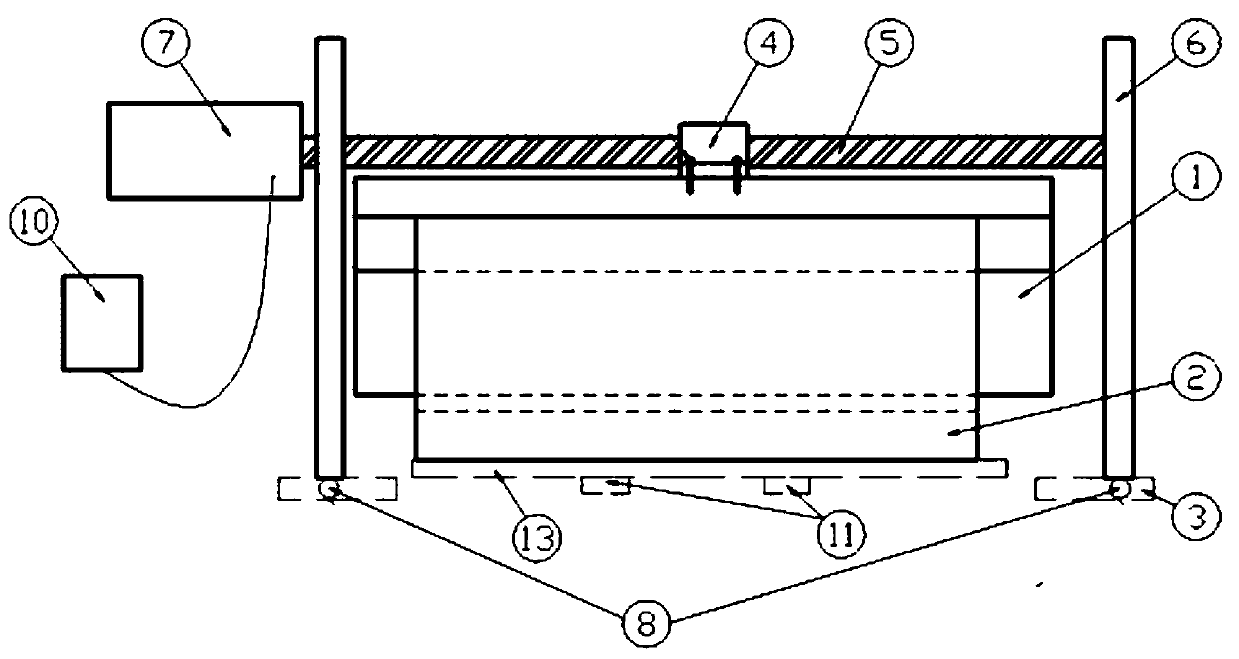

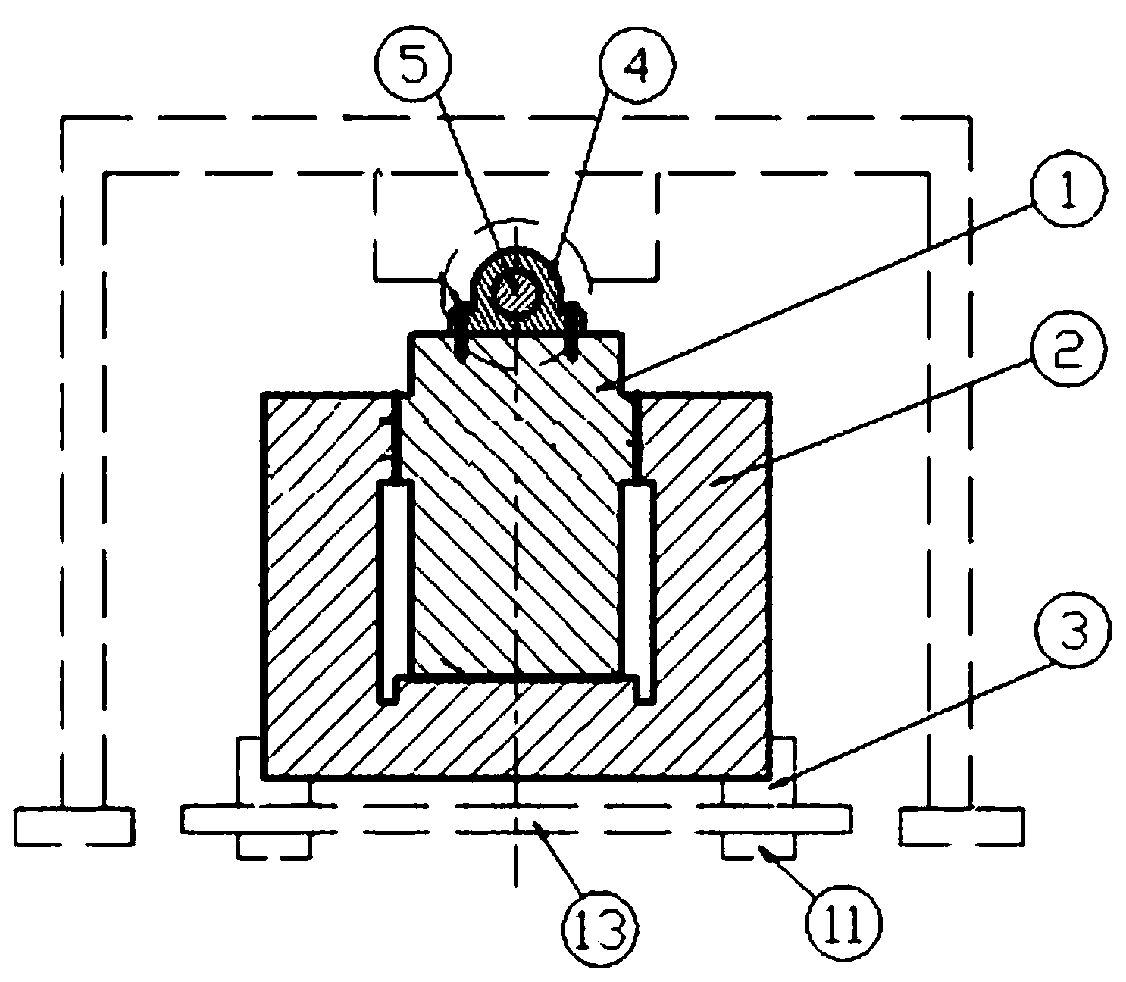

[0023] As shown in the figure, a kind of automated research equipment, the provided automated research equipment includes a base 3 installed on the ground, the bottom of the base 3 is provided with a pressure sensor 8, the pressure sensor 8 detects the base 3 and The total weight of the equipment carried by it can be obtained by subtracting the self-weight of the equipment to obtain the load of the external force. The automatic research point equipment also includes a support frame 6 arranged on the base 3, a ball screw pair arranged on the support frame 6, a power unit 7 arranged on the support frame 6, an electric motor set on the support frame 6 The control system 10, the workbench 13 arranged on the ground and several groups of jacks 11 arranged at the bottom of the workbench 13.

[0024] Described base 3 is four groups, and four groups of bases 3 are distributed on the four corners of a rectangular figure on the ground, and described support frame 6 is n shape, and each s...

Embodiment 2

[0030] Further, according to different workpiece structures, research point requirements and factory production needs, the worktable 13 of the research point equipment in this case can be transformed into a 360° indexable and fixed movable workbench, in order to achieve 360° rotation , the workbench 13 includes a base, a top plate arranged above the base, and a rotating rod arranged between the top board and the base, the lower surface of the top plate is provided with a counterbore for installation, the lower end of the rotating rod is fixedly connected with the base, and the rotating rod The upper end is inserted into the installation sink of the top plate. The rotating rod is perpendicular to the horizontal plane, and the axis of the mounting counterbore passes through the center of gravity of the top plate.

[0031] Realize the automatic following of the direction during the grinding point, no need to consider the installation direction between the first workpiece 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com