Auxiliary device for mounting mold and mold mounting method using same

A technology of an auxiliary device and a mold is applied in the field of the auxiliary device for installing the mold and the installation field of the mold using the same, which can solve the problems of increasing the cost of importing the mold, costing the cost, and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

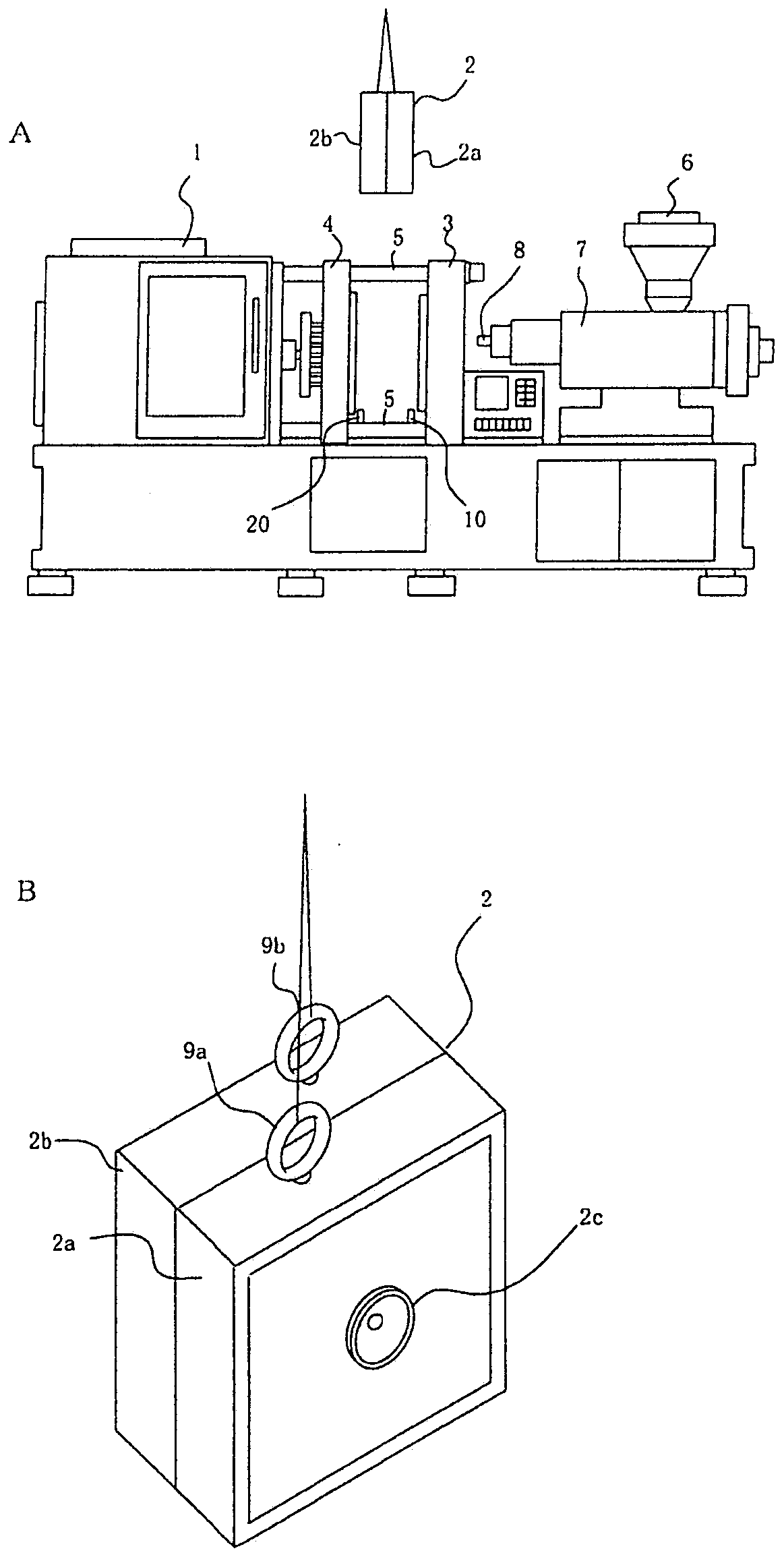

[0052] figure 1 A state in which the mold 2 is set in the injection molding machine 1 is shown. exist figure 1 In A, the injection molding machine 1 has a fixed side platen 3 and a movable side platen 4 . The movable side pressing plate 4 is guided by the rod 5 so as to be movable relative to the fixed side pressing plate 3 .

[0053] In the drawing, an injection unit 7 having a hopper 6 for inserting raw materials is arranged on the right side of the fixed side platen 3 , and an injection nozzle 8 is attached to the injection unit 7 . The injection nozzle 8 injects the raw material into the mold 2 through a hole (not shown) opened in the fixed platen 3 .

[0054] figure 1 B indicates the suspended mold 2. The mold 2 is suspended in a state where the fixed side mold 2a and the movable side mold 2b face each other. The suspension rings 9a and 9b are provided at respective one positions on the diagonal line of the fixed side mold 2a and the movable side mold 2b. The mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com